HI I am working on a DIY CNC table conversion to laser. using a Neje A40640 dual laser module. Using a Arduino Mega 2560 with GRBP Mega, What are the changes I need to Make in the Config.h file. I know there are some in the Uno version for the enable spindle and and for Pin output. I hope there is help with this.

I just saw one of those A40640 LED units advertised as 80W that can slice 20 mm of plywood for sale and it looked like a deal too good to be true. I have a 60W CO2 tube and it struggles to slice 1/4". It would be great to get info on its quality and real power output. Please share additional information as you can.

I do cut 5mm in birch plywood in 1 pass at 120mm/min 100% power with that laser and air assist.

Haven’t tryed bigget thickness yet, but i’m quite confident on 10mm in 2 passes.

A40640 has 15W of optical power

do you know the wavelength of light it emits?

That statement about the 80 W is bogus, the module has two 5 W diode lasers directed as a single beam. It does not have the power you CO2 laser has sorry.

I have it mounted on an Ortur base with air assist it will cut thin plywood.

Uploading: DSCN5123.JPG…

General Specification

Model:NEJE A40640 Module

Heatsink Material:Aircraft Aluminum + Brass Shell

Luminous Color:Blue

Section Size:40mm x 40mm

Cooling Mode:Temperature sensor intelligent control + 10000 rpm 40mm cooling fan

Dimension:60 * 40 * 40mm

Adapter Plug:5.5 2.1 port

Can Engrave:MDF/Balsa/Paper/Wood/Fabric/Plastic/Leather/Plywood/Foam Paper/Anodized Aluminum

Technical Parameters:

Optical power output:10W

Wavelength:445-450nm

Beam Shape:Dot (Focusable)

Working Voltage:DC 12V

TTL&PWM Modulation:YES, Compatible with Both TTL & PWM Modulation

Input Voltage:DC12V 3-4A

PWM/TTL Input:DC3.3V-12V

Input Interface:PH2.0-4Pin (+,-, PWM/TTL, Temperature), 3Pin (+,-, PWM/TTL) , 2Pin+2Pin (+,-) + (PWM/TTL,-)

NOTE:Temperature interface can be disconnected,NEJE provides text instructions for temperature acquisition on the wiki.

Drive Mode:External ACC

Safe temperature range:<60 ℃

Module weight:204g ( The lighter the weight, the smaller the moving inertia, the better the performance )

thanks for the info. I don’t know why they would state it is 80W… Can you adjust the beam focal distance?

There is a focus distance you set the body to surface no turning of a lens like others.

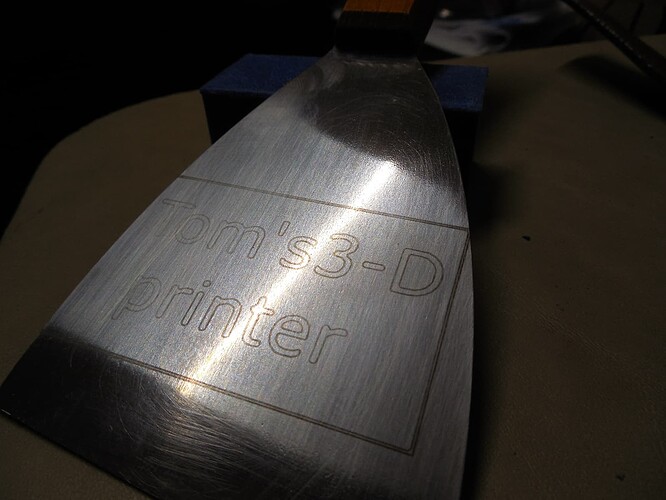

You can see YouTube videos of guys cutting on a slope to see where the true focus distance is. the look for the narrowest cut shape for the distance, it has a square laser dot not oblong like single beam lasers have. Attached is etching with mustard on a paint scraper, lines seem to have the same thickness in both directions.

What is this about mustard?

Mustard(condiment) can be use to engrave stainless steel.

You can see it in action in the video starting at 11:20

Yes sir that is the video I watched and it works, there may be other methods too.

It’s probably 80W input.

I need to try mustard with the laser.

Careful, might make mustard gas!

