For more on use of the Jackpot controller with a LowRider v3 CNC, watch these other short videos:

For more on squaring (for either a Jackpot or a Marlin based board), and how software-based “pull off” is done on Marlin-based controller boards, watch this video:

Buy the Jackpot controller board from V1 Engineering here:

Buy the Tiny Touchplate (for probing) from V1 Engineering here:

Download the printable “magnetic tip for touch plate wire” (v1.0) for CNC machines here:

https://www.printables.com/model/446174-for-cnc-machines-magnetic-tip-for-touch-plate-wire

V1E’s documentation for the Jackpot board is available here:

https://docs.v1e.com/electronics/jackpot/

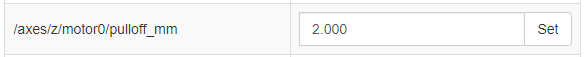

…and if you search that page for instances of the word “probe” you will see several mentions. Among them is the fact that a probe routine is present in the “Lowrider Starting Gcode” — which by the way, if you have probing scripted in that way, the gcode outputted by whichever CAM software you use (ESTLcam etc) will account for probing as part of each job. The “Lowrider Starting Gcode” is below, and it can be used for creating your own Probe Macro button on the Jackpot. Below, I have added “remarks” (commented out so they don’t get acted on) to explain what the result of each gcode command would be:

G21 ; (assume part programs are Metric, as opposed to Imperial, which would have been G20.)

G90 ; (absolute positioning, as opposed to incremental, which would have been G91.)

G94 ; (interpret feed commands as inches/min or mm/min for linear moves.)

G92 X0 Y0 ; (set current position to values specified — and there are other code options for this.)

M0 (MSG Attach probe) ; (issue a message to operator to attach probe.)

G38.2 Z-80 F200 P0.5 ; (probe down to get thickness, allowing 80mm travel, speed 200, plate thickness 0.5 mm.)

G1 Z10 F900 ; (move upward in Z axis by 10mm at a speed of 900)

M0 (MSG Remove probe) ; (issue a message to operator to remove probe.)

M62 P1 (If used start spindle pin27 )

For clarity and convenience, I’m using my Jackpot with hard limits enabled and soft limits enabled, and my table size included in my config.yaml file, and the following is the exact script I’m using for my Probe macro (except I have the M0 commands commented out by starting those lines with a semi-colon, and I also don’t use the last line for spindle start):

G21 (MSG G21: Metric mode)

G90 (MSG G90: Switching to absolute positioning)

G94 (MSG G94: Feed = per minute)

G92 X0 Y0 (MSG G92: Setting current XY position as workspace origin 0,0)

M0 (MSG Attach probe)

G38.2 G91 Z-124.9 F400 (MSG G38.2: Fast probing to material)

G1 Z5 F400 (MSG G1 move Z up by 5mm, speed 400)

G38.2 G91 Z-6 F100 P0.34 (MSG G38.2: Slow probing to material. Plate thickness: 0.34)

G90 (MSG G90: Switching to absolute positioning)

G1 Z30 F900 (MSG G1: go to Z30, speed 900)

M0 (MSG Remove probe)

M62 P1 (If used start spindle pin27)

A huge “shout out” and thank you to Bart Dring & Mitch Bradley & Michael Melancon of the Fluid NC dev team, and also to Ryan Zeller @vicious1 over at V1 Engineering Inc, and all the helpful crew at the V1E forum!