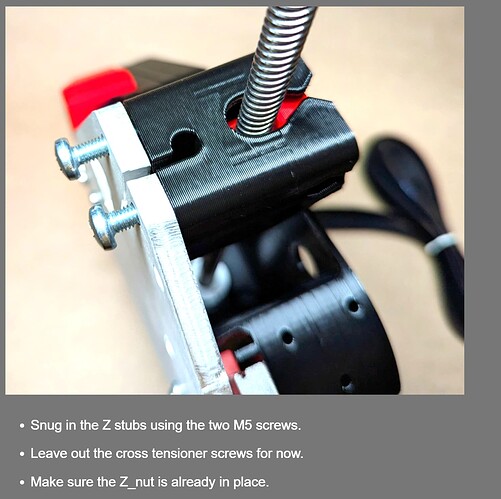

Hello there. So I have my machine set up, and trying to zero things in. As I was checking over everything again, I realized that during the build it tells you to leave out some cross tensioner screws that I think connect the z_nut to the Z_stubs. Are you supposed to enter these tensioning screws later? I could not find anywhere in the directions that they were added, but by all means, please tell me if I’m missing something.

Right now I believe Ryan is telling everyone to leave this screw out. I put the screw in for my builds but only to the point that the end of the M5 touches the nylon on the nut. Which leaves it lose to move as needed. But I would suggest just leaving it out as he suggest. I only put it in for shipping/customer assembly reasons.

Whats the idea behind not including the nut. Doesn’t this let the assembly pushed up when pushing down on the table with the router bit? Or is this a safety mechanism, since the weight of the bar should be plenty?

Different nut…

The nut that holds the plastic assembly in place locks in the offset to the motor. If this is exactly correct, no problem, but if it is even the slightest bit off, it becomes a large problem. Leaving the screw in place (loosely held in by the printed plastic part) but no nut allows the piece with the lead screw nut to move a little bit, which allows it to self-adjust to the actual position of the Z motor and any bend/warp in the Z lead screw – up to a certain point.

FWIW, I do have the nut on the screw, but it’s loose enough to still allow the self adjustment.

Hmm doesn’t the docs say leave the screw out, not just the nut?

Very possibly. I built mine during the beta phase, and have only skimmed over the docs.