Longer tests show that the drivers are not too far off voltage-wise. I had them run on 2.5A for a longer time and they reached 50°C, so I went down to 2A again (which, realistically, is a bit more than 1.8A it seems, so should be perfect). None of those changed the dropping though.

It seems I have found the solution: Slow down Z to a crawl (500mm/min) and inertia to 99% (you can ignore this, it’s Estlcam) and it seems there is no more dropping.

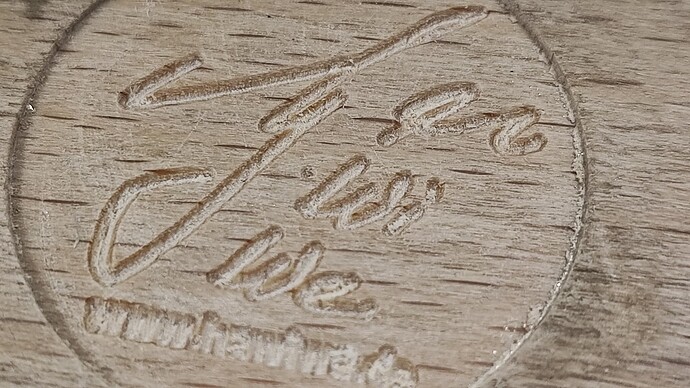

Does anyone of you want do do a Z drop test and mill those little doves with all the ups and downs and check whether it is at exactly 0 after 15 minutes? @azab2c maybe. Or @vicious1, to prove it’s me and not the machine? ![]() If yes, take any pointy endmill and start from the M06 command (bit change) where it starts with those carves.

If yes, take any pointy endmill and start from the M06 command (bit change) where it starts with those carves. ![]()

Schneidebrett Yvonne Inlay.zip (67.0 KB)

What does inertia mean in estlcam again? Isn’t that accel? Z accel need to be lower than XY for sure.

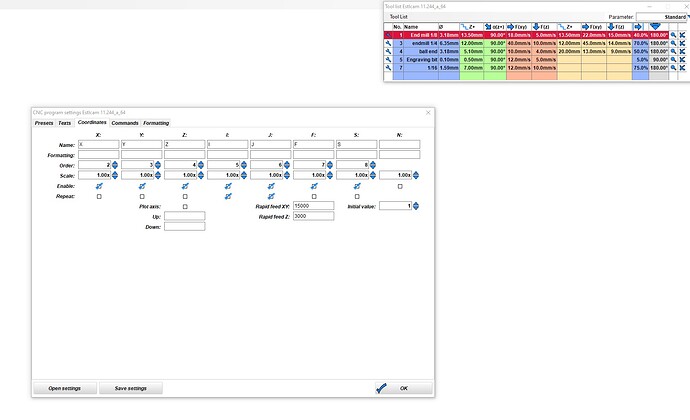

No, it’s deceleration. It slows down to 1% before stopping instead of abruptly. If I set it to 60%, it would slow down to 40% before changing direction. Normal value is 85% there, but the heavy Z with ganrty seems to need it lower. Maybe I’d get away with 90 or 95, but if it works, it works. ![]() Hopefully. Will see tomorrow or later when I do the next cut.

Hopefully. Will see tomorrow or later when I do the next cut.

Is there a setting for acceleration as well? That seems more important than decel.

1-5% seems kinda normal, we have it set to a 3mm/s jerk I think so that is about right.

I can, just not sure how to test the position accurately. Maybe probe before and after?

Thanks for getting back to me. ![]() If it is really dropping you are going to see it immediately. If you probe at the start and then, after 10 minutes, drive the LR back to 0,0 but keeping it at save distance (3mm), then lowering it, you would see that the tip touches the spoilboard at around 0.3, not 0. It’s pretty hart to miss.

If it is really dropping you are going to see it immediately. If you probe at the start and then, after 10 minutes, drive the LR back to 0,0 but keeping it at save distance (3mm), then lowering it, you would see that the tip touches the spoilboard at around 0.3, not 0. It’s pretty hart to miss.

