Well… yes and no. But more like… no ![]()

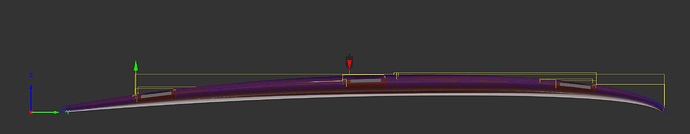

It all depends on the shape of the board and how you position the board in block of foam. Normally you want the board to fit tightly in the smallest possible block of foam to minimise cutting time and also wasted material. So you will probably end up positioning the model like this:

This board is 98mm thick and I think my required Z travel for cutting the bottom side is also around 98mm (for the tail and nose sections). This is because the nose and tail of the board are very thin and I also use CNC to shape the rails. So for this type of board, your max Z travel is also the max thickness of the board.

A wing foil board and e-foil board will have a different shape and will generally be a lot thicker so you will not need as much Z amplitude to cut one side. But still I wouldn’t expect to be cutting 250mm boards on a machine that has 125mm Z axis… unless your boards are going to be completely flat ![]()