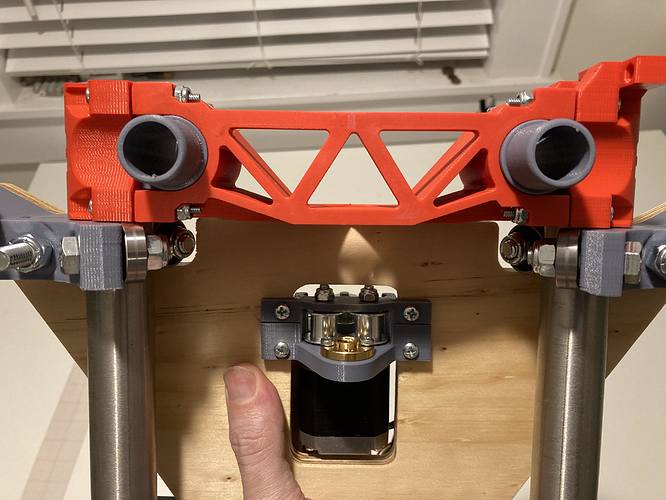

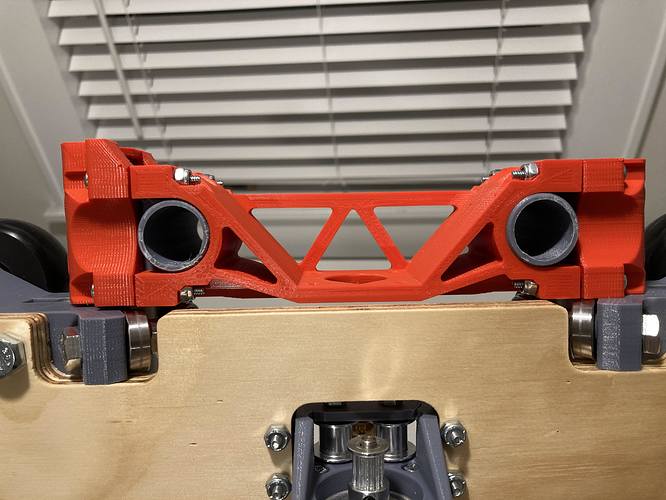

I have started assembling my first side plate and have an inconsistent gap around the outside edge of the XZ end caps. My max gap is about 2mm on one side of one of the end caps but the other side is only about .5mm off of the roller. I don’t know where this gap is coming from. It seems like the XZ end caps should be constrained with the Z tubes. The YZ rollers are square to the plate.

These are hand cut plates.

Troubleshooting from the docs:

- Double check that the Z rails are parallel, same distance apart at the bottom as they are on the top.

- If you loosen the corner brackets up too much and the XZ mains still won’t sit flat the larger bolts are not tensioned properly / evenly (probably way way too much).

- Make sure all four notches are above the end of the Z rails.

My Z rails are out of parallel by about 1.5mm over a 340mm tube length but it seems to roll well without the leadscrew installed. Since these plates are hand cut I assume that they are the source of my the error.

Is this a big enough issue to stop the build or should I press on so that I can have the LR2 cut new plates?

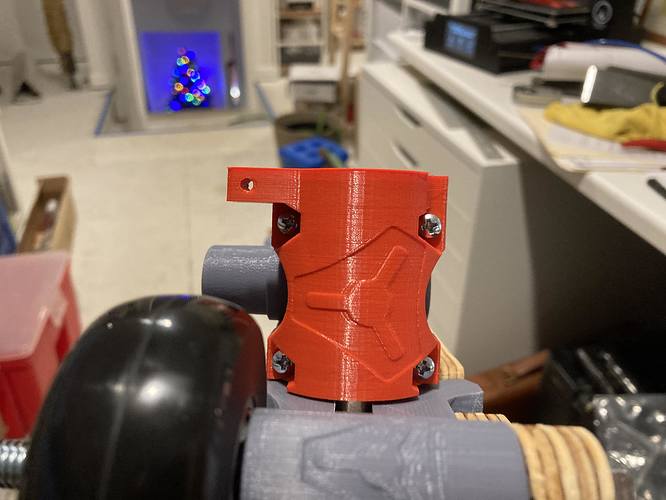

One other question is when I have the lower roller assemblies snugged up so that rotating each bearing on the assembly moves the tube rather than slipping, i can still fairly easily tweak the rotation of the printed piece against the plate. Is this as it should be or do i need to tighten the through bolt more even though its possibly going to over tighten the bearings?