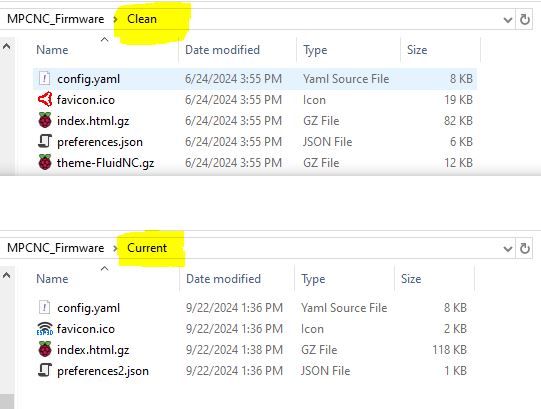

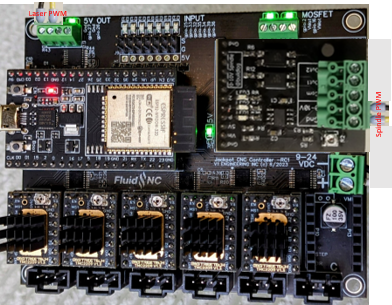

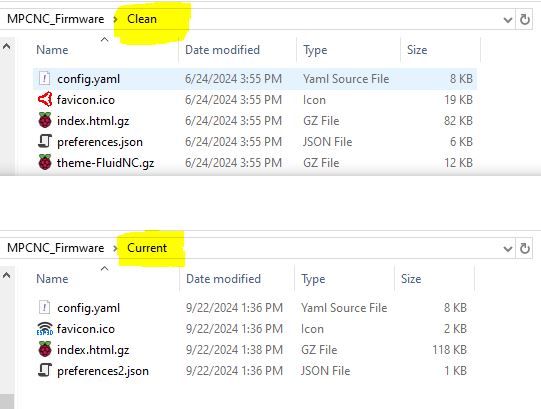

Ok, I did a little poking around and it didn’t look like the firmware/config files on Github weren’t what came pre-loaded on my Jackpot, so I downloaded a copy of what came with it for a later review and possibly reload if the new software broke anything and loaded the clean software from Github’s MPCNC UI V3 repository.

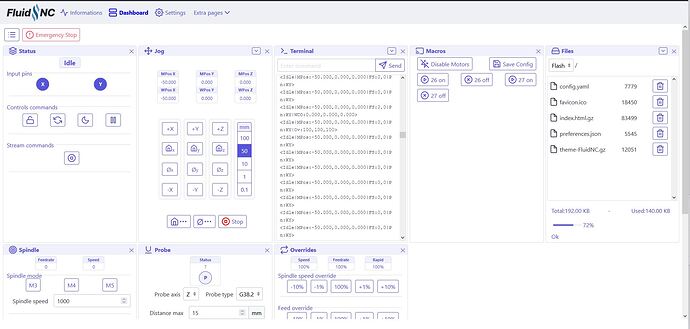

The entire UI layout has changed and it took a second to get used to it, but it’ll do.

So to begin for today after the software changeout…

- I fixed the Y-stepper issue from yesterday and re-squared my axes.

- I removed the spindle from my config.yaml file and left only the laser in there to see if I could isolate the issue.

- I ran the following code M3 S100, the laser of course still did nothing.

- Then on a whim I just clicked on one of the Jog buttons in the UI and BLAM, laser fired right up.

