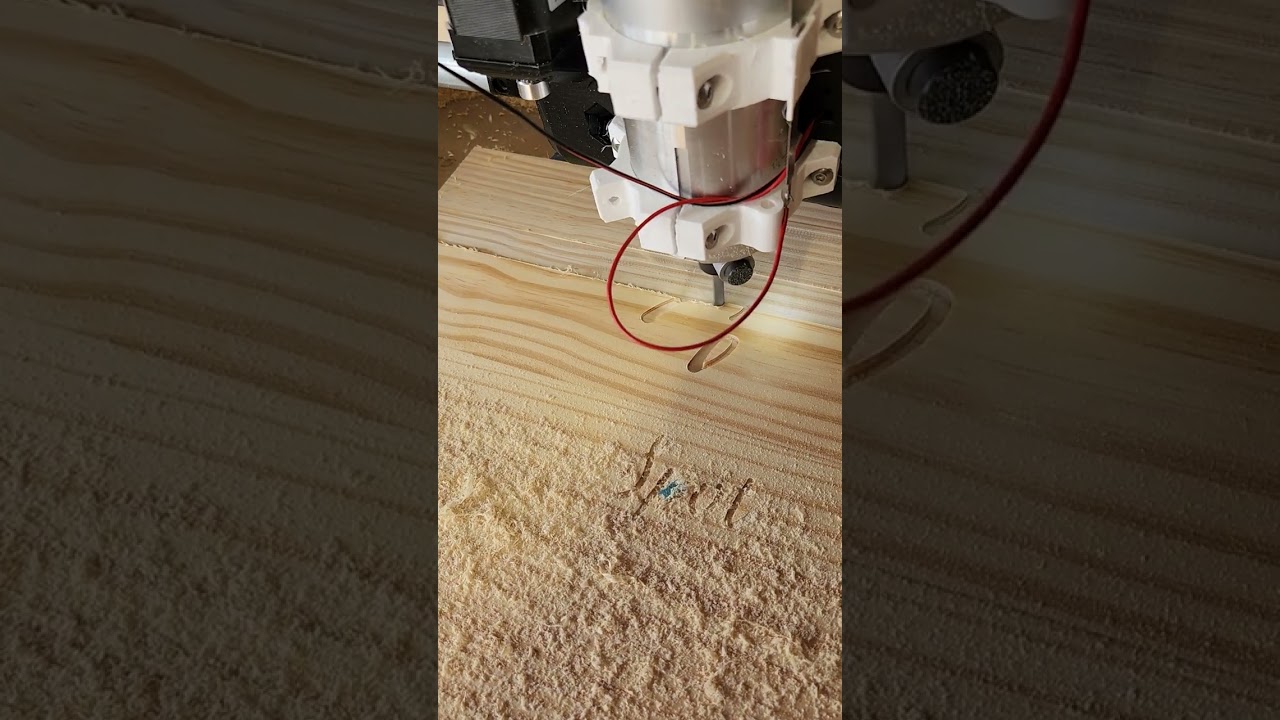

So i screwed up a carve and today i learned we have a delete button ![]()

Sorry bad on me. 6.3 mm 3 flute. Pushing 1500mm minute from jaimes gcode.

3.5 router and 4 mm stepover.

And 3mm deep.

Looks like you need to print you a dust shoe! ![]()

I may be reprinting alot. I seem to have flex. I am going to start with just the braces. I need to het plates too. (Will need to save for that, i do not want to do metal. My heart is in woodworking!)

I noticed real bad on the oval.

I also saw it in the surface i ran!

Yeah we were worried about that with the PETG. I just took my big full sheet off the table about an hour ago. Hoping to find time here and there to rip it apart and put the LR4 together. I have everything printed just gotta find time to assemble lol.

Kind of a bummer. I should have listened! But maybe i can stop someone else from having problems! @vicious1 you may have been correct ![]()

My core is fine! The large parts seem great! But i can see flex from x max to x min. Maybe a quarter inch! I have a video but need to get around as i am being taken out for bday dinnner!!

Happy Birthday Sir!!! Enjoy your dinner!

So here it is. It is really uncontested, by which i mean it is free to move that far! I need to fully inspect, but i expect it may be my petg!

Did you have the beam all the way up for that? Like Z homed?

Dont think so

I may have just found it. Pipe was slipping in brace on x max. I watched it rotate! Tightened all the strut screws and now can barely pick xmin up!!!

Awesome! I do remember Ryan saying something about the PETG being slippery on the EMT or something to that effect. Hopefully snugging it up more was all you needed.

just got this vintage table (solid) for 10 bucks. This is my new cnc table!!! I will be shortening my lr4 and making it fit this table!!! Flat and solid all in 1

Wow - OK - yeah - I printed my LR3 in PETG and had several concerns, but that much movement (even on a less rigid design) always traced back to something being loose. For the first month of use, I was always testing the core by hand, and tightening anything that had loosened. I probably didn’t check the braces often enough. I had problems keeping the bearings on the core in contact with the EMT (often like 1/16th to 1/8th of a turn), with the router mount loosening and needing a 1/8th turn to tighten back up, with the dovetail on the bottom of the belt anchors allowing it to tip (needed reprint, ended up hiding with Doug’s mod), with none of the nut traps working (without CA glue assistance after the first install), and with loosening of the attachment of my dust shoe (non-stock, Doug’s rail mounted version.) Some of this could be due to the heat in my garage too, but I did replace some parts over time to try and combat my impression that it was just a little harder to keep everything dialed in with PETG.

Right now i am not sure i would recommend petg.