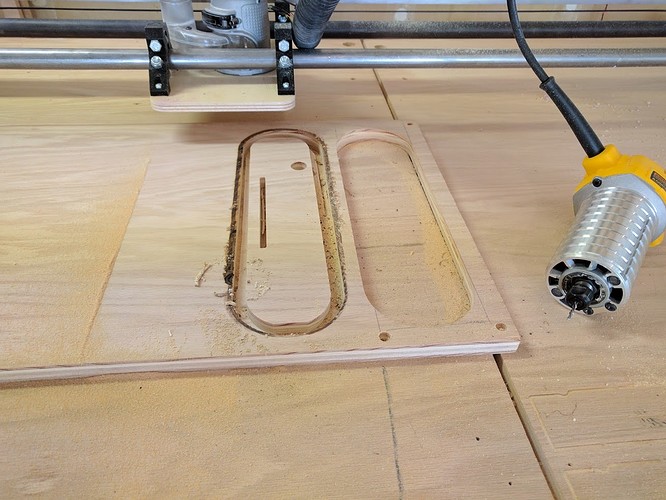

Make sure you keep an eye on your routers!!! Pretty sure the shop vac blew out the fire. Not sure why it went that low. There should have been a centimeter of clearance. The collet made the bulk of the burn.

Whoa. Are the other cuts burnt too? Or are those shadows?

Glad you and your barn are ok.

Oh damn, how scary is that to see. Looks like it kept going for a while.

Nope, the other cuts are fine. It was still happily cutting, into the table, the other parts. You can see the line it cut, full depth in 3/4" plywood off the board. Not sure what that cut was supposed to be.

Okay, so not to self and everyone else. Make sure your collet holder doesn’t hang lower than the rest of the machine. I know in theory the bit can cause a fire too, but looking closer at the damage, most of the burnt wood was just friction from the collet holder. The bit was still cutting without issues. I was trying to get that extra couple millimeters of cut depth, should have just put a longer end mill in. I have them…

Dang man. Lesson learned I guess. Glad you and the house are ok!

Neil

You’ve convinced me. I bought a smoke alarm and a fire extinguisher.

I blame you, Barry. This is somehow your fault

I was organizing the garage while it cut, and I was just hanging the smoke alarm when I smelled the smoke. No alarm went off though. Turns out, the CAM was trying to go to -31.5mm in the Z direction. I had the part cut itself out after the pocket, so I had it go to a depth of 18.5mm, but start at 13mm. Apparently, that means it will go 31.5mm down. Ooops.

Yea, I don’t let the collet holder stick below the plywood anymore. At least that way, it’s the whole assembly dragging, not the large flat spiny part!

Also, you don’t need to cut the blade slot for your table saw insert. Just slide your fence over half the insert and raise the blade up through it. Makes it a zero clearance insert so you don’t get as much tearout. Make sure the blade isn’t going to come up into the fence first! I may or may not have killed a sacrificial fence face once…

Note to self… always double check Barry and Jeffeb3’s work before you turn on the machine…

I had that too… I printed this fan that hooks on to the bottom of the router and blows the chips away. Works awesome. Except… as the bit cuts the collet heats up and eventually melts the fan which explodes and wedges down in your cut jamming up the motion control… and it my case for some reason popped loose the top mount and the whole Z assembly fell down onto the table and sat there wiggling around and catching the wood chips on fire, cutting a hole in the table, and dropping burning chips down onto a wooden tool box which also caught fire… All of this in the time it took to walk inside, pull up the dxf I was working on and look at a couple measurements and walk back to the garage. Maybe 5 minutes. Thankfully I caught it all before it really got going. Imagine my shock walking into a garage filled with thick smoke. Everythingmy fault and once reassembled the MPCNC is 100% fine. Used it a bunch since then.

Lessons: 1. Don’t leave machines alone.

2. Don’t use PLA for warm high speed parts.

3. Check that things are tight before using.