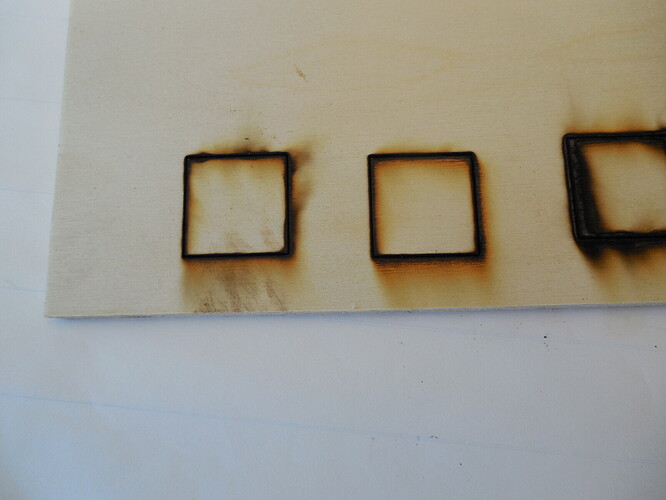

Other sample of cut in 3mm plywood with that Neje with Marlin:

You can get very fine details, i really like that A40640.

what board are you loading Marlin on, have you done any gray scale or photo engraving with it???

I have just did a temporary hook up with one driver and motor, firing the laser.

https://drive.google.com/file/d/1Bk-JY3Zkpy3oAaRdJJEMzijuzlm8mIwe/view?usp=sharing

This is great. I like using mustard bottles to hold wood glue. But I don’t like mustard. Now I have a use for the mustard!

I’m using a SKR PRO 1.2.

Haven’t tried gray scale engraving yet. I had a 2nd daughter two month ago and i can’t find free time to play with my stuff now

Mine was marketed as 40W (haven’t actually measured this yet), and it gets over 50C on long cuts at 100%. From my experiences that lines up with about 30-40W heat for the HSF it came with. I haven’t read much about the 80W version since it’s become available. If it actaully does draw 80W, it probably won’t last long even if they double the size of HSF on it. At that level of thermal flow (W/m^2), you need fancy watercooling to stay below 80C.

@acourtjester you mentioned poor cutting performance… it may could just be the kind of wood you’re using. I found poor cutting performance most often has to do with the adhesive, and the grade of the wood used in manufacturing the sheets. Many of the cheaper (overseas made) sheets I have seen lately come with a pink colored adhesive; it appears similar in color to old school toluene+spirits+xylene based contact adhesives I’ve seen (pink matric… not the “glitter” that various brands add to their adhesives to distinguish their products from others). You know it’s the pink stuff when you gag after cutting it, lol. To make matters worse these lower grade sheets have larger voids, which means you get some thick pools of glue to cut through. Cutting through those areas can sometimes require a ridiculous amount of passes… after a couple passes when the kerf is coated, the laser will barely cut anything and you’re better off with a razor/saw to finish it if you can.

OTOH, I have had lots of success with the “sande plywood” found at my local orange big box stores. It comes in 1/4 and 1/2 thicknesses, and uses a US EPA mandated soy based adhesive that the laser seems to have no problems burning through (it’s colorless). The stuff is also meant for projects where the ends are finished; thus it has minimal if any voids to worry about. The 1/4" cuts great 1-pass 180mm/s with air assist… I’ve literally had every single pc drop right out when lifting stock after the job (not even a hair requiring a razor to finish). This makes the 1/4 my favorite workhorse material in general… lots of structural strength with little time. The 1/2" parts will drop right out about 50% of the time with 2-passes… the occasional super hard knot or sap vein sometimes leaves areas that need a razor to finish. So 1/2 isn’t as easy to work as 1/4, but still I think within range for with a Neje 40W occasional projects that need a lot more strength.

Back OT… I posted my old configs from when I was rockin’ ramps+grbl (a Primo with dual endstops and stepsticks). Thing is, my setup was a bit unorthodox, since the ramps I was using had a burned out hotend output. So I had to remap the spindle enable to another pin (hence the defaults and cpu_map modifications). Either way, maybe it will help guide you to a working config.

Cheers,

Kev

GRBLrampsMPCNCdualEndstops.zip (23.5 KB)