I tried printing TPU on the Mini. The first try was a disaster, using the settings for PLA, the TPU getting stuck because a Bowden Extruder does not really like to push to the nozzle.

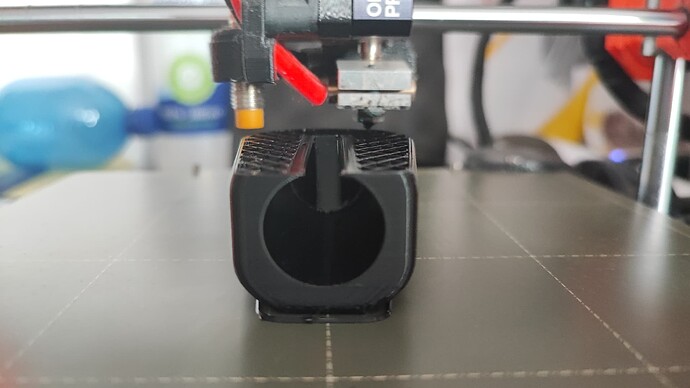

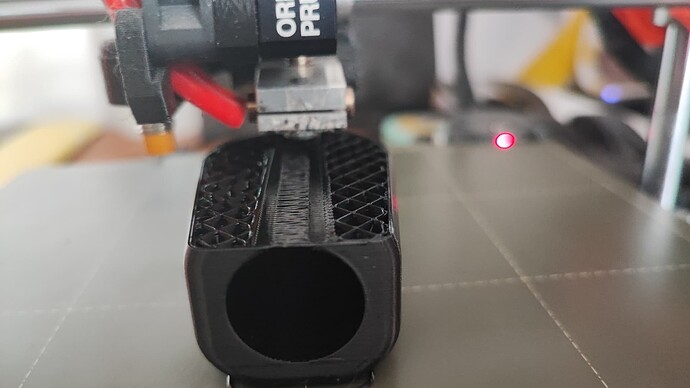

Second try was with the settings for AmazonBasics TPU in the slicer, with half the speed and 235°C instead of 210 and it worked like a charm. Let’s make a guessing game: Which one is made from TPU, which is PLA (it’s kind of obvious, but I am still proud ![]() )?

)?

One on the right is TPU?

Never printed TPU yet, but your results are encouraging.

Yes, the right one is TPU. It does look a little less smooth, but judging from other pictures online of TPU I think that’s just the way it looks like. ![]()

Not bad at all for TPU on a bowden! Must be a nice, constrained filament path on that mini?

Yeah, I guess it is. ![]()

First (bottom) vs. fourth print (top). I think the humidity of the filament was better, since I had it in the drybox overnight and only printed the fourth foot today. Nearly non-distinguishable from PLA.

Drying makes quite a difference with TPU - for me it needs proper heat drying, but if it lives in a drybox in moderate humidity that is obviously good enough to make a big difference!

Not the first time I’ve heard about humidity playing a factor with TPU. I have two spools of NinjaTek, that I still haven’t “played” with yet.

I thought I was impressed with v1, until I see it sitting beside v4. 4 is now making 1 look bad. And 4 is making me want to get mine out, and print some aircraft wheels, which was the reason it was purchased in the first place.

What is your layer height there?

0.2mm.

I also thought 1 looked good, but midway of 3 it changed to look better. That was the filament that was already in the tube. So I reprinted the first three. ![]()

I’m digging it. TPU sucks up quite a bit of moisture. Dry, dry, dry.

I printed some vacuum hose adapter parts using Hatchbox TPU on a Prusa i3 MK3S+. I read a bunch of articles first and then set up a Simplify3D profile. The major trick is apparently to turn off retraction. You get a lot of stringing, but your hot end doesn’t get clogged.

Overhang? Bridging? TPU doesn’t care.

I am pretty amazed.

It’s going to be a foot for my cargo bike’s stand. Costs 7.5€ if I bought it, now it’s 50 cents.

I’ve really got to try some TPU soon. Have 2-3 spools of it but never got up the courage to try it lol. Need to figure out how to print a brush for the LR3 dust shoe lol

Yea, tpu is very hydroscopic. Needs dried out before any print, even if it lives in a dry box.

You are totally making me walk around the house, looking at things, trying to find something that needs a TPU fix for, to give me a reason to break the seal on the ninjatek.

Some table or chairs need rubber feet, I am sure of it. Maybe something to stop your kids/pets/wife from banging the door against the wall? ![]()

These were $45.00 to buy!

Easy to print though! ![]()

[(https://www.printables.com/model/119841-ball-feet-for-helinox-chairs)

I noticed that I have wet filament after the first few layers when printing TPU. That’s the one section where it is not in tubes but in the Bowden extruder of the Mini.

The new Prusa Slicer Warned me to enable supports and use a brim… Lolo… I am glad if I get the TPU from the print plate at all. Last time I had to use my teeth… -_-