So I am cutting 1/4" MDF to create templates for my router table and I am running into an issue with the cuts. The finished piece will have little bumps in the cut almost like the gantry is wobbling when cutting but it seems to be rigid. I am running at the same feeds and speeds as I have in the past and didn’t have issues then. It seems to be worse on curves but I have noticed it occurring on straight lines as well. These “bumps” as not huge either, you notice them by running a finger along the edge of the piece or if you really look.

Are you doing a finishing pass?

Always a good idea to make sure the pulleys aren’t slipping due to loose grub screws.

Photos may be helpful as well.

No I haven’t been doing a finishing pass, not to be ignorant but how does that work/ help?

Unfortunately, I got rid of the piece (mistakes make nice kindling in the fireplace)

So most of a cut, the tool is removing a bunch of material. The bit cuts into the marerial with the amount of material that you want it to remove every pass. You choose this amount based on getting the job done in a reasonable amount of time.

The problem is that this puts lots of force back on the tool, and the machine then deflects, resulting in some inaccuracy. In addition, each pass steps down into the cut, so what you can’t cut in a single pass will have visible lines.

A finishing pass removes only a small amount of material, and usually full depth. The small cut amount means less force back to the machine, so less deflection, more accuracy. Plus a full depth cut, so no lines along the edge.

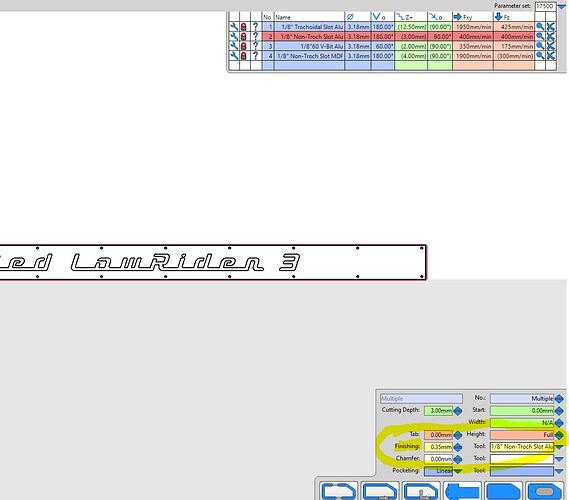

Further to @SupraGuy’s thorough explanation about “why”, for the “how”, you set the finishing pass in your CAM software. For EstlCAM, when it asks you for total DOC, there is also a section in that area to define the finishing pass:

With a 1/8" (3.17mm) bit, I use 0.35mm , or about 10% of the bit diameter.