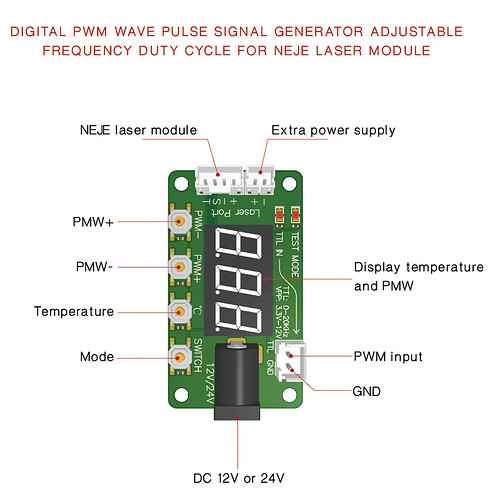

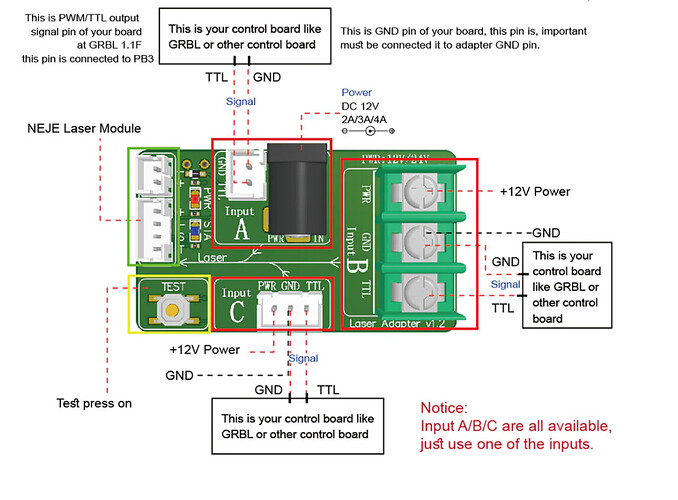

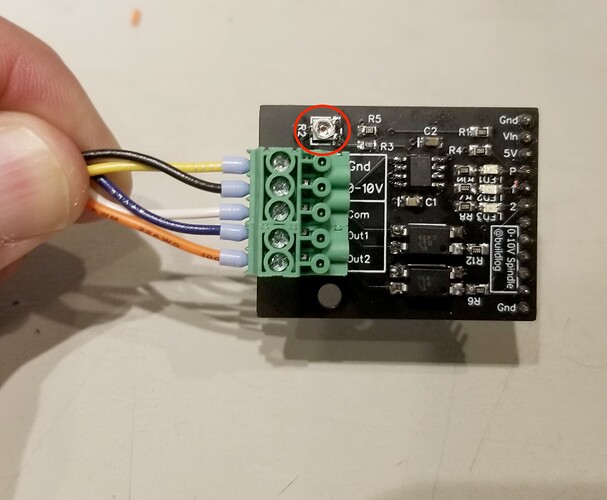

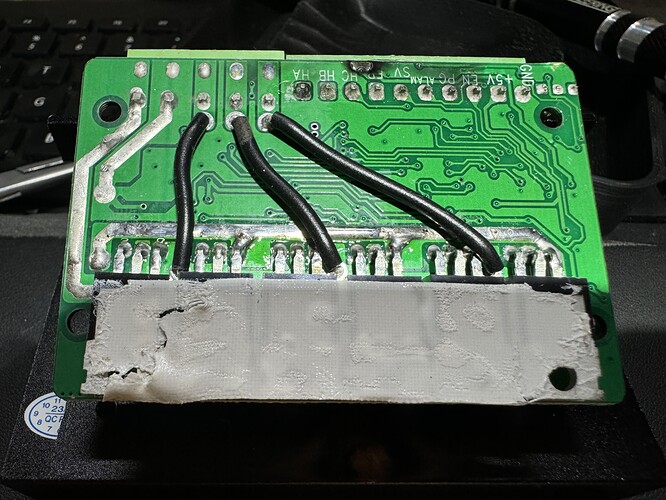

- I was also able to detect PWM voltage on the tester board at this point. I know that one sounds obvious, but I still liked seeing the number on that thing go up with the PWM setting.

- M5 turned it off as it was supposed to.

