Notice anything?

How’s the performance between your previous LR2 and the LR3?

I still have my LR2 for full sheet work. My LR3 is a much smaller machine, mainly used to evaluate the design. I think the LR3 is a much better design than the LR2. I did heavily mod my LR2 to deal with the weaknesses I was seeing in my use case.

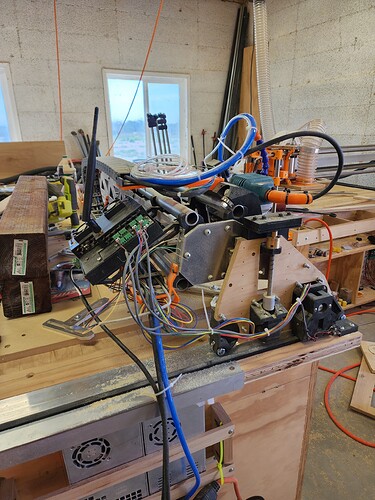

In anticipation of replacing my LR2 with a full sheet LR3 with a 2.2kW spindle, I have begun modding the base design for a new 5.5’ x 10’ table. My Y-axis belts are no longer suspended in air, but are each captured in a GT2 “rail”. My gantry is now comprised of 4 tubes in a trapezoidal arrangement with new braces and new XZ plates that support all 4 tubes. I am currently evaluating the use of Oldham couplings on the Z-axis to eliminate concentric motion in 3D milling. I have more mods to do but life has slowed my progress.

Those mods sound cool, look forward to pics if/when you’re comfortable sharing them.

So many questions

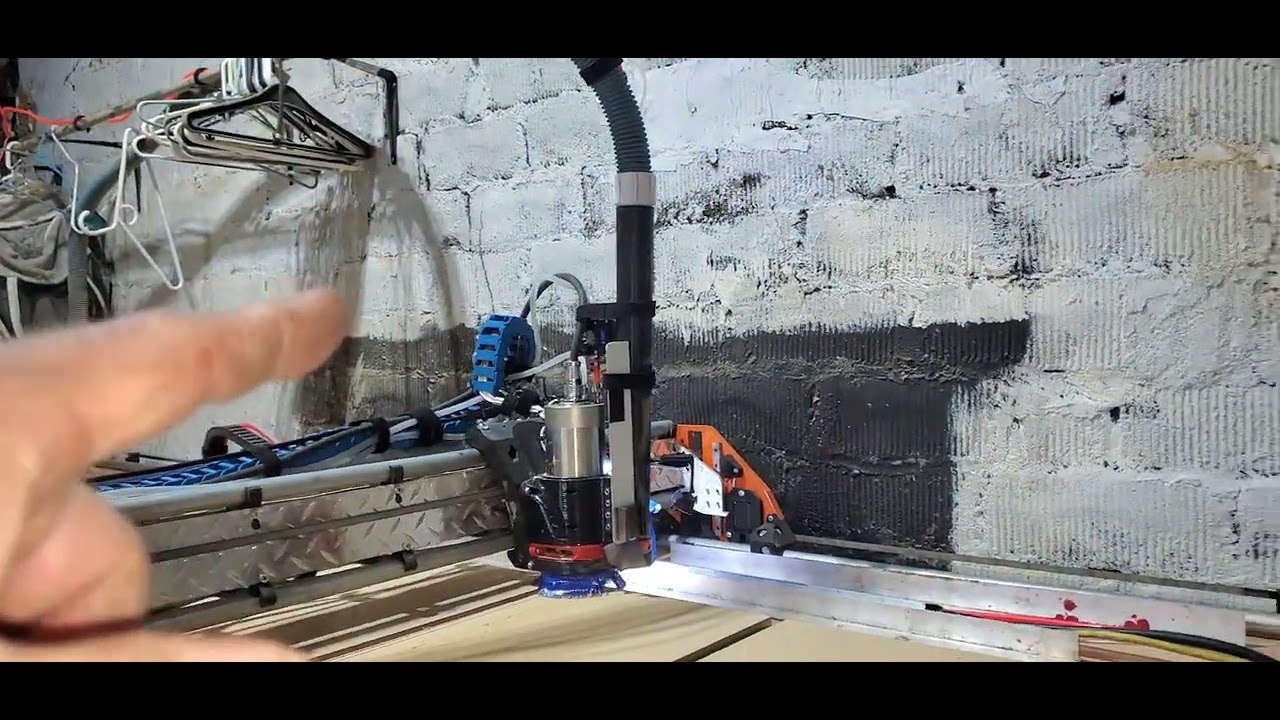

Yeah, I’ve also got at least two… ![]()

You’re awesome. I was inspired by your LR2.

I’ll share some images tomorrow.

I wanted the stability at high and low Z, so decided not to go down the LR2, route. Instead I have a 5x10 (just over 4x8 cutting capacity) primo in NEMA 23s, albeit not standard and similar to what you have done with the LR3.

My reason for doing so was instead of having the weight on one side of the gantry, why not have it in the middle.

Your gantry looks very rigid. Are the Y-axis rails DIY or purchased?

It is really rigid, or at least feels it to me. Purchased 25mm SBR linear rails for the Y axis

hey bud im using one of these as well on a 4x8 built but I’m getting a lot of deflection how did you avoid this? i see your using the same mount I’m using as well