I don’t know if that makes me feel good or bad. Strange thing to me is I know the file that ran the crown the other day and definitely had Z movement picking up the pen between sections no longer does and I changed nothing that I know of. Coupled with not having much fun trying to get some support from China for my printer I think I should’ve bought more wine.

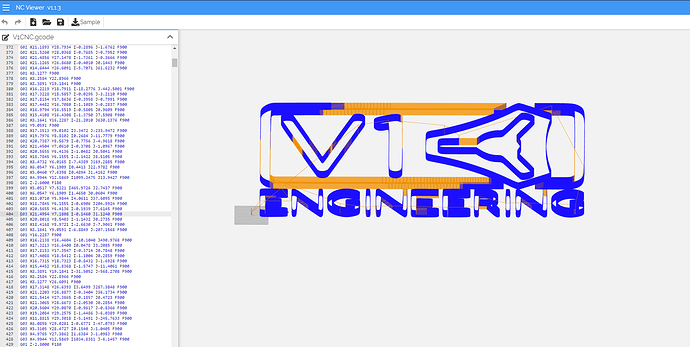

I don’t have a machine to test with right now. Maybe one of the other guys can when they get a chance, but the online gcode viewer shows it properly.

I’ve run it both expecting it to cut with the router on and dry above the material and the Z just won’t cooperate. I think I have a little acrylic around and if it worked I was going to cut it in acrylic, paint the back and add a little glitz to my machine, now I think it may be getting a little sign like-

CAUTION!: Electrickery In Use

I might be way off-base here, but did you Home the Z-axis? If you had the LCD connected it would flash “??” to show that it doesn’t know where zero is.

I haven’t hooked up the LCD yet but from what I read I’ve simply brought the tool to where I wanted (0,0,0) to be before powering up and sure enough the indicators read 0,0,0 when I hit the on switch, X and Y seem to be with the program and move accordingly as Z seems quite happy to stay home.

Curioser & Curiouser

When I downloaded Repetier Host it came as a package with R Server. Just out of curiosity I uninstalled server and just dry ran the program twice. Still no Z action but, both times I noticed not far into the program the Z indicator quickly flashed on -.4mm before returning quickly to 0 and staying there. Still confused but I know I wasn’t seeing things.

The depth of cut is set to 0.2mm. So each pass is going to go down only 0.2mm. If you look st Barry’s image, it is doing a ton of passes, and each one is very very shallow.

The one that looks like a Z+ is walking down some stairs, change that to 2mm.

No joy. I happened to load the crown in error but figured one should be as good as the other. Set that number to 2mm and dry ran it. Briefly saw 2.0mm on the Z indicator, quickly returned to 0, never saw a negative Z number. Said print was finished even though I could see it hadn’t done every tool path and then Repetier Host locked up, was unresponsive to the disconnect key, I shut power down before disconnecting. Rep Host wouldn’t close with the X in the upper right, had to right click on its icon to get it to close the window.

EDIT: I ran the V1 Logo again and let it go all the way to its finish. It clearly rises to the clearance plane between segments but I never saw anything but 0 in the Z indicator on the right side of the RepHost screen. Hard to tell by eye if it actually went below Z=0 but I doubt it. I’ll have to try it tomorrow with a piece of scrap but have to wonder what would make the X and Y numbers as it’s working seem correct while the Z remains at 0?

Maybe just ignore the indicator?

That’s gonna depend on whether with material in place it actually goes below Z-0. And I’m not really a big fan of unexplained anomalies if that’s what it is. Given that the indicator changes when Z is moved manually I think there has to be an answer somewhere.

I don’t use RH, but gcode is not magic. The same command in a gcode file that moves it up or down is used when you press the buttons to manually move it.

RH has a bad history of not knowing where Marlin thinks it is, so I would trust the LCD, or just the bit height, over an indicator in RH.

Nobody splained it to me like that. Is there something better to use?

Not really.

Maybe because I don’t really know how it can tell position, I’m guessing there are counters counting how many steps the motors have taken, it just makes me a little nervous that it knows when you move it manually and then loses it. Gives me visions of it just poking a hole right thru the table because it forgot where it was.

That is all happening in the firmware. The firmware has a good record of where it is. RH is just a remote control. It isn’t perfectly synced with marlin.

Thanks guys for the explanations, right now it’s a little difficult for me not knowing what’s ‘normal’ and what isn’t. Little quirks are much easier to deal with when expected, then they become charming little quirks.

I don’t personally use any of the software or controller under consideration here, so this is complete conjecture, but…

I’ve seen forum posts stating that the dual end stop firmware won’t go negative until the machine has been homed (or something to that effect). Does this apply to the Z axis as well? Is the dual endstop firmware in use here?

Looking at the G-code, the X and Y movements never go negative, so they wouldn’t violate the “no negative values” rule, but the Z does, and it sounds like the Z axis will move up to positive values, but not down to negative.

It doesn’t affect Z. I think you’ve also got it backwards, it won’t go negative after it is homed.

Position the end mill to your starting point

Send a G92 from Repetier

Click Print

That seems to have done the trick, I’d send a pic but it seems I may have the MPCNC working so my camera decided to have a hissy fit, won’t download over WiFi and I don’t have the right cable to hook it up.

Gilda was right, If it ain’t one thing it’s another. ![]()

Gotta find the camera book, can’t hurt to uninstall/reinstall the software I guess.