Sounds like my neighborhood.

Take a look at how different these bits are. The ones from the v1 store don’t have a channel that chips get packed into like my amazon ones.

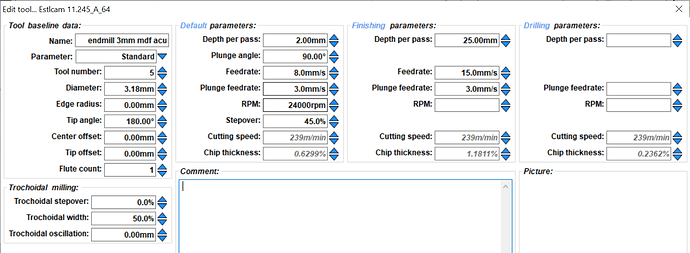

For the v1 1/8" endmill I updated my tool settings to this -

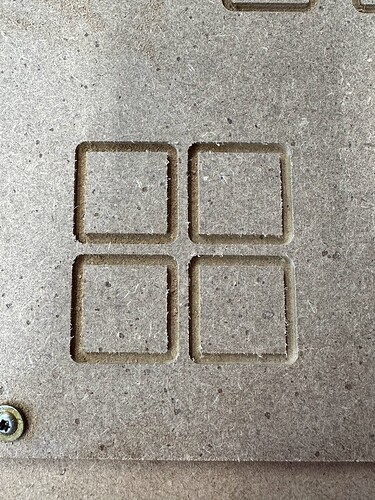

I ran my 4 square test. The x direction is ~25.4mm +/-0.01mm. The y direction is still ~25.52 +/-0.03mm. Possible error includes 1/not surfacing the spoil board 2/harbor freight calibers 3/not perfectly square 4/trying to measure mdf 5/something else?

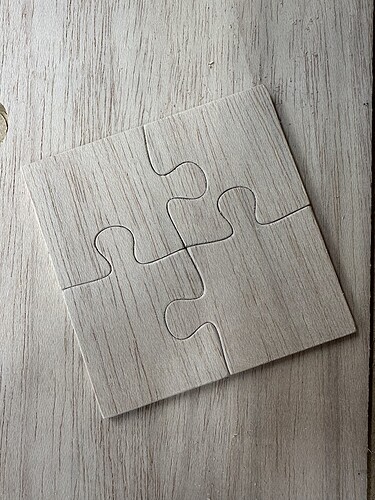

Then I tried the heart again and much better. I think I would have to build in an offset if using hardwood. This had to be put together with a mallet.

Probably could be a tad tighter on the bottom, but I am pretty happy with this now.

At this point I think re-doing the squaring will tighten that up.

Looks much better now though!

Tested square again and its within 1/32" over 700mm x 1300mm. I think that is square enough and shouldn’t affect a part 100mm x 100mm.

Could my Y belt not be tight enough or too tight?

Yeah that is great.

I don’t know.

Could that joint be so tight it is flexing the bottom out?

I think you are there. If you dial in the gap you need I bet the next one fits better. Too tight has it’s own issues.

A ruler test with a pen (G-Code Test Pattern Generator) along X and Y can tell you if you have:

- Backlash

- Nonuniform movement (unlikely but theoretically possible from eccentric pulley)

- Can also happen if your axis is not smooth and it has sticky spots

- Correct distance (steps/mm or belt stretch or defective belts)

It is possible that the belts are too tight and stretched, giving dimensional error, but the magnitude of the error is too large to ascribe to belt stretch alone.

If the size error shows up uniform across the entire length of Y, and not due to backlash or irregular movement then you could adjust steps per mm and nevermind the underlying cause.

Will try the ruler test at some point.

Adding a .25mm offset makes the piece go together really nice.

Wow, now that looks good!

I think 0.30mm offset is really good too. They are easier to get apart but still tight. I think I will try this out of hardwood tomorrow.

r

That’s really impressive. It looks a lot like a commercially produced puzzle with the small but consistent cut lines. Nice!

I agree those look perfect.

Remember any finish will make them tighter so you might want to give it a test run.

Nice! This is a challenge regarding both kerf width and margin of error.