M3 S100

ok

$J=G91 G21 X+50 F1000 <-- Laser lit up here

ok

<Jog|MPos:-48.520,0.000,0.000|FS:1000,100|Pn:XY>

<Jog|MPos:-31.640,0.000,0.000|FS:1000,100|Pn:XY|WCO:0.000,0.000,0.000>

<Jog|MPos:-14.760,0.000,0.000|FS:1000,100|Pn:XY|Ov:100,100,100|A:S>

$J=G91 G21 X-50 F1000

ok

<Jog|MPos:-15.280,0.000,0.000|FS:1000,100|Pn:XY>

<Jog|MPos:-32.080,0.000,0.000|FS:1000,100|Pn:XY>

<Jog|MPos:-49.120,0.000,0.000|FS:0,100|Pn:XY>

M5 <-- Laser shut down here

ok

I’d read about some safeties built into the Jackpot/FluidNC regarding lasers where the unit had to be in motion for the laser to power on via PWM. Guess that’s confirmed…

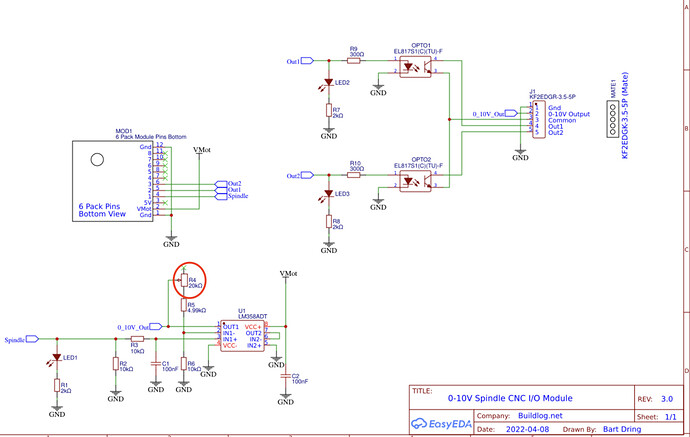

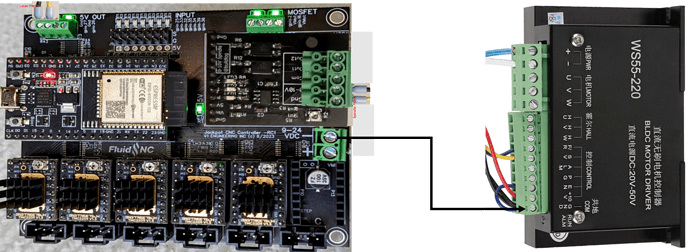

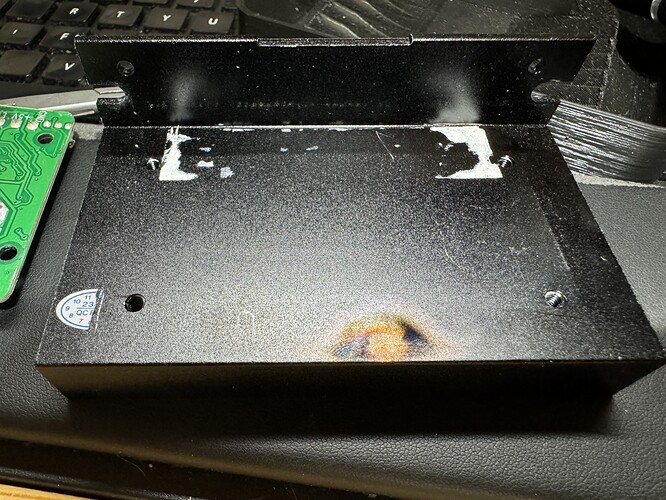

Just for giggles and shits and wasting time, I tried it and my laser stops working when I have it and the 10V spindle parameter defined. When I comment the 10V section out, the laser works again. Sadly however, commenting out the Laser section does not make the 10V Spindle PWM adapter work even with the firmware/software change. It still shows 10V output at S12000 (Max Speed), but apparently doesn’t generate enough amps to trigger the spindle to fire. I’m starting to wonder if I have a bad 10V board maybe?