Ah. I don’t have that TFT I have one model down so it doesn’t have the two different options. I only have touchscreen mode.

Well, I finally tracked down the issue with the z motor releasing and falling on job completion. The release of the motor occurs in the TFT35 display’s firmware and is hardcoded as you remembered , Dan. It is in the printing.c file around line 160. The offending line is : mustStoreCmd(“M18\n”);

These screens are nice but really need to get an overhaul. To many behind the scenes things going on.

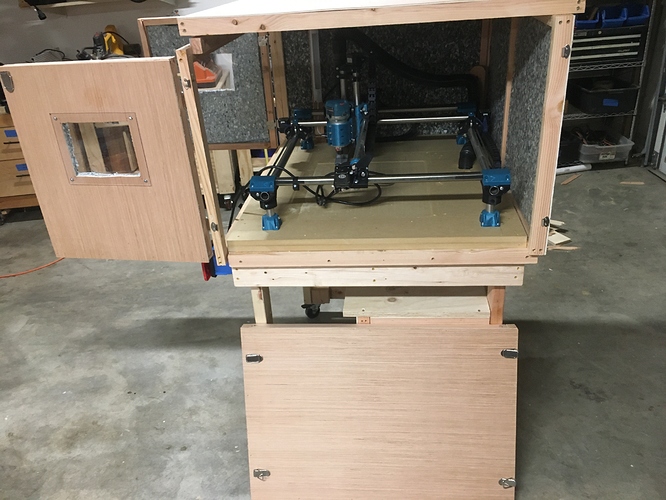

Well, I was slowed down a little in completing the cabinet build for my Primo. I fell and cracked a couple of ribs. Don’t wish that pain on anybody, especially when you cough. Wow!!! While still in pain 10 days later, it is gradually subsiding and I was able to slowly complete my cabinet.

I first built it with 1/2 plywood and 2" thick styrofoam, but it took 2 people to lift it off the machine, no good. I tore that down and built four side panels and a top that all latch together with a very light, 1 x 1 1/2 inch fir box frame with 1/4 skin and lined with carpet padding. I can remove any side or the top for access very quickly or tear it completely down in snap with no help. The two layers of 1/2 carpet padding reduced the sound much,much more than the styrofoam. I have since read up on the sound transmission issue and found that softer materials do much better for sound deadening.

I also built a vacuum cabinet underneath and soundproofed it as well. Also put a baffle in it.

And I added Emergency switch, router safety switch, and light control together with a SCR to control on/off of the router and vacuum through the software

.

TFT35 touchscreen interface:

Nothing left to do now but put it to work.

That’s a nice clean build. I built my enclosure over a year ago and still haven’t gotten around to putting doors on it. Maybe I’ll finally do that in the next month or so.

I had dust collection on the Burly version of the machine, but nothing on the Primo yet. I was thinking about just hooking the dust collector up to a 4" port on the side of the enclosure. That would only grab the light stuff floating in the enclosure, but that’s what’s worse for your lungs.

Wow, impressive!! The cabinet was too heavy, so you just built a new one. Took only two broken ribs… all the best to your health

For sure, with no doors you would at least create negative pressure in the box, and as PLUS, it could double as a spray paint booth if you ever got tired of your mpcnc! ![]()

![]()

![]()

I completely agree, to many moving parts. I also feel that way about Marlin, wish there was a slimmed down version just for CNC work, it is a bear to wade through all that extruder,heater,bed leveling,etc,etc everytime I want to modify or test something for the cnc.

Marlin took grbl, which was built for CNC work and added the elements to support 3D printing. It’s an interesting “full circle” sort of situation to watch people wanting to turn all that extra off and get back to the CNC basics.

Boggles my mind to think it takes almost 5 minutes to compile Marlin to control up and down movement of a router and do x,y positioning. Back in the late 70’s and early 80’s I wrote assembly code for a Motorola 6809 running at 1 Mhz for an experimental x,y laser scanner and a homebrew x,y plotter, both of which used steppers to control movement and had acceleration/deacceleration routines. I doubt there was more than 8k of memory(which was a lot back then)and compile time was on the order of a few seconds. Aaah, the good ole days!

I bought the SKR v1.3 board mainly because of price,small size, and plugin motor drivers. Little did I know or understand what I was getting into with Marlin. I really wanna go back and design a board that an Arduino Nano and the 5 stepper drivers boards plug into and have a go at writing a gcode interpreter. An 8 bit controller running at 16 Mhz should be plenty capable of handling 5 steppers.

You could always just get one of the basic nano-based grbl boards. I use a 2 axis one on my laser engraver. No LCD or control box. No SD card. Has to be controlled via PC (I use cnc js on a raspberry pi)

I didn’t know those existed. That’s exactly what I have in mind except I would like to have 5 axis and SD card support.

There’s a version of grbl that will run on a Mega/Ramps stack that will manage 5 motor drivers and which will support the dual endstop configuration.

I believe the CNC shields that ride on the Uno are limited to 4 drivers due to a shortage of pins on the Uno. They also share a single pin for each of the 3 axes limit switches (i.e. Z min and Z max are really the same pin, same for X and Y). My older CNC Shield (a Chinese copy of the Protoneer v3.00) has space for 4 drivers, but the 4th can be a set up as a clone of any of the first three by default. Here again, with some juggling of pin configurations I think you can get a true 4th axis, but I haven’t futzed that for my applications. I’ll be running my MPCNC X and Y axes with series motor wiring, so 3 axis is plenty for my needs.

I also plan to use CNCjs from the V1Pi image, so absence of LCD and SD card are not a loss as far as I’m concerned, but that does require an additional Rasberry Pi.

I know there are Nano-based boards out there, but I’ve never worked with one so I’m not familiar with their limitations.

Exactly. Everyone has their own idea of what one exception they would like. Marlin supports a ton of boards, and there are a bunch of hardware manufacturers targeting it with new fancy boards. It also supports a ton of features.

I’ve bounced around between the two (grbl and marlin) and I like them both. Marlin supports screens, and does mesh leveling (which I am going to try on my LR someday), and it is the same firmware I use on my printers, so I know it pretty well. Ryan was the one to add dual X and Y to Marlin (for the MPCNC). I don’t think grbl is as easy to get rare features into, which is why the main codebase is really just for one board, and doesn’t have many features.

I’m currently running the grbl esp32 board on my Low Rider, and it works pretty well. I need to get my laser diode on there to try it out before I swap the controller again. Configuring firmware is kind of a habit of mine, I guess.

Just when I think I got the right idea for table/enclosure I see this. I really like that enclosure. Great job!