Hi, I just finished my MPCNC Primo and now of course I want to complicate my life by adding the laser diode from my small Chinese laser engraver.

I am pretty new to this whole CNC also DIY electronics and things like that so that is why I am asking for help with this.

Can you convert a Vigotec VG-L7 20W Laser Engraving Machine that is still functional to a MPCNC operated Laser engraver, and most importantly how to do this?

Welcome to the forum!

I was wondering exactly what you’re trying to achieve: If you have an operable Laser machine, I would continue to use it as built. That looks like a nice, portable machine.

There is not likely to be any real advantage to installing a laser module on the Primo, except to have a more easily adjusted Z height or if you need a larger work area.

What was your goal when you built the Primo? (other than the fun of building it).

I started with the Primo, then built a medium LR3, then got a small laser engraver, and finally built my little LR3. It’s very easy to get started, but once you’re hooked…

Mike

Thanks for the welcome.

The reason I am trying to add the laser to the MPCNC is to increase its size.

I built the laser on a table of 1mx1.25m so this gives me quite a large area of operation compared to the 19cmx30cm of the original setup of the laser.

Also I want to use the MPCNC for as many things as possible (at the moment I have a rotary tool, pen, brush and a foam cutting pen) as I am trying to save space and money.

Later I will probably try to add a plasma cutter if I deem it is in any way feasible but that will be another post in a far away future.

That depends on the laser itself. If you already have the MPCNC built then you can add the laser and hopefully it’s power/driver to it, that is all you will use of the old machine.

You will need to add more details / pictures to get a better idea of what is there.

The easiest way to do this is start making projects with what you have. Making a machine that can do everything is just a pile of tools. Do you need all of that right now? The more fluent you are with using a CNC the easier it is to do other things with it.

For a specific example, the only reason to add a diode laser is to engrave typically. The CNC can cut far faster with a endmill. You want a giant engraver, or can you cut your parts and just engrave/etch your logo with your purpose built laser?

We are all for one machine to do it all, but if you already have two, not all that much sense in combining them.

Thanks for the reply. I will add photos tomorrow (I am at work now ![]() ).

).

I still want to try as I had to engrave a 60x60cm board for my daughters dance props and there may be some other projects that will require more than 19x30cm that I can do with the actual setup.

Plus I like tinkering but not without a bit of safety measures like asking for advice at the minimum. I don’t want to lose my toys.

As long as that is part of your goal…that is perfect.

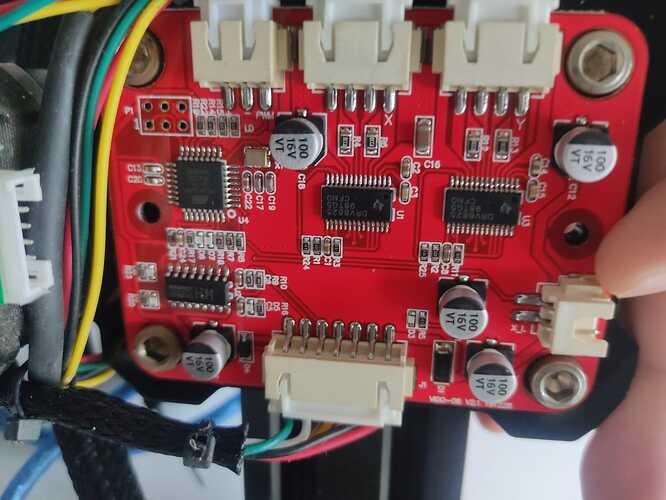

This is my small engraver from which I am trying to add the laser to the MPCNC.

Do I need to get the pcb from it in order to operate the laser module or can I connect it to the SKR Pro v1.2 and control it from the MPCNC marlin software? Do I need a separate power supply for it (how to connect it)? If it’s just the module that needs to be taken from it I will probably buy a more powerful one later, but I want to try with what I already have first.