'Ola, my name is Linda and this is my MPCNC story.

It begins around 2018 when I was posessed by a dream of a true DIY REPRAP CNC and found a Vicious1 and MPCNC and the work begins ![]()

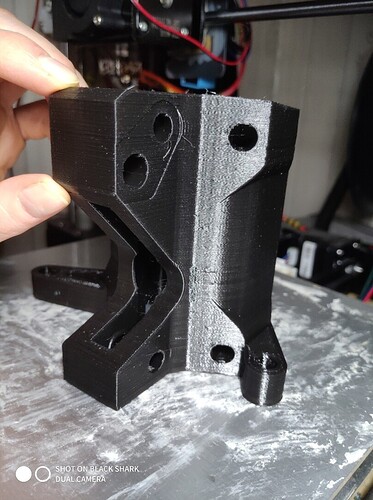

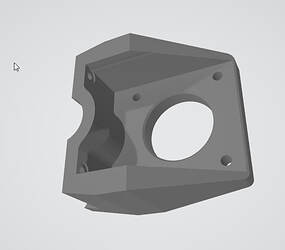

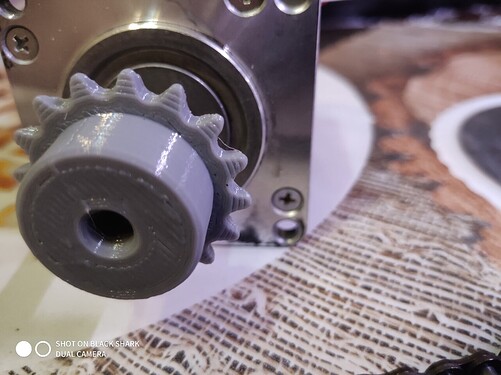

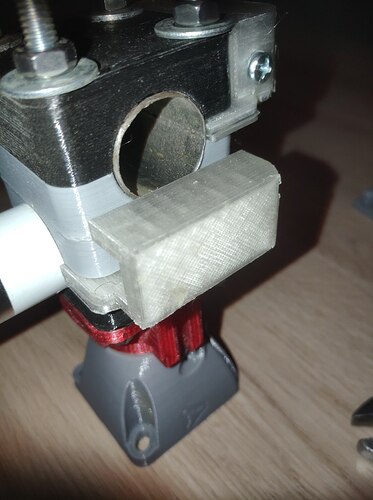

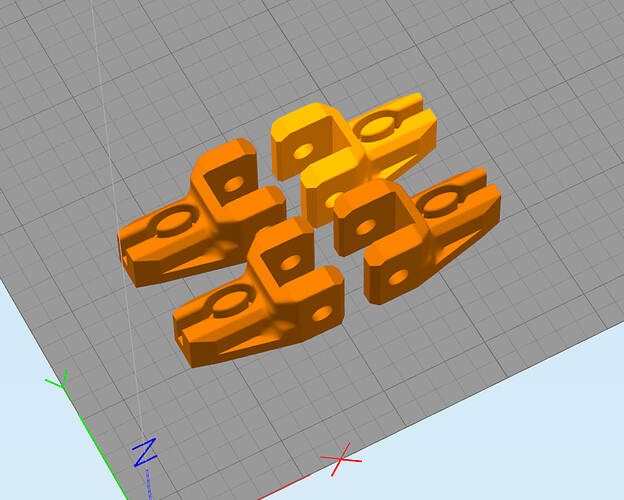

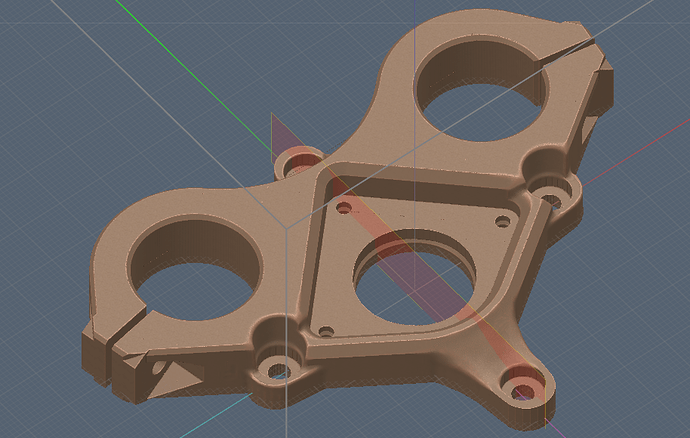

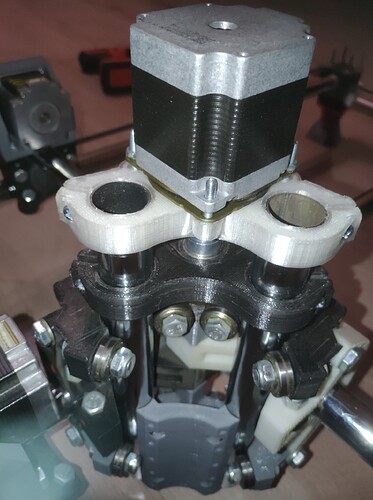

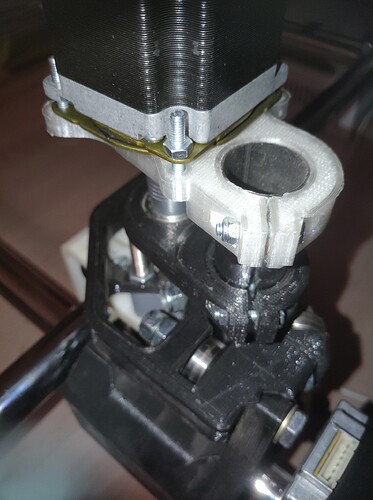

At first the idea was to use a nema23 instead of nema17 and i made my own nema23 motor holder:

