If this is not allowed PLEASE Delete… I’m a Noob trying to get my Z to be correct. I’m using Estlcam & Jackpot. I got it right once, but not sure what I did I would like to find someone familiar with my setup that would be willing to msg or text with me. This Forum is Fabulous,but it may take a day for a reply, I’m guilty as charged my email is. geoff.jones53 at gmail.com

Thanks in Advance

What’s wrong with the Z?

So what motors are you using? 1.8° or 0.9° per step?

What leadscrew? 8mm lead or other?

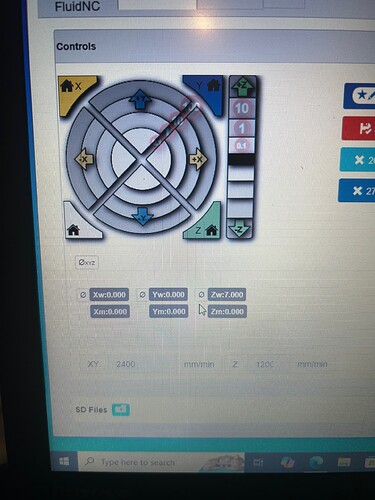

What control board? Firmware? Control screen or LCD? How are you sending jobs?

Can you be more specific? Are you trying to Home Z? Or are you trying to level Z1 and Z2? Or are you trying to set Z=0 after probing? Or something else entirely?

Also, really not a good idea to post your email address on a public forum. You may get some unwanted responses from bots, trolls and undesirables…

My machine is a MPCNC. I bought the build kit & Jackpot controller from V1 shop. I normally run it from my phone. I am using Estlcam to create my tool paths.

My problem is getting Z to cut deep enough. I’m presently cutting 4mm coroplast, to practice on. I probe Z to set 0, and when I start the part, Z only cuts about 3mm deep. I have my material thickness set to 5mm, with a 5.4mm cut depth in Estlcam. What am I doing wrong?

Did you put the proper settings in Estlcam from the milling basics page?

I didnt change / set the suggested ‘start g-code’. I thought that was what I was doing when I probed in FluidNC

no. When you probe in fluid it isn’t setting Z. Make the changes in estlcam. Drive the CNC to where you want X and Y zero to be and then start the G code. Then you will probe and it will set zero based off the thickness of the probe and you should be good to go. Are you using the V1 touch plate?

Yes to touch plate. I set thickness to .5mm. default was 5mm.

You don’t need to. If you put all the settings in estlcam then it will do it for you at the start of the job. And also will make it where you can re-zero Z on a tool change as well

I will Definately give that a try.

SHAME on me, Noob mistake. In estlcam I had Z orgin set to Machine bed. Setting to Workpiece top solved my issues. Thanks to everyone, I have learned ALOT!!

Awesome! Glad you got it figured out!

No need to be shame ![]() there is many origin in cnc world. And I have seen these might be difficult. You might have workplace coordinates G54-59, machine coordinates (machines have usuallu their own origin) and workpiece coordinates(which you set in cam from where to start and “count”). I’m glad that you did solve your problem

there is many origin in cnc world. And I have seen these might be difficult. You might have workplace coordinates G54-59, machine coordinates (machines have usuallu their own origin) and workpiece coordinates(which you set in cam from where to start and “count”). I’m glad that you did solve your problem ![]()

Just for Confirmation… Im about to start on a fresh piece of coro. In an area of 48" x 48" I have about 6 different things to cut. I have my Machine xyz=0, where ever I move my spindle, I can set the x&y to Workpiece = 0 and the cut would start there? Did I get it or what did I miss… TIA

We had a thread about it once where the conclusion was: “Home is where your part is.” So yeah, if you say it’s 0, it is 0. ![]() The machine does not think.

The machine does not think.

So wherever its parked when the cut file starts ?

That depends on your starting g-code. I use a starting g-code with fluid that sets the program to 0/0/0 when I start it, I have no idea what that is though and I can’t check at the moment, I usually use another controller.

No.

These CNC machines are dumb. They know exactly what you tell them and nothing more just like (insert whichever political party you want here to start an argument :laugh: ). When you first turn on the machine, wherever the tool is, is 0. The machine thinks that exact point is bottom left of your work area and it will keep thinking that’s 0,0 until you tell it otherwise.

Typical work flow 1. Turn on machine 2. home machine.

Homing (assuming you’re using end stops) will move the machine to the bottom left corner and reset that position to 0,0. Everything will work from that position unless you change it.

-

if you’re aligning your material piece to bottom left and your cut is set to origin there you can ignore this step. If your file is setting origin to anywhere else you need to tell the machine where to start. In that case you move the tool to where you want it to start indexing the cut from, and then set the work origin to that position. You’ll have machine 0,0 (bottom line of the x/y/z) and then you’ll have work 0,0 (top line). You can also move this step to after 4 and before 5.

-

Place material to be worked. 5. Probe.

Probing (assuming your software is set to 0 off of work surface) will tell the machine where that surface is and set your Z to 0 there. You need to make sure your probe offset is set to the same as the thickness of your touchplate or else your cut depth will be wrong. So now you’ve got 0,0,0. -

Start cutfile.

I forgot 6 since you’re new.

6. Ask out loud, Ok, why the hell did you do that?

Once you’re more experienced:

6. Ok, I screwed that up.

Followed by:

7. Go to the forum and ask “Ok, what did I screw up here…?”