Thanks for your assistance. I did change the cutout in the part and almost doubled the size of the rectangular…i was able to manage to mount it and it will be ok for testing.

Regarding slicer settings: we use 3d printers for automotive clients and their prototype parts and i am aware of the possibilities of holecompensation…the part which came with the used lr3 was broken the same way and the dimensions were correct. i will try to make some pictures…but after checking ryans instruction manual, i did understand correctly how to mount the belt (according to the pics online here)

I am now able to do a test run i just need to download estlcam, but i am a little worried, that the used lr3 was a bad buy? we will see…

thanks so far for your kind help…

armin

A little frustrating update: i was able to download estlcam and get contact to the cncshield arduino…

i was also able to program the arduiono but the motors are silent, they should , if the pcb would be working correctly, make a little noise and should not move…so it seems the pcb is defect…

even the arudion tells me it is working on estlcam software…

the seller has disappeared and ghosts me…now i know why ![]()

i will now have to buy new controllers which will be able to handle my planned upgrade…

What stepper drivers does the cncshield have?

The cncshoeld goes on the Arduino, and the stepper drivers go on the shield. Might be those are NG. Also worth checking are things like stop switch inputs.

I’m not sure I’d jump to the conclusion your board is defective right away. It could be but there might be some more troubleshooting to be done.

You could buy a new controller and still have issues if it’s configuration related not hardware.

Pictures are really useful if you want help - I don’t know what your familiarity with arduino and electronics is so it might be obvious from a picture that something doesn’t look right,

the stop switches are all cut off from the previous owner?

Sorry, I’m not clear what you mean.

We can’t really help without pictures, there are only a few users here who use a CNC Shield. One of them is myself, but without pictures it’s pretty hard.

Remember that you have buyer’s protection in the EU even when buying things privately, if it was not explicitly excluded from the sale (which not a lot of people do). Most of the wordings on ebay are also not legally binding. So if push comes to shove, you can most likely sue.

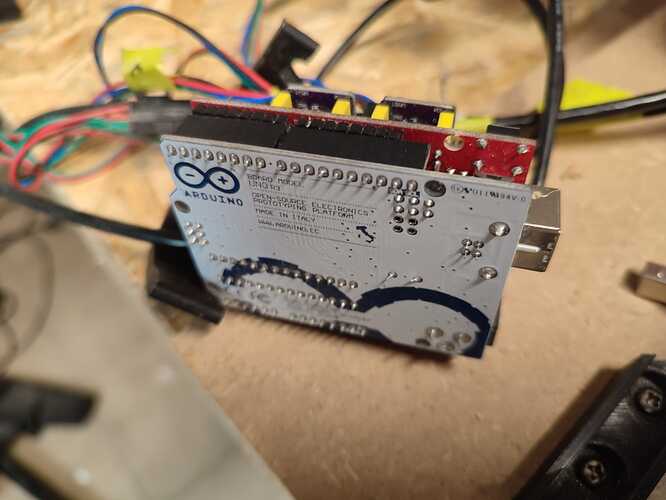

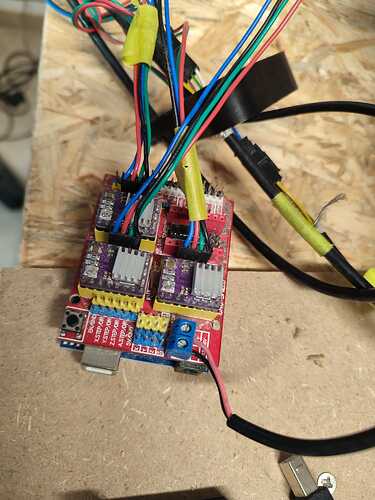

Hi Philip, i hope the pic will help.

i have the current status after rebooting and starting all over again this morning: Motors are not movable and i can hear a sound , so the motors seem to get power somehow…but i am not able to move the motors in any directions…