Btw if someone looking for my nema23 holder mod: here it is

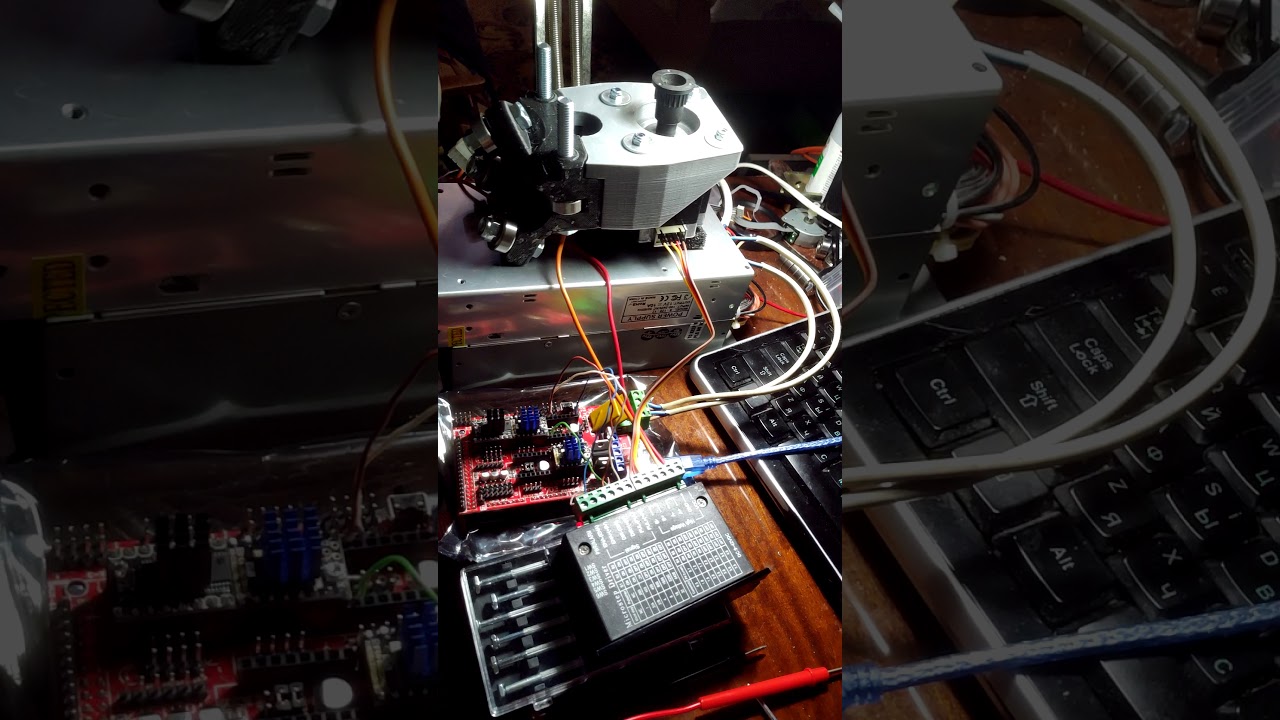

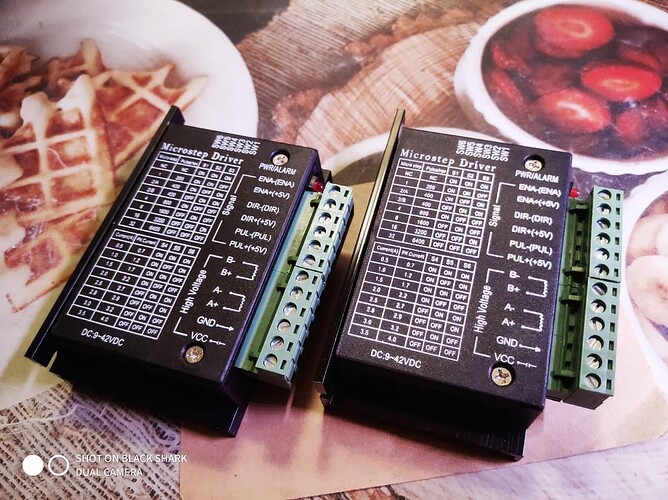

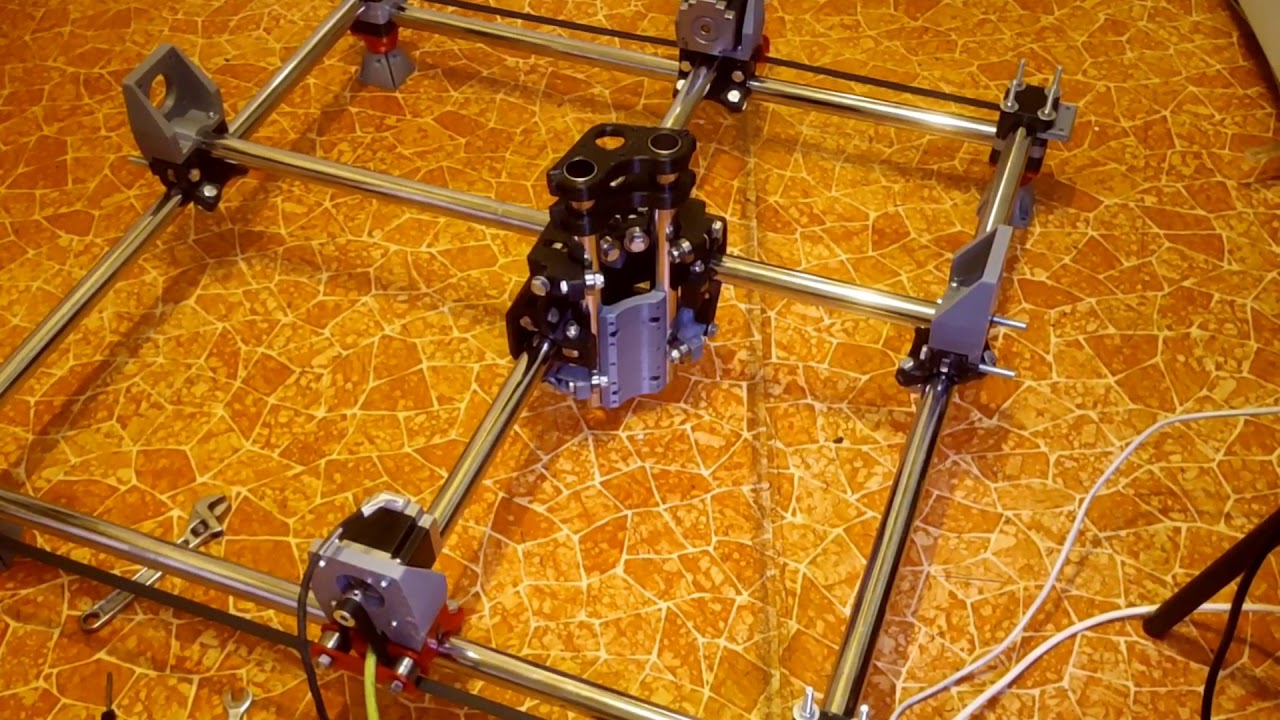

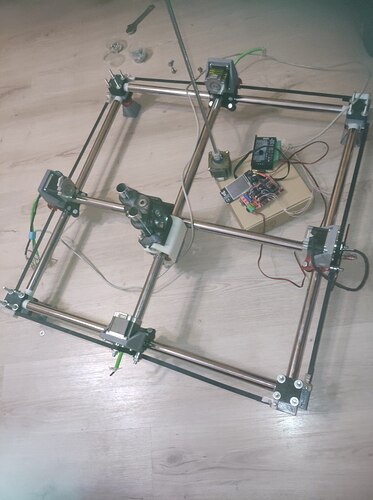

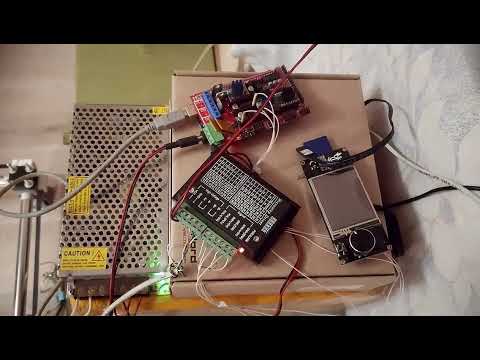

After that the madness threw me forward to the experimenting and testing how to control the motor and so on:

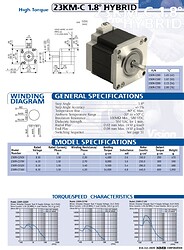

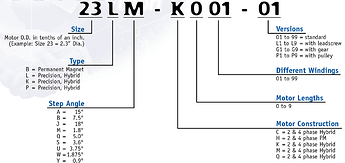

Nema23 ( 23KM-C051-09V ) test on Ramps 1.4/TB6600 driver

And and I trapped around way to use TMC2208 or TB6600. And left the TB6600 as working version.

