Something a bit different here…

There’s a saying that goes: When you have a hammer in your hand, everything looks like a nail

Well just because you have a CNC doesn’t mean it’s Always the right tool

This is something I made with the LR3, and I maybe shouldn’t have in hindsight ![]()

This method has a few advantages, but in the end it was just a lot harder than a simple jigsaw and a scribe…

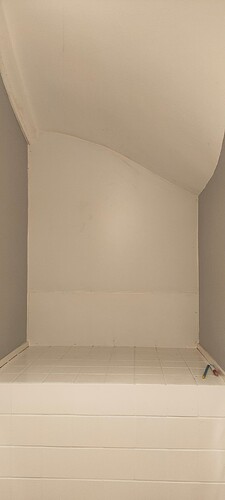

Heres the pitch: I wanted to install a few shelves in the water closet

There’s a kind of cavity with a window that has been blocked by a new construction, so I needed to make a sort of cover panel

The difficulty is that the ceiling is in fact the underside of a quarter-turn staircase, so it’s a pretty funky shape…

I started by laying out a few cleats with a laser level

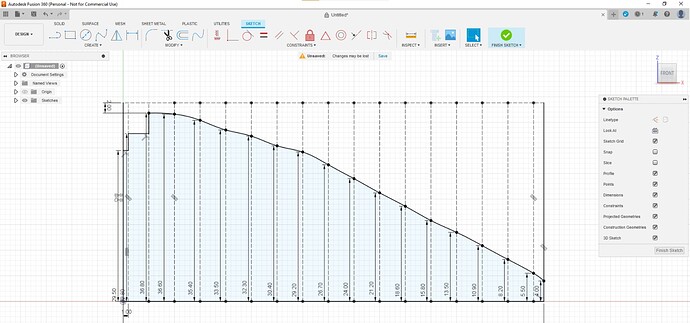

Then I measured the height between the ceiling and the first horizontal cleat every 5cm

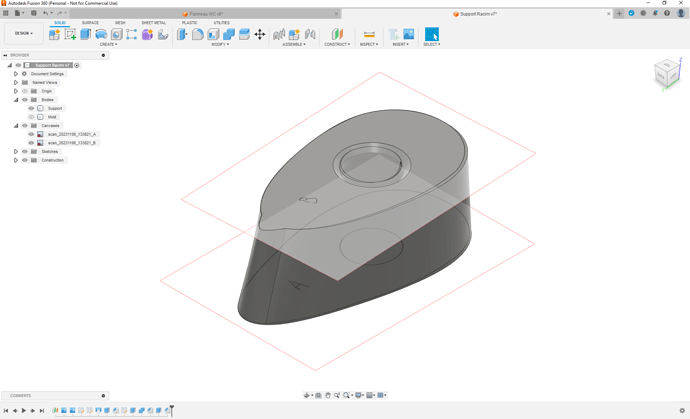

I then reported this in fusion360 and drew a spline…

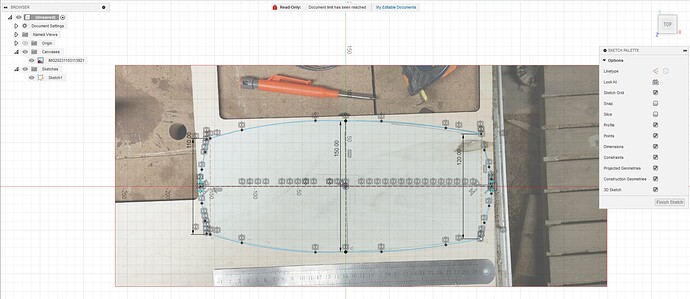

I then cut a prototype out of cardboard

Well… yeah… Make that 5 prototypes -_-

… and made of mdf scraps because I had no cardboard left…

In the end, I laser-cut the final design out of 3mm hardboard

Added a few additional cleats and nailed the panel to it…

Traced out the lower part, cut the two bottom notches with the laser and installed it too

Caulked the whole perimeter, this had some 4-5mm gaps on the ceiling that were pretty hard to fill -_-

Added shelves and voilà

Ok, done… so, what went wrong?

The whole measuring and shaping process was a nightmare…

Measuring was hard, and I needed 5 prototypes to get the shape roughly right…

I was not able to efficiently tune the shape, as moving a single point could impact the whole spline or panel fitting

In the end, removing spline points down to one measurement every 20cm yielded a smoother/better result

Also, every small adjustment means a whole lot of walking black and forth between the office, CNC, and construction site

Because every attempt means cutting a new prototype or re-fitting the previous one on the machine, each iteration takes quite a long time…

What worked well?

The laser is particulary suited for hardboard cutting

No tearout at all, the cut is perfectly clean, which can be hard with a jigsaw…

Eg: this was perfect for the two little notches at the bottom, nice clean edges , perfect 90° with no overshoot…

How would I do it again?

I’d probably keep the measurement and laser cut approach to get a rough approximation, and finalize this with a scribe and planer fine tuning to get the perfect fit

Hope this “weird” report can help you decide wether a CNC approach fits your next project and help you save some time maybe ![]()