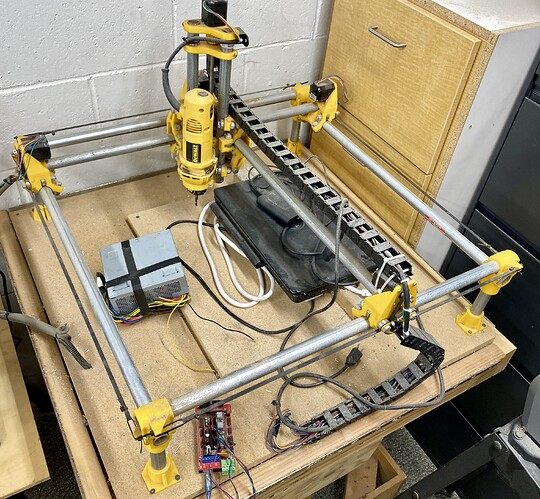

I bought a completed router that wired fine when I purchased it. During shipping by me the power supply feel out of place and the two wires came out of place, also 3 ribbons came out of place. Some of the wiring is obvious but not everything. If I can get a wiring schematic I should be able to trouble shoot my issues east enough. Thx for any help SS it’s been sitting for a year

Welcome to our forum. Given your description, I’m guessing you have a spindle with a VFD, not a router. Wiring will vary somewhat between models and manufacturers. Please provide us the model and any other identifying features. If you purchased it new online, a link would be helpful. Pictures would be helpful, though as a new poster you may be limited to just one or two pictures.

So, I was wrong about the help you are seeking. You want to reconnect the cables to MPCNC machine.

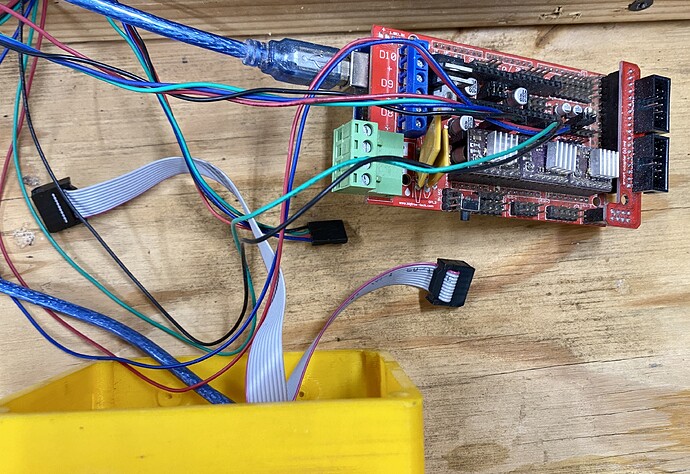

These pictures are really helpful. What you have is an older machine (I think it is a Burly) being run by a Ramps board and using a computer power supply for the power. It only has three stepper drivers so it will be wired in series.

First let’s address power. You need to connect power to the green connector. It needs to be connected in two places as described in this diagram:

You may have to use a multimeter to figure out what wires from the power supply to use. You can use a jumpers and only bring in one pair of wires from the power supply. Or you can pull two pairs of wires from the power supply.

For dealing with the rest of the cables, I caution you to never change a connection while the board is powered. Ramps boards are fragile compared to newer control boards, so it is pretty easy for a wiring mistake to blow the voltage regulator on the Mega board, or burn out a needed pin. Mega are only $20 USD, but it is a hassle.

Second, the gray cables are the display. The obviously plug in to the sockets on the far left of your picture. I cannot say which cable goes in which plug (and in what orientation), but you will not hurt your board by trying configurations until the display works. Again, always power down the board. Frist, try the two orientations where the plugs are matched (both plugs have the red strip on the left for example). There are only six combinations in total.

Finally, the four wire connnector needs to be plugged into the third stepper driver:

I’m not sure of the orientation. Make it match the plug to its left first. If the orientation is wrong, the axis will move backwards. If so, just flip the connection (with the power off).

Thank you so much for your help.

Now that I think about it, you may not need power to both power connections. I think the 5A connection is just for the heated bed, which you obviously won’t be using for a CNC. Try connecting to just the 11A connection and see what happens.

FYI: The Burly like you have was my first CNC machine, and I used the same rotary tool for cutting. It worked well. I upgraded that machine to a Primo, salvaging a good many of the parts.

WOW, that looks just like my first CNC. Even the table looks similar.

Mine had the miniRambo controller though.