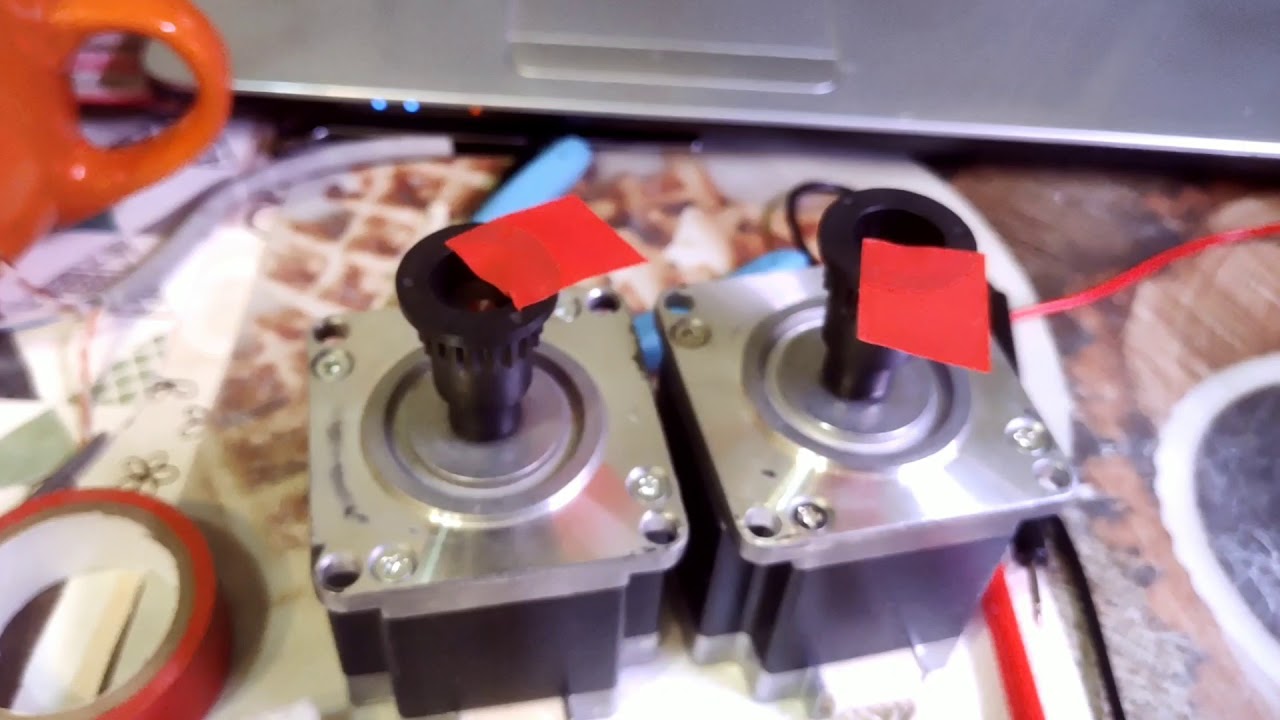

Than was a battle to control 2 motors via one driver:

After some results I focused to use 1 motor per one driver instead of 2per1.

