@AlexBondCat Good luck, post som pictures of your work

Today was the day and finally ended being very frustrated, this eve I finally had the time to start up the LR2 and oooohhhh !!! surprise, one of the stepper motors on the Y-axis is missing steps and I haven’t been able to sort it so could not get my Y plate CNC’d…but hey this things happen so I’ll get this sorted and then start doing some of the projects I have in mind.

But to do so I need some of your advice, can any of you gurus help me to find out whether is the motor or the driver, or maybe both that is failing?

Cheers,

You can swap the plug with another motor at the controller. Motors don’t really fail. They seem complicated but they are tough as nails, literally. I would guess wiring. It is very often the wiring.

I checked all the wiring and took it out of the protection sleeve to find out it was one of the dupont pins on the driver not being rightly plugged for some stupid reason, I replaced it with a JST connector which are the ones that should be on this Bigtree SKR Pro 1.2 board and it now works pefectly.

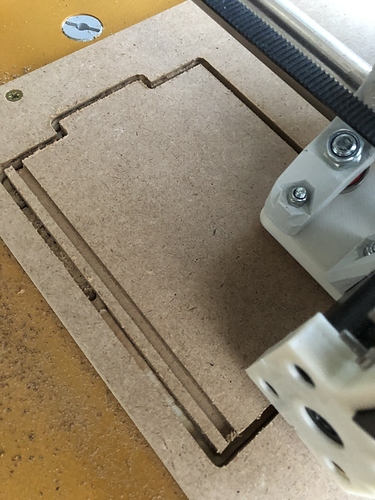

Did my first cut, missed to checked that the bit was low enough for a full cut on the MDF…my fault but seems to work great, now I’m off tot test 2 with the bit low enough to cut full length of the MDf board.

Will post pics later when finished…

Thanks @jeffeb3 for your unpayable help on this project.

Àlex

Glad you’re finally operating on all cylinders.

Got it rolling, but my bits are too short and trying to make them sit on the router low enough for a full length cut means having the bit way too out of the collet which turns to make too weak for 5 mm DOC on each pass and they keep breaking, I’ll have to get another 5-8mm spoil board to higher the cutting board so I can mount the bits as they should on router. Next table will have lower rails for the wheels so spoil board is closer to the router base.

I’ll report through the week as I get things sorted, but so far I’m happy to see it moving and cutting.

Àlex

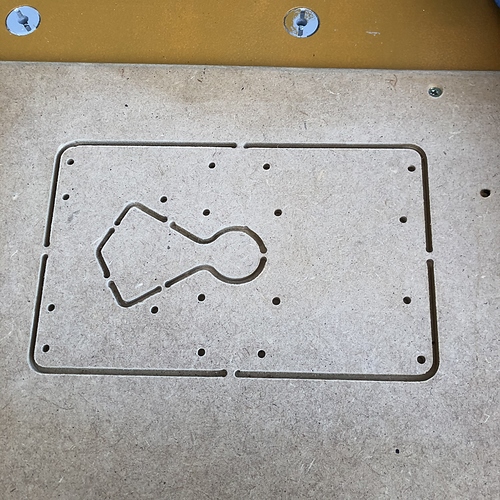

@Tsander here’s my first decent job…still needs some fine tuning but really happy with the result…I’m actually very impressed !!!

Finally went on a 2 flute bit, speed of 8mm/s, plunge of 2mm/s and DOC of 3,65mm and it worked without breaking the bit…I’m not too sure though if I have to keep router rpms at 22.000 or lower them…I’ve learnt the hard way that anything above that will break my bits on MDF.

Àlex

Looks good Alex…keep on going.

It is a great pleasure to have done a job thats is usefull.

You need to get some decent bits from CMT. I know it’s a bit expensive, but to a good job it needs a good tool

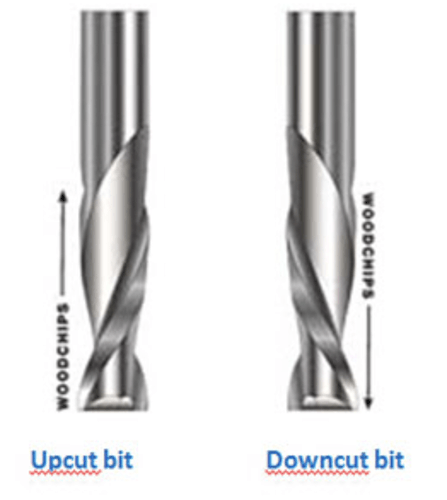

Hope this question is OKEY here since you are talking about upcut and downcut. I didn’t know that was a thing before this thread. I am not done with my LR2 build yet, so I’m just gathering information at this point.

Is this the only difference between upcut and downcut bits visually?

Also, I then noticed that I only got 4 flute downcut bits flat end mills. Are those good for plywood and wood in general?

@Tsander which size and depth of cut bits are you using? I only have 1 CMT bit at the moment and I’m not too sure if LR2 will keep up with it as it’s a 6mm.

And yes it is very satisfactory to see a job done and useful !!!

Cheers,

@dailybombs I didn’t know either before going into this new world of CNC…upcut bits chip out so there’s less risk to catch up fire due to friction and leave a very nice finish at the bottom end, downcut bits and more prone to catch up fire on hardwood and chips are more difficult to evacuate from your job, but will leave a very nice finish on the top surface while cutting.

