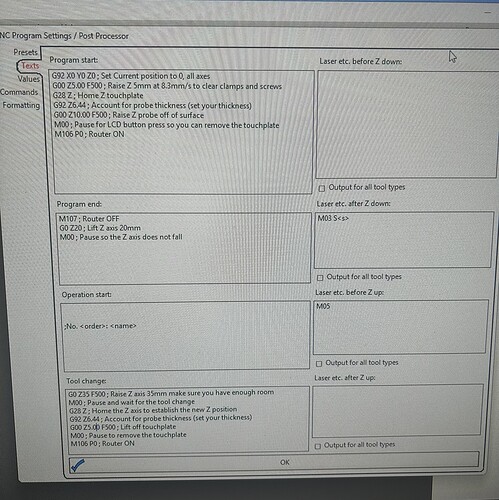

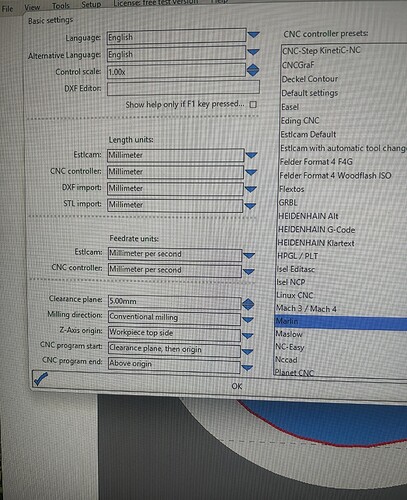

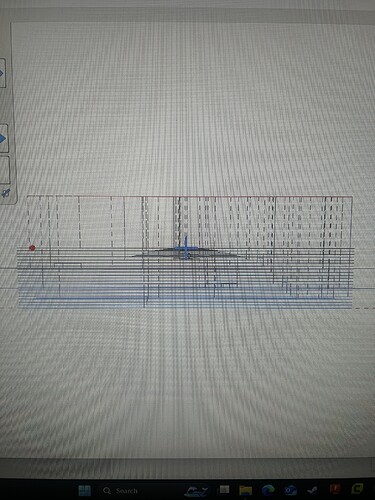

I’m back… I’m having issues with getting my Z-probe offset to work properly. I’m running an SKR pro, dual primo mpcnc. I put the thickness of the probe in the G92 code under the “program start” section in Estlcam, but when I start the cut, it starts cutting about 3mm above the cutting surface…what am I missing here?

Upload your gcode file so we can take a look. Your start settings look right. I am wondering if you are using a wrong setting when you set up your cut in estlcam.

Your Gcode looks right to me. Is the Z axis stopping as soon as the bit touches the plate? Meaning does it have a good connection? If its driving down farther before it actually stops then that could be the problem.

Hopefully someone smarter than me will take a look and find something I am not seeing.

Z stops as soon as it touches the plate. Thank you for checking it out! I’m sure the solution is staring me right in the face… have a good one ![]()

What does marlin report the Z position is after you manually run the probing sequence?

X0.0,Y0.0,Z0.0

I’m assuming the z-hight should be 6.44? Is there a setting I’m missing?

Right after your pause to remove the touch plate, insert a G0 Z0 and another pause. If the tip of the bit is just touching the surface of the stock, then your probing is working correctly, if it is not, then that is the root of your issue.

I did notice that you don’t have a G90 (absolute coordiantes) in your start code. I think absolute positioning is the default in Marlin, but, if your bit tip is not touching the stock with a G0 Z0, you might add a G90.

Thank you so much! When I did this, it came down exactly half the thickness of the probe so I checked my steps per millimeter for Z and they were half what they should be… everything seems to be working properly now

Dang. I never even thought about that being an issue. Great find! Glad you got it working like it should be!