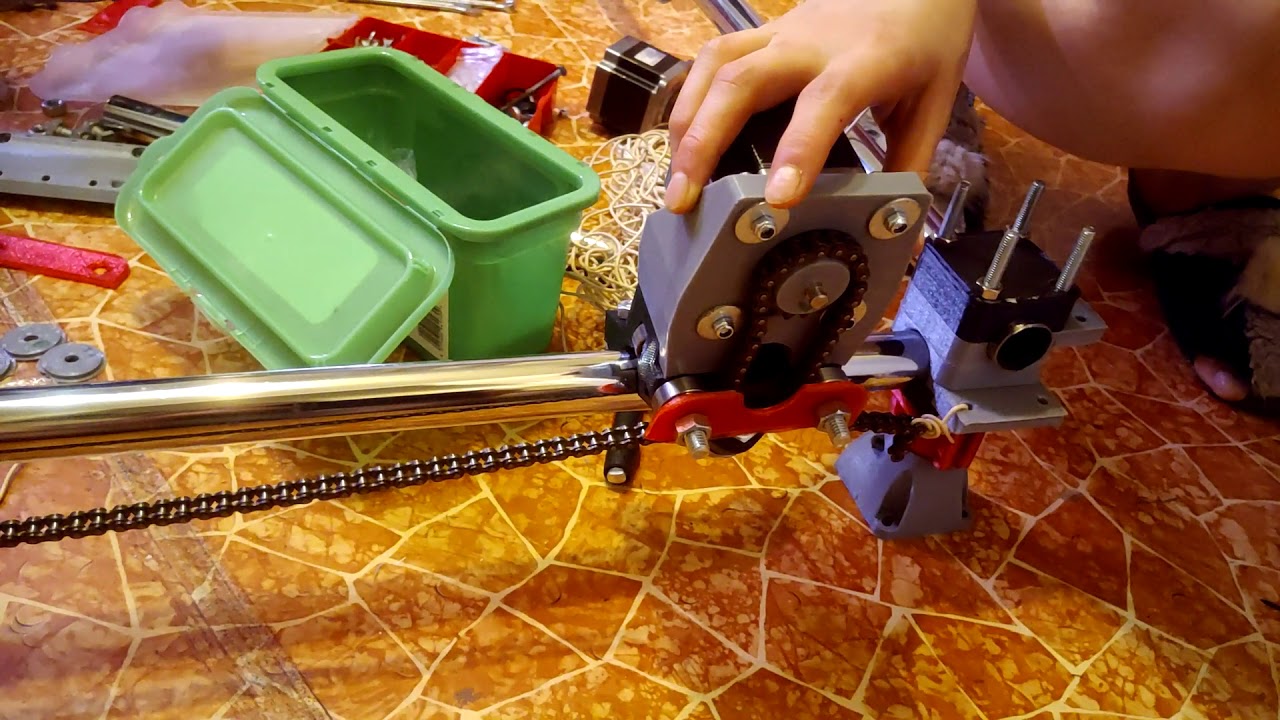

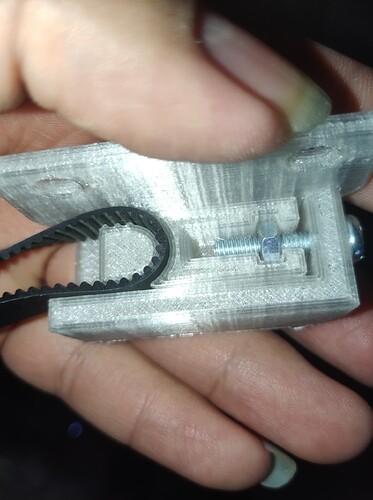

Than becomes the EXperiments. I has an idea to use a chains instead of belts… why not? I made a prototype:

It was funny i can say:

But in some case im back to the belt version and left the chain to the history for no reason mb become bored XD And may be some day i will make a chain-based version too…

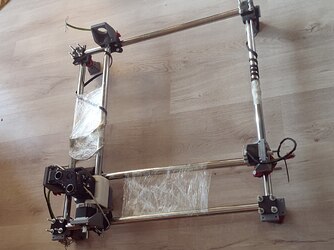

And after that was a long hiatus cuz of job, and I moved to another place where was no place for crafting and storage and so on… MPCNC prototype was left alone at the garage till the modern day and emerged ![]()

