I am not using touch plates.

Start of gcode looks like this:

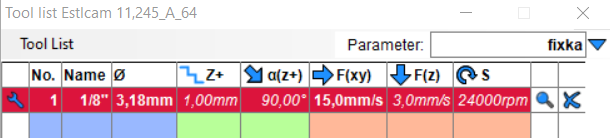

these are the settings I am using in Estlcam

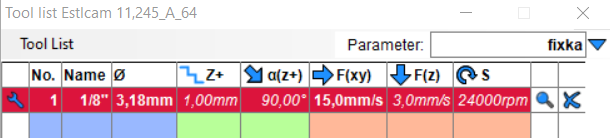

I tried my best to follow tutorial in docs, these settings in Estlcam looks different from what is in tutorial, which is this:

I am not using touch plates.

Start of gcode looks like this:

these are the settings I am using in Estlcam

I tried my best to follow tutorial in docs, these settings in Estlcam looks different from what is in tutorial, which is this: