I am curious what durometer TPU people are using for their bristles. I printed some just now for my V3 floating dust shoe with 95A and it seems stiffer than I was expecting. Haven’t tried it yet though.

That’s what Ryan uses for the ones he sells in the shop. It’s also what I printed from. The stiffness is to keep them from getting sucked in by the dust collector and not staying in contact with the workpiece.

This is what I am using as well. I am 99.9% sure that is the suggested type to use

95A. Ditto. Seems soft enough not to cause problems with the work.piece.

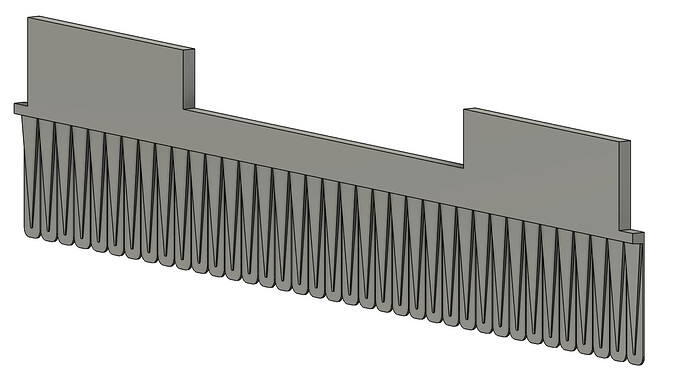

Large portion of the LR4 bristles should be one layer thick. Able to share pic of your prints/slicer?

Tried to find hints or recommended printers settings for vac hose bristles at https://docs.v1e.com/lowrider/#printed-parts. Couldn’t find there, but did find printer settings hints in the Printables description for the router specific vac parts. Personally used 0.6mm nozzle, 0.32mm layer height, 5 walls for the TPU bristles to help minimize infill and retractions that increase risk of jamb. Bristle finish seem smoother for it. Thoroughly dried overture tpu 95A filament came out more flexible than some of the earlier bristle designs Ryan shared with beta folks. Have some high speed printing TPU that’s easier than regular TPU.

EDIT/DISCLOSURE: I haven’t printed much TPU, so LR4 was a neat opportunity for me to learn/experiment.

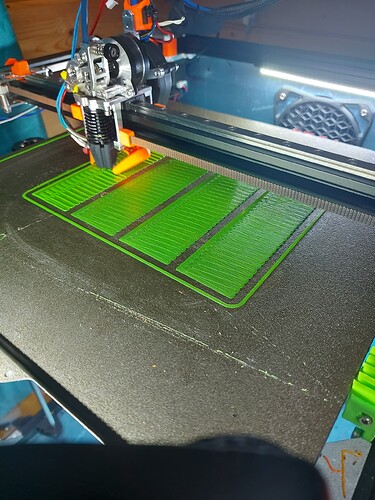

I am only now printing the V4 bristles. The ones I had posted about are for the v1.1 floating dust shoe that Doug made for the V3. The V4 bristles are designed a lot different than the ones in Doug’s design so that’s likely why I thought it was too stiff. Once the v4 ones come off the bed I’ll compare. I printed the V3 ones at 0.2mm and the bristles were solid infill. The v4 ones I did 0.28mm height with 1 wall.

Yes, Ryan’s new bristles are actually engineered and well designed, modeled with TPU in mind, whereas my earlier bristles were initially soft EVA foam and the notion of printing those in TPU was both an untested side option and not something I actually did. Up until LR4’s TPU bristles, the bristles I was using before were all soft EVA foam. As others did, my LR4 bristles are TPU 95A.

I threw them both in fusion and combined them. The bristles are about 8mm longer but we’ll see how they do.

They’re about to print now.

I’m printing some bristles at the moment I’m trying 40mm and 42 to see how they behave. If they are too flimsy I will thicken them up a bit.

The bristles finished and I printed an extra set in case I need to trim it shorter. The LR4 style bristles are definitely more flexible so yes 95A works well. The combo remix LR3 bristles fit into my dust shoe and look good, only problem is the shoe cracked when pushing it onto the mount so I’ll try reprinting in PETG for a bit more flexibility.

I’ll put an update pic on here when I get the new shoe made. I have every intention of upgrading to the LR4 but for now I want to get the LR3 usable as the only thing I’ve cut with it so far is the strut plates. I hope to cut a table for the LR4 with it, then tear down the LR3.

Ryan made 32mm bristles as well. Any longer and they will certainly get tangled in the endmill when cutting deeper cuts. You absolutely should keep that in mind. 32mm is very close to reaching the endmill already! ![]()