I’ve only used upcut bits so far, maybe when I’m more comfortable with CNC works will try the downcut ones.

Hope it helped you !!! And now get your hands on and finish the LR2 and enjoy it !!!

Àlex

That is the only difference. The consequences may not be obvious though. I didn’t see any extra danger of fire, but pushing the chips down caused the bit to wander sometimes. Especially in right sides like plunging or drilling. It does leave a very good to finish though.

A 4 to flute is not ideal. With the speed of these routers and the speed of the machine, it will be getting pretty hot and not take very big bites.

Ah okey, thank you!

I will get some 2 flute end mills then. Thank you. Just ordered a 1/8" collet to my Katsu also. Waiting for it to arrive.

Aha!  Thanks for explaining!

Thanks for explaining!

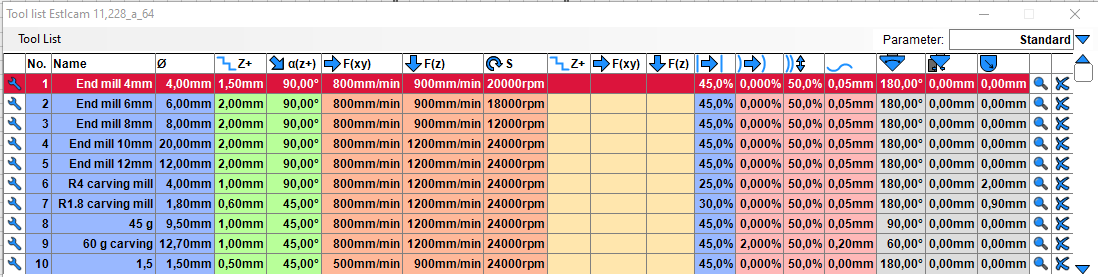

@AlexBondCat I am using 4-6-8-10 and 12 mm and ball nose bits upcutting CMT bits, no problem

@Tsander Tommy, what speeds are you using on different materials and DOC ? I’ve succesfully cut MDF at 3,6mm DOC and 8mm/s speed…2mm plunge…at 22.000rpm on the KATSU (Makita replica) router.

By the sound of the router sometimes it’s like it screams a bit, majorly when changing direction, should I slow down RPM’s ??? Or is it ok?

Cheers,

I haven’t had the time to really look at your sheet…will do it tonight, and thanks for it Tommy.

Btw I need some advice on joinery design for CNC…any tips or ideas on what works best ???

Cheers,

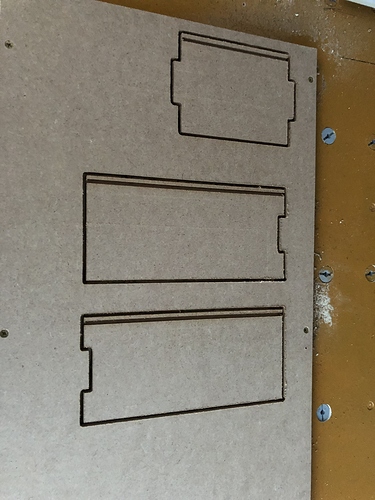

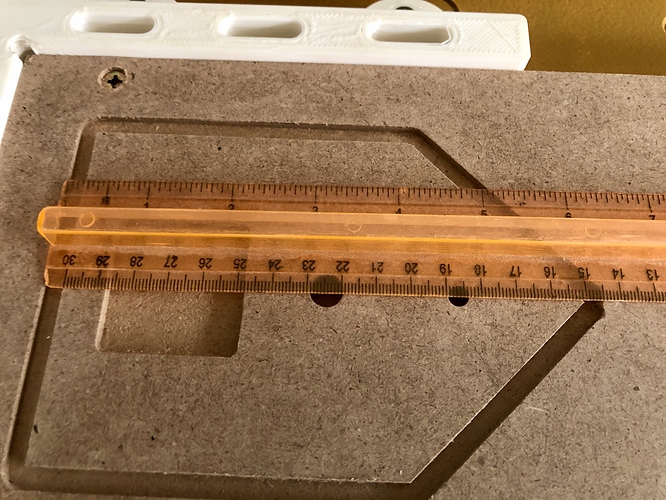

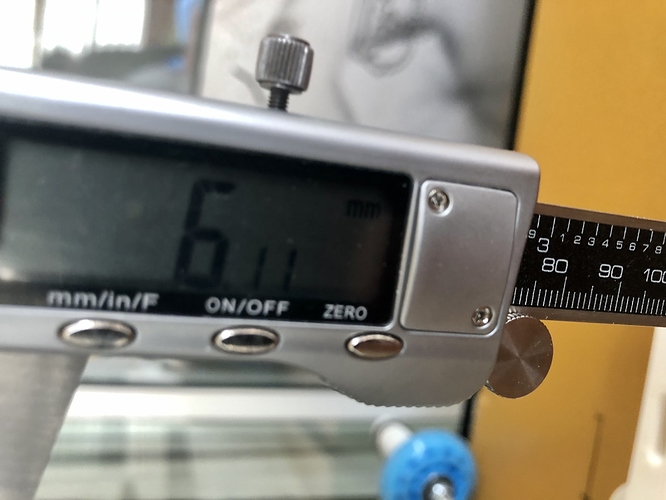

Followed your sheet parameters for the 6mm CMT single flute bit that I have and went for the squareness test I prepared…results are amazing, thanks @vicious1 for this nice engineering.

Here are the results…