Are you going to have a printed option without yz?

I already ordered them with the hardware kit.

No but you can send me a message with your new order number when they are available and I will take it out/credit you.

From here on out this sort of thing probably won’t happen.

Ok now that everything has settled down and everyone is printing or building… Ryan has to come out with something else crazy cool while we’re relaxing at night so we have something to talk about or do haha

Question mainly for beta users/people who have already printed and assembled their LR4s. What is the max height of the machine when its at its highest Z point? I am working on redesigning my LR3 enclosure for my LR4 build, and was wondering if the overall height is similar or not. That is, the height of the actual machine, not usable cutting area

Based on my virtual mockup, I think from the bottom of the 608 bearing roller wheel to the top of the core is something like 317.7 mm, but the top of the router will stick out something like 16-20mm more, and then comes the question of if you have any dust hoses doing something above all that.

Let the man sleep!!

Do You think PETG tool mount is better for makita router?

Regarding Kobalt router availability:

I visited a local Lowes a couple of months ago and, although they did not show on their in-stock inventory, they had four of the Kobalts sitting on their overhead shelf (overflow inventory area?).

I spoke to a manager and was able to purchase all four at $50 each.

OK, first…Good Morning and Happy Sunday!

This is a dumb question. but with all the filament, printer skew calibration, and other printer settings, I’d hate to make this assumption and be wrong…

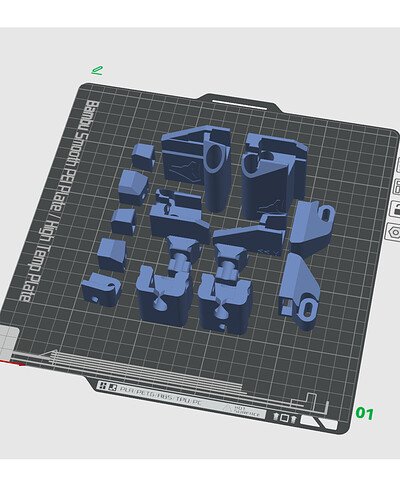

As long as I keep the default orientation, there should be nothing wrong with grouping similar infill parts on the same build plate, correct?

correct

Be careful if you use certain slicers as they will reorient parts.

Think Ryan does, noticed the LR4 printed parts kit comes with PETG router mounts for heat resistance. Make sure you’re happy with layer adhesion, infill and extrusion so you have a good solid reliable support for the router.

Nice! Will look up next time at Lowes…

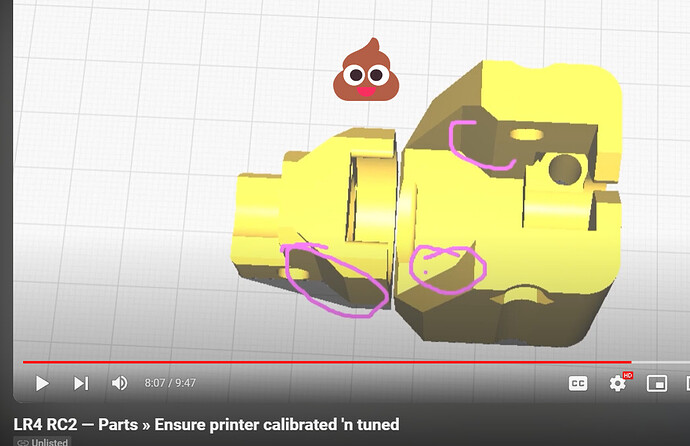

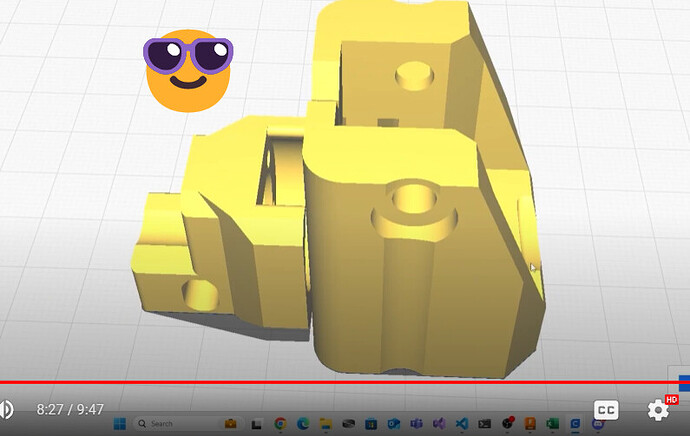

Yep, think Ryan exports parts in correct orientation for printing. But, if wanting to batch multiple parts, then, for any parts that will mate with other parts, consider orientating the same way for better fit just incase your well calibrated printer is slightly off. Also, consider orientating mating surfaces to face away from other surfaces, this’ll help avoid stringing that could interfere with mating. So, don’t do this…

Instead, consider layout more like…

Nope. You can get them a lot closer to save time and increase print quality. Grouping similar heights helps in the same way.

You can easily increase infill on any part, or if you are feeling really fancy your slicer does allow for each part to have different infill percentages and most other settings as well.

Thanks, Ryan!

I’ll move them closer, I believe everything on this plate should be at 30% infill …

@vicious1 I love so much the hardstop configuration with two limit switches connected in series on each axis! This design is almost perfect! I miss only the external covers for YZ Plates😆

The further I go into the built, the more I love Your work and the attention into details!

RIGHT!!! Brilliant design work and execution! Amazing, Ryan!!

If someone is interested I prepared a bambu studio project with multiple beds, divided by color, and each part with its own infill. I can share it

They are not wires in series. Each is independent.

We have some, Peter Plates since he made the first ones, and really helped inspire the overall design of this entire LR4. @bitingmidge I need to add your role in this to the Docs, my apologies!

Thank you all very much, I originally half-assed a lot of it, the beta team would not allow it so the credit goes to them!

Yeah, eff that phillet… ![]() Worst part of the whole build.

Worst part of the whole build. ![]()