Been using my newly built LR3 pretty much every day, cranking out a variety of practice stuff in plywood and hardiboard, but I recently went to my local lumber yard and picked up 9 bdft of walnut for a few projects.

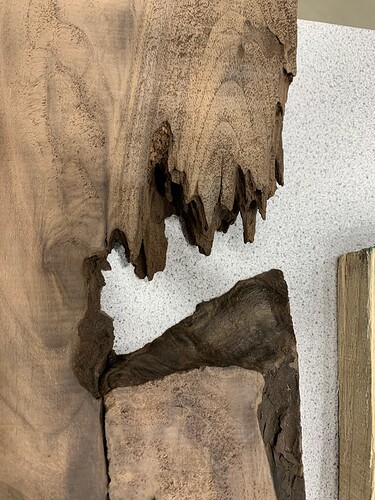

One of the boards had a split at one end, and a gnarly rotted out burl knot- so I sectioned those pieces off at 20”, ending up with a 36” board, and a 6” x 5.5 cut-off

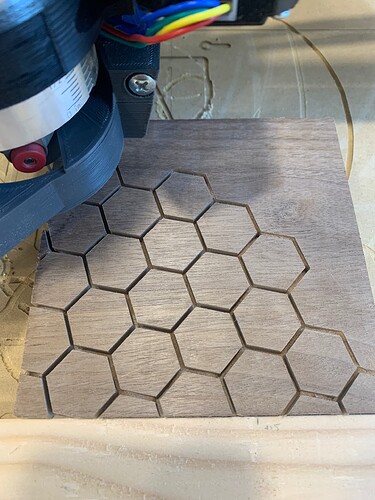

Been messing around with Carveco (3 months free trial, which is awesome) and came up with a nature inspired geometric pattern- the honeycomb hexagon.

So I used a 1/16” spiral down cut, and engraved it 1/2” into the piece - took all of 9 minutes running the bit at 3mm step down, 20mm/s.

I also took the same bit into my handheld router, and cleared out 3 of the cells (I forgot to save the toolpath for that job, lol)

Then I whipped up a batch of Totalboat high performance epoxy, threw in some copper and gold mica powder, and poured

24 hours later, double sided taped it to my bench, added a 1/8th round over with the router, and hit it with the ROS, going 80-120-180-220, before water popping to raise the grain, letting it dry and repeating the sanding.

20 minutes in a mineral oil bath, wiped down with a rag, then staged for a product picture for my company Facebook page

And viola! The ‘Honey Board’, which looks like a mini charcuterie board, but is the new cool fad. I hope.

Since posting, I’ve got orders for 3, including a custom engraved one, and may have an ongoing consignment order for 30/month out of an apiarist store in Tucson, contact through a friend!

Also- here’s how the other ends of the board turned out-

Will absolutely do it like that the next time.

Will absolutely do it like that the next time.

(Though the one inlay is too light and does not fit exactly, see other thread for inlay woes… :D)

(Though the one inlay is too light and does not fit exactly, see other thread for inlay woes… :D)