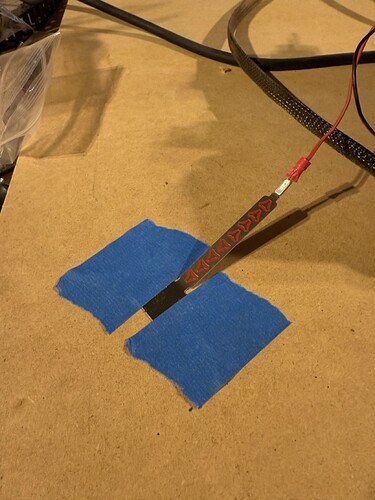

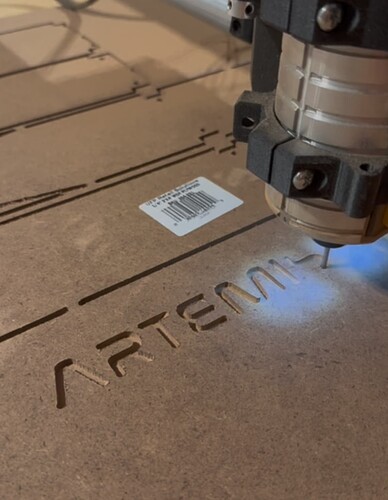

Hello, everyone! I’m building a LR4, and so far, things are going really well. But I’m at the point where I need to make my first cuts for my strut plates, so I’m getting nervous and second-guessing myself. ![]() This is my first CNC, but I’ve done a lot of 3d printing and other DIY.

This is my first CNC, but I’ve done a lot of 3d printing and other DIY.

I’m trying to figure out what’s ‘normal’ when leveling my Z-axis using the V1E touch probe. On a recent calibration run, the probe triggered at Z-81.075 at X=0, and Z–81.835 at X=890mm (the right side of my travel). If I’m doing the math right, that means that the right side Z homes 0.76mm higher. So I added 0.76mm to the left side Z pulloff.

On my next run, I got Z-80.985 on the left, and Z-81.890 on the right. Am I just chasing too much precision and probably not holding the probe flat enough? If I go do 10 more runs, am I going to see a bunch of variance that makes me feel silly for trying to adjust pulloff to fix 0.76mm of error?

What’s normal for you? How repeatable is the probe measurement, and how much difference do you have across the travel of your X-axis?