I finished my build recently, total nightmare tbh, lots of mistakes made, but thought I’d got there in the end. I managed to cut pieces from a sheet without any issues. Basically had a day of cutting which was fine.

Today I had some free time so figured I’d cut some more things, a continuation of the same pieces from where I left off, but from a new sheet.

The Y travel on one side got stuck/chattery, slow, I don’t even know, it just didn’t keep up with the other side.

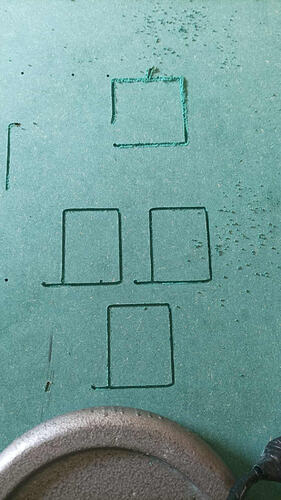

Stopped, re-homed, checked belts, grub screws, aircut was fine, tried cutting a square as a test. Then the X travel jammed and stuttered. I’m like.. wtf. How is Y fine but X not?

Squares looking like this, basically alternating between X and Y travel being good/bad:

Remove router, replaced endmill with a new one. Worked fine for a test square. Oh, it was just the endmill? Maybe I put it in loose, maybe it was dull.. seems ok now, lets try.

Loaded up my gcode, it started, ran about 3 cuts then the Y travel messed up again. Re-homed. Move Y+100, one side stuck, Twisted gantry.

JFC. What is the problem here? Re-home. Check belts. Check movement with my hand. Something else is stuck, oh it’s the stupid endswitch lever gone past the screw heads, now the endswitch is twisted and jammed inside the Y side.

I’m ranting here but basically I am so close to just giving up, it’s been endless troubleshooting and problems.

Update:

Now I’ve taken off the side for the gazillionth time and checked everything, grub screws are tight, pulleys fine, endstop replaced - tomorrow I will re-measure, re-square and run through all the checks again and test cuts again.

I still don’t even know what caused the problem here, I’m just lost.

Aircuts are fine. Under load, travel Y direction one side just jams/skips/I don’t know.

Could this have been caused by the endstop lever being jammed inside (maybe before I started cutting and noticing all the problems) and thus the gantry not being straight when cutting? It not being square basically, after Y home. Would that cause missed steps on the one side or travel problems when the endmill is in the wood/there’s load?

3mm doc, 1/8” 1F endmill, 20mm/s for reference - this cut fine previously.

Any ideas?