Oh, and if you really have the time to do it, set the Z speed to 1200mm/min. That would be my testing ground. ![]()

Yes, it starts with 20mm/min (speed) and then takes 60mm (distance) to reach max speed. It’s a curve, not a line though. I set those pretty low. The tooltip says that if you lose steps slowly to increase inertia, if you lose steps abruptly you should change max speed and accelleration, which is definitely not the problem. The weight of the gantry seems to limit max speed as well since it is harder to catch the weight when going the other way and those carves have a looot of ups and downs. ![]()

Holding power is not the problem though, I put a lot of my body weight on the gantry before it dropped, so the holding torque seems to be okay. It’s just got a problem with me rotating it with my two hands. ![]()

@Jonathjon What is your Z speed for rapids? You having the spindle would be a good benchmark as well since it’s even more heavy. ![]()

I am not having Z issues. I run my daily cuts at a plunge of 15mm/s and rapids at 50mm/s(3000mm/min). Most of my cuts are 0:20-1:20 long.

I have a hour twenty job to cut and some table leg sets, I might be able to test this tonight but I run my daily jobs much harder than your settings. As far as I know, no Z issues.

Your jobs are mostly cutting LR plates, right? That’s not too much Z movement. I am not sure one would see a drop there, but you never now. Those rapids are insane though, thanks for showing me that this should not be a problem. And the weight difference of a full gantry should not change it either, it’s just a bit of metal. ![]() I really am at a loss what the problem is. Shouldn’t be the drivers either because I’ve been using them for three years, but then most of that time with a Primo, whose core is considerably less heavy.

I really am at a loss what the problem is. Shouldn’t be the drivers either because I’ve been using them for three years, but then most of that time with a Primo, whose core is considerably less heavy.

Like I said, I added 20 pounds to my LR2, AZA made a custom build to add weights to his. Weight is not an issue these steppers are monsters.

Best I can say is tuning. Obviously you can easily move faster, but the accel and decel are not sounding right to me, those are by fast the most important, that is where issues happen, not in the middle of a move unless you hit something.

If you are using estlcam12 it could be a bug in the program or the firmware. I suggest testing with V11.

I have no experience with estlcam firmware but I I know marlin and grbl have serious work put in to accelerations. S curve, jerk, junction deviation .

I do set my cuts to 0.2-0.3mm over the material size. So if it went shallower I am sure I would notice, deeper not so much. An I run that nearly daily. I am pretty confident I would notice it.

I am trying to think of a way to do a test, though. I will drop some more weights on mine and do some speed and repeatability tests if the probing makes sense.

Crud…I currently have an NDA situation though and can not make a video easily. If I have time tonight I will make some swaps and try it.

No worries. ![]() Thanks a lot, I will play around a bit more with the settings. Maybe I am overlooking something very obvious. I will also test with something that are not carves. The fact that you don’t have problems with much less A on the steppers is something to think about.

Thanks a lot, I will play around a bit more with the settings. Maybe I am overlooking something very obvious. I will also test with something that are not carves. The fact that you don’t have problems with much less A on the steppers is something to think about. ![]() Your time is too valuable to try that! I will come back crying for more help in a few days after it also didn’t work.

Your time is too valuable to try that! I will come back crying for more help in a few days after it also didn’t work. ![]()

I filmed a little clip, I will upload it this evening.

Using your GCode and putting two sanders on it (around 6kg) I did not have a drop. I also upped the speed to 800mm/min.

I think it did drop again a bit when running my birds, but no way to test without actually cutting them and I didn’t have the time. But if they still drop it can only be a hardware problem, because obviously it’s not the LR and not Estlcam, because it’s the same settings. It isn’t the computer either. Could it be the stepper drivers, not making the changes quickly enough? But then again, looking at the GCode of the birds, X as well as Y should be off (and actually, X was off before which was solved with the inertia settings in Estlcam as well).

It is so hard to say. I am guessing tuning issues. You say you are having a repeatable 0.3mm offset thought? Skipped steps are almost never repeatable and almost always larger than that (at least one full step), and typically they add up so you would see a stairstep effect somewhere.

Have you remade the CAM itself, maybe there is a glitch there. V11 or V12?

It’s 0.3mm per 5 minutes, basically. So it does add up the longer it goes. ![]() But don’t know whether it’s still happening after the changes yesterday.

But don’t know whether it’s still happening after the changes yesterday. ![]()

I did upload the settings again and also installed a new version of Estlcam.

Sorry, I can’t let it go. You can see that Z is still losing steps when doing carves (but it seems, as we tested, only during carves.

