I’m rebuilt a table for my lowrider 2 but ended up making just a half a millimeter too thick so there was always a 50/50 chance it’d skip steps. Decided to upgrade to the 3, procrastinated until the four came out and decided to actually build that one instead. Seemingly going well so far, though I did have an issue printing out the core. I decided to risk it anyways after printing the second time and everything seemed to fit pretty well.

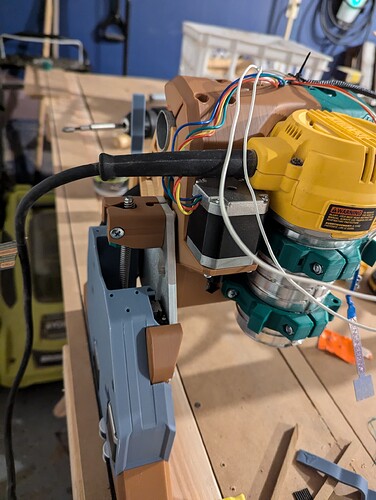

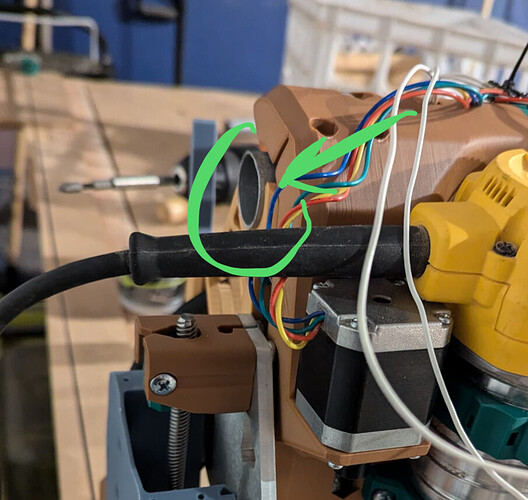

That is until I tried homing x. It doesn’t look like the screw is going home to its hole which won’t allow the x switch to trigger. I’m using a rambo board and the LED light on the board does go off (trigger) when I depress it with my hand. Y and Z homing is working fine so I’m pretty confident it’s this misalignment not allowing x to go far enough.

If this was somewhere else besides the first few layers and the rest of the parts didn’t fit well either, I’d try reprinting the core. However, the core fits on the main assembly fine and otherwise works moving around and the core takes a long time to print. The screw is just a little high and forward of the plate screw.

Printed my own parts, hardware and board from V1E. Could this be a different issue?