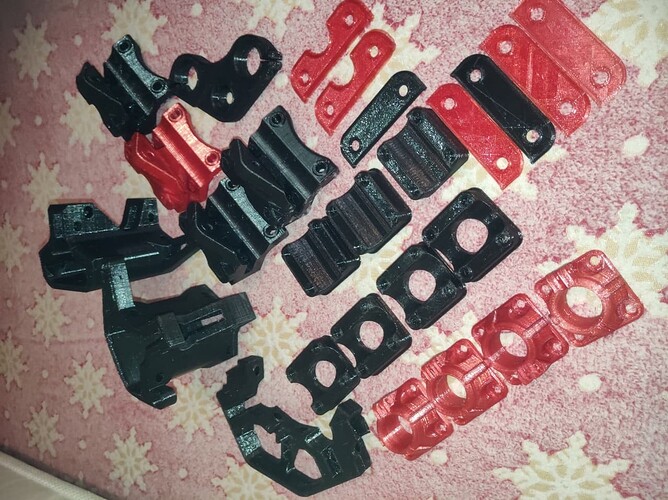

I become smarter from those days so some parts was remade.

I eventually found that a lot of versions are made after my pause: burly, primo and mb somethem betwixt. In this way my version become old paps but I love it and continue my job around it.

Uhuh:

The next steps will be a new Z-axis rail, the old one are skewed, new z-motor mount adapted for nema23, cuz i forget to make a new model based on nema23 concept than I become lazy and stopped on the adaptor 17-to-23 version.

To be continued (Sure if this story is interesting) ![]()