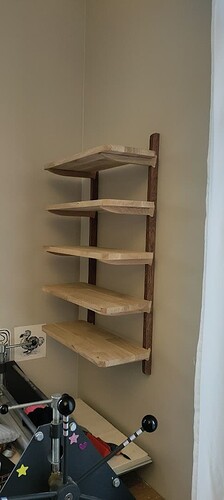

My wife comissioned some shelves for the new office to display some pottery

After a bit of searching and inspiration, I settled on this design

These will be cut out of oak flooring I have laying around

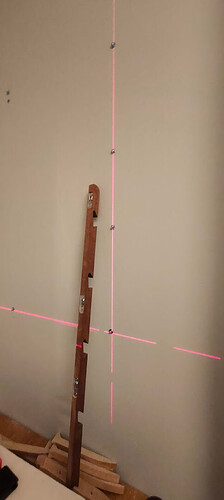

First, I cut an mft-style fixture plate to ensure the stock is aligned with the machine

Then after some refining to fit two pieces in the width of a plank, and burning the router, I cut the contours 18-19mm deep

The flooring is 23mm thick and has 5mm deep grooves on the underside for glue

I need to purge these grooves and release the parts, so into the planner it goes…

The LR3 had a hard time cutting the back pieces, so the parts don’t really fit ![]()

I 3d printed a router template and gave every slot a quick cleanup with a copying bit

The fit was not perfect but much better after this…

Sanded everything, tainted the back pieces dark and gave everything a quick coat of varnish

Now I need to make the shelves themselves and attach the back struts to the wall, but it will have to wait a couple weeks ![]()