It’s a decent use when you actually have an inside corner to deal with, but Thales Theorem is actually much more useful than that.

It can be used to create a perfect 90º cut line off of any reference line, as long as you have a compass, or other reasonable ability to draw a circle.

I actually used this method when we built a metal building shop for my dad because whoever poured the slab obviously never heard of squaring as a thing people do… and it was like 8" off on a 30’ slab…

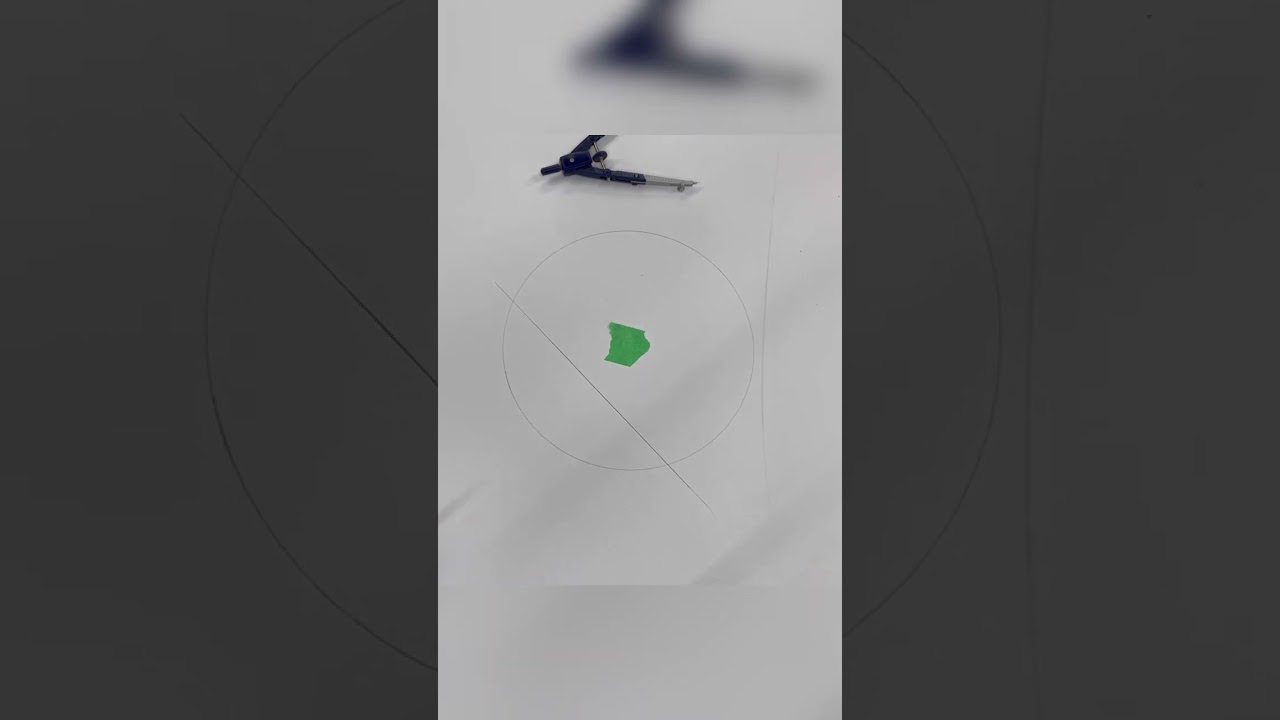

Here’s a decent explanation of the principal.

Lot’s of ways to apply it to woodworking when you don’t have a tool for squaring, or don’t have a trustworthy reference side.

I love that! I’ve known about the theorem of Thales since high school geometry class 40+ years ago but I didn’t know it had ever been turned into a practical work shop tool. Awesome! I might have to make one for myself.

And here’s an example he gave on a different platform for a way to use it:

Similar to what he did, I used the method with a piece of string and a nail to make a circle that intersected at the right place on the side edge of the concrete so I lay out a square line across the back

Hmm I wonder if this could be used to simplify Y squaring on a Lowrider. Although I would imagine measuring diagonals will always be the most accurate.

I’m seriously curious as to what the real world use for that is, where could it possibly come in handy between a large framing square, and the 3,4,5 rule measured on a tape measure at any scale you want?

For those unaware - a triangle with a base of 3, and perpendicular of 4, has a hypotonuse of 5.

It’s infinitely scalable so it works whether you are checking the square of a house or an LR4, and like the Thales square, you can see instantly how far you are out and what needs to move.

So, is the argument why use geometry, when you can use geometry instead?? ![]()

It is certainly not the best tool in a lot of places, but I gave a least one case above where I used it, and it was the best thing I had available.

It simply required some string and chalk to create a perfectly square layout in less than 5 minutes.

For some, scaling with a shape is much easier to get right than doing the math to scale the 3-4-5… sounds crazy, but I have met people that can struggle with that immediately when you start talking numbers, and shapes are much easier for them to remember.

It’s only infinitely scalable if you can find an infinite length tape measure.

I can find a 40ft string a lot faster than I can find a 40ft tape measure in a pinch.

I wouldn’t call it a waste to at least just understand these things. You never know when they can come in handy.

You see, that’s where my understandascope falls down, I keep a 30m (100ft) tape in my car! ![]()

Doing it that way is an absolute measurement, too, so it’s limited by the accuracy of the measuring device. The other method is a relative measurement so is inherently accurate.

It’s probably splitting hairs in most cases now that we have modern measuring devices, but I checked all my tape measures vs class 1 steel rule (better than 0.2mm over 1m) and all of them were out by some degree. Most of them weren’t accurate at zero by 0.5-1mm but a couple had the scale be wrong, too. Those are mostly Stanley Fat Max or similar tape measures so I could easily see cheaper ones being more out.

If I had a dollar for every bricklayer who insisted on using his elcheapo “fibreglass” tape to check his work for square…

Some of them can easily stretch 100mm in 10 metres! (I carry a steel one! ![]() )

)

In the second video, it shows you how to find the line that is square to the centerline. IMHO, that is the benefit of the Thales vs 3-4-5. The 3-4-5 is better at checking for square, but worse at finding the square line. Thales doesn’t seem as useful for checking for square.

Exactly, and that was my use for it.

It also let me do so at an exact spot.

It’s just not that easy to do so with the 3-4-5 rule if all you have is a tape measure.

I can tell you if it IS square with it easily, but not create a perpendicular line through an exact point.