@Avatario

Hi Christian, it’s been a year since I installed your version of the SW on the TFT and after a long time without using the Lowrider3, today I noticed a strange behavior. If I use the Z-Probe button, the milling tool descends until it touches the plate and then retracts a few millimeters (measuring with M114 I measure 12 mm, my Touch plate is 5 mm thick, so it retracts by 7).

Do you remember if this behavior is correct?

I saw that you no longer maintain the SW TFT so mine is just a request for information.

However, I solved the problem by making the touch plate directly in Gcode (inserting the start gcode in EstlCam)

Thanks again for your work.

Hi Gianpaolo,

A year already? Gosh, time flies…

As far as I remember I configured the gantry to stop when hitting the touch plate in your version of my software. In my configuration, the gantry retracts to make it easier to remove the touch plate. However, you are good to go if your Z is correct, i.e. Z=0 is at the surface of your workpiece after probing.

Best, Christian

My current software does the following:

G38.2 Z0 (Probing)

G92 Z6.5 (that’s the height of my touch pate)

G1 Z16.5 F450 (move gantry up by 10mm)

If you found it useful I again would compile my software for you for your touch plate height of 5mm and a retraction of say 10mm. I’m not using the TFT anymore as I moved to GRBL, so I can’t test it. Would be worth a try?

Yes, thank you, why not. If it’s not too much work for you I’ll be happy to test it.

With this version how should I set the Gcode startup after the following steps:

G38.2 Z0 (Probing)

G92 Z6.5 (that’s the height of my touch pate)

G1 Z16.5 F450 (move gantry up by 10mm)

(I mean how do I correct the lowering of 10 mm in the working gcode)?

If I’m not asking too much, for me, the best method would be to do a double check first with G38.2 Z0 (Probing) as it is now, then lift the gantry and probe again at low speed.

You don’t have to do the step of correcting the thickness of the tuch plate because I prefer to do it in the start gcode.

(you should also enter the string lift to remove the touch plate and suggest me how to compensate for the lift in the working gcode)

Tell me if you have time to set up this second version, but don’t feel too busy for me.

Thank you anyway.

Even if it’s late, Happy New Year

So this actually leaves the bit 16.5mm above the work, but that’s OK, because the firmware knows that’s where it is. When your gcode program says to move to Z=0 it will drop by 16.5mm and start at the actual zero. (It would be a problem though if you started your program with G92 X0 Y0 Z0 because you would then be telling it that the current location is Z=0, which isn’t what you want, since you established the Z=0 point with the probe.)

Anyway, the compensation for wherever you command the machine to go at this point is built in, because it knows where it is relative to the zero point that you set using the touchplate. If you suspect that the zero point is not correct, just do it again.

3D printers (And the CNC machines) do this with switches, because we can hit them at high speed without damaging things, and doing a high speed pass saves time, and we can get the low speed accurate pass afterwards. Generally when probing to a touch plate, we’re using a sharp bit that we want to stay sharp and a touch plate that we don’t want to damage, so we probe slowly in the first place. In essence, we’re doing only the low speed pass, because we don’t want to damage the endmill or our touch plate.

I suppose you can add a line to do this, but when the probe action lifts the machine by 10mm and stops, that’s good enough for me. This isn’t at the start of a program where it will go on and begin cutting, after all.

G38.2 Z0 (Probing)

G92 Z6.5 (that’s the height of my touch pate)

G1 Z16.5 F450 (move gantry up by 10mm)

Might I suggest that you change the G1 there to a G0? I suppose for Marlin it doesn’t matter, but it can make a difference with some tools, as a G0 will turn off things like lasers and spindles if they’ve been properly defined, where G1 doesn’t. Marlin will still obey the feed rate at least.

@Avatario

As you may have understood, I’m not good with gcode,

after examination I have come to the conclusion that your first suggestion is very correct. So:

G38.2 Z0 (Probing)

G92 Z5 (that’s the height of my touch pate)

G0 Z15 F450 (move gantry up by 10mm)

so you also introduce DAN’s suggestion

Thanks

@SupraGuy DAN

Thanks for your comments which helped me understand some steps

Thank you and likewise! Have great fun with your tools this year!

Tell me if you have time to set up this second version, but don’t feel too busy for me.

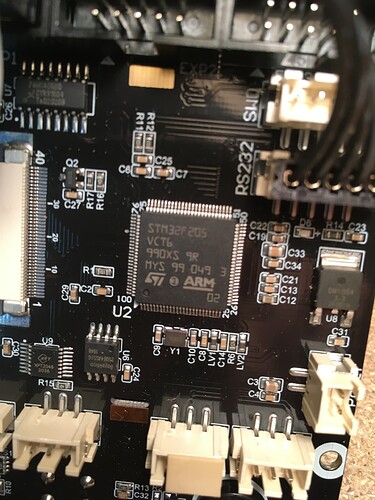

No problem at all, happy to help. Can you please remind me of what is your TFT board version? If you are unsure a photo of the TFT board’s main processor would help…

Please try the attached firmware:

BIGTREE_TFT35_V3.0_E3.29.x.bin.zip (121.4 KB)

Many thanks, I will try it in the next few days and then I will inform you of the result.

Hi Christian,

I installed the new TFT FW and tested.

Unfortunately it still behaves like the previous version:

When the work starts the bit does not touch the piece to be worked but goes through the entire cycle in the air, remaining raised by about 5 mm

so I think the problem lies in the initial part of my Gcodes.

I wonder if you could help me look for the error.

I attach the first lines of a typical Gcode as created by EstlCam

G90

G92 Z5 ; lower 5 mm to compensate touchplate

G00 X0.0000 Y0.0000 Z0.0000 F2100

G00 Z15.0000 F480

G00 X0.0000 Y0.0000 Z0.0000 F2100

G00 Z10.0000 F480

;No. 1: Hole 4

G00 X19.9819 Y19.9869 F2100

G00 Z0.5000 F480

G01 Z0.0000 F120 S24000

G01 Z-0.4500 F120

G01 X19.9780 Y19.9965 F720

My workflow is as follows:

- I send the LR3 to Home

- replace the bit if needed

- I place the touch plate on the piece to be milled

- I reset the height with the Z-Probe button

- after removing the touch plate start printing the gcode

Your comment/check would be greatly appreciated.

Thanks again for your effort

Take out the above lines of your starting sequence.

My probing sequence sets the correct z=0 with G92 Z5.0. So, after this command, the tool is touching your 5mm thick touch plate at z=5.0; with the following G1 Z15.0 I move the gantry up to z=15.0, ie up by 10mm.

When you now perform again a G92 Z5 as you do in your startup sequence, you are telling your controller that your tool is at z=5.0. In reality the tool is at z=15.0 which leads to the fact that you are cutting air.

G92 does not move the gantry!

Hope this makes sense.

Many thanks, I will try and come back to you

Many thanks, it works perfectly.

I knew I was terrible at Gcode…