Starting position:

After an 8-minute carve at 0.1mm depth:

The whole it leaves (so the amount it dropped):

How is that happening? Can someone please do the same carve and tell me it happens for them as well? ![]()

HaWiWe mit Internet.zip (36.9 KB)

Hmmmm, I see something similar in our FluidNC yaml, https://github.com/V1EngineeringInc/FluidNC_Configs/blob/main/MPCNC/config.yaml

stepping:

engine: I2S_STATIC

idle_ms: 255

pulse_us: 4

dir_delay_us: 1

disable_delay_us: 0

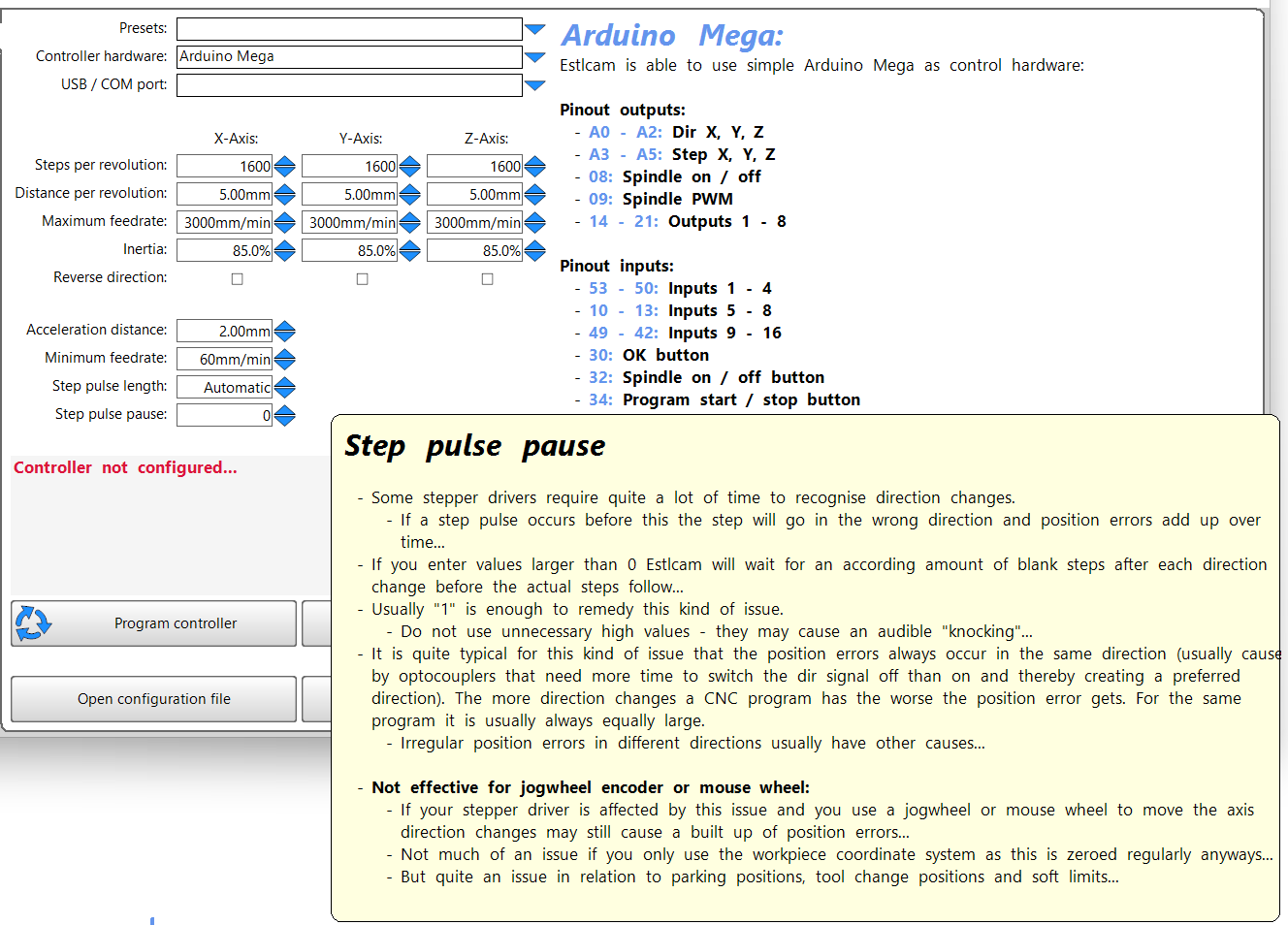

I have never tried to adjust these Pulse and Delay. Looks like our delay is 1, you can check the pulse length as well. see what automatic gives.

The fluid wiki has good info, Axes | Wiki.js

So the smaller the better, but it still needs to be enough. I wonder the best way to test this…It might even be a driver spec.