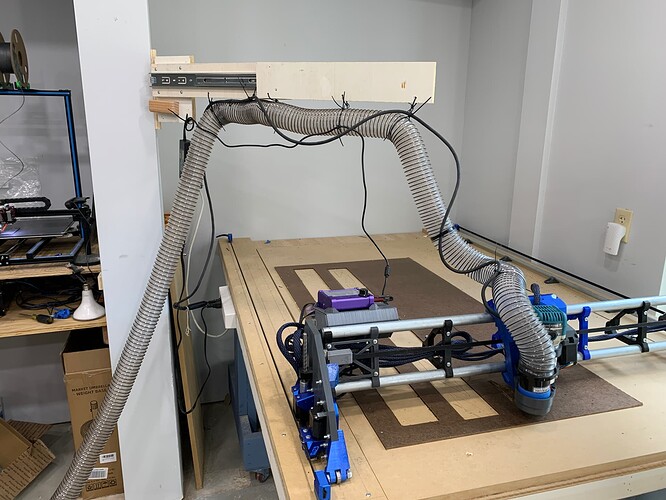

So, it might not be pretty, but the over-table boom air for the 2.5” dust collection and power cords works great.

I didn’t even have to cut anything- threw it all together in 25 minutes with scraps that were already sized, and used a surplus drawer slide for the folding mechanism (so the arm doesn’t arc quite as much as it pushes back compared to a fully rigid arm)

V2 will be have be mounted on a French cleat, a Voronoi pattern and some integrated hooks so the whole thing can be packed away when I need to move/stow the table