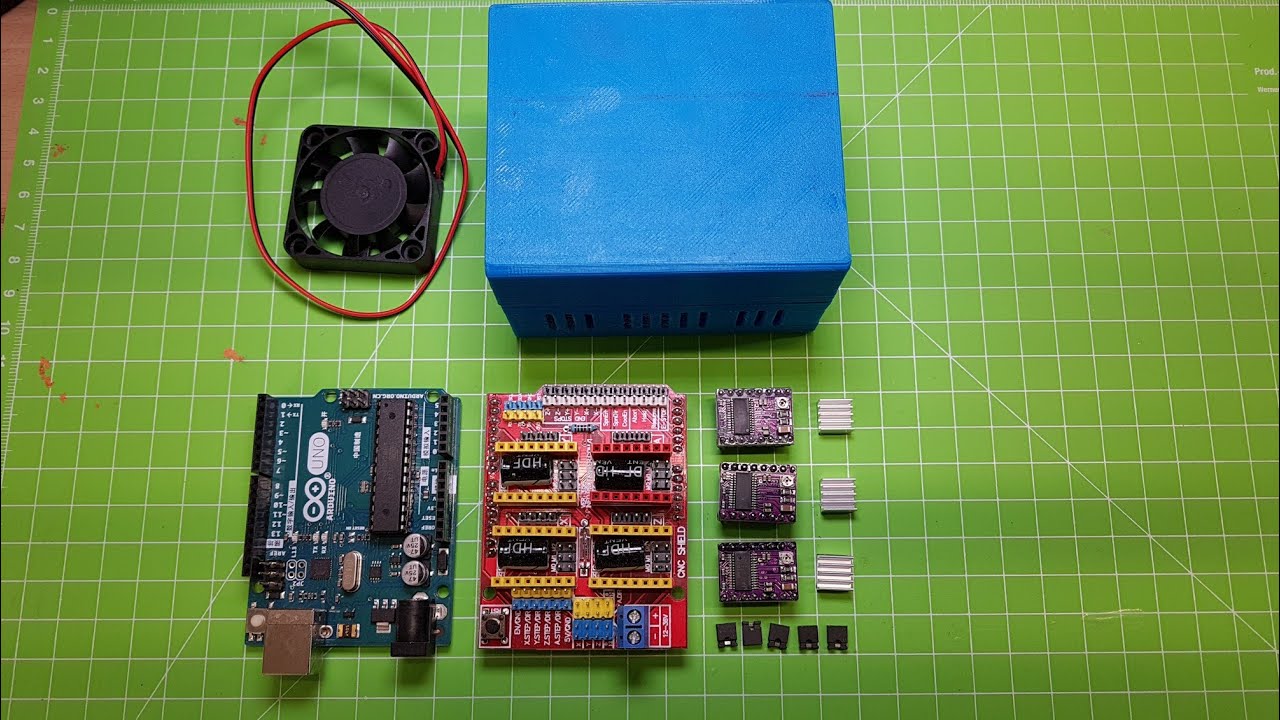

Oh, that’s the very basic one with only three drivers so you have to wire steppers in parallel/serial. There are plently of options for failure.

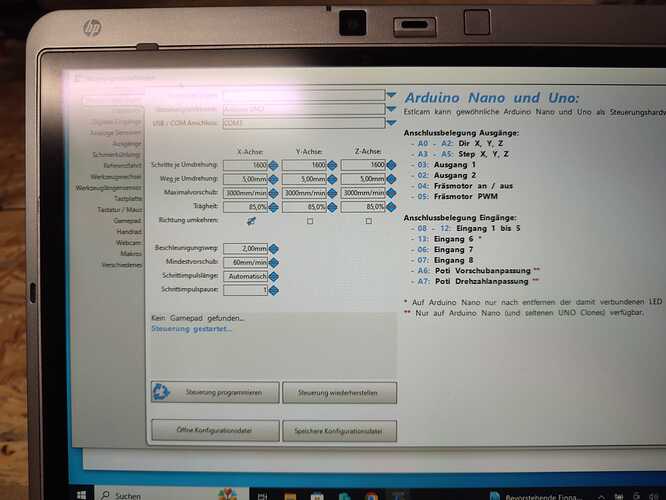

First of all: The board needs to be plugged in for Estlcam to control it. Secondly, those basic settings are not going to work. There is a video of Uncle Phil (that is now pretty old, but it covers exactly what you need) that you should watch. It explains everything you need to know about your board:

Hi Philipp, thanks for the input…i did contact the seller and he finally responded…

I made a mistake with not using grbl setup , i used arduino uno…after changing that, the motors run!!!

YEAH…

No , problems on one z axis arise.i had to change a printed part and i may need to check the manual again, how to set up the z axis correctly…

I may ask again…

What really bugs me, i have asked the seller for a screenshot of his settings in estlcam, but he never sent it…now, he provided it…could have saved us loads of time…

so far so good ![]()

That sounds great! ![]()

Yes, i ordered the parts…hopefully they will arrive tomorrow…but pretty busy at the weekend with training and family…

i do have two tasks for the machine: 1 is smaller 30 - 60 mm plate size carbon (4 mm) and the bigger woodstuff, i will see how it works, i am still not confident :-/

If it works, i will invest in a lr4 and new and better electronics from timos werkstatt…

i will keep you busy and posted…

When dealing with carbon, you definitely need a water basin if you aren’t keen on getting lung cancer. You can also not just pour the water down the drain in the end! Carbon is no fun!

Yes, i know…i did alot of not really safe rc modeling carbon stuff unprotected…

i am aware of water basin…this is why i thought of building a primo for that purpose?

or do you think…lr4 for all usecases is better?

Yes. ![]()

hm.ok…so i will start printing next week ![]() i still have the vevor spindle here…the nema17 will be enough, correct?

i still have the vevor spindle here…the nema17 will be enough, correct?

Most definitely. ![]() My gantry is made out of 1400mm long, 32mm tube with 3mm walls. It’s really heavy and I drive Z with 2000mm/min.

My gantry is made out of 1400mm long, 32mm tube with 3mm walls. It’s really heavy and I drive Z with 2000mm/min.

good morning, my plan is to use the lr3 for practising…which milling cutter do you use for mpx hardwood? if i may ask…

PS: i just tested it and the spindlemotor is 65 mm, so it fits perfectly…

![]()

I buy everything from sortec.de, no surprises with their quality. I am using a 6mm 2- flute and some 3.175mm 2 and 1- flutes.