Okay, I’m using the file MKS_DLC32_v21_laser.yaml as a reference to create my own file.

1- I make a copy: MKS_DLC328v21_Laser_Plotter.yaml

2- I try to make the necessary modifications block by block

a)

board: MKS-DLC32 V2.1

name: eSloch Laser_Plotter

meta: eSloch 17/01/2024

Doesn’t it look nicer like this?

b)

kinematics:

Cartesian:

I don’t modify … apparently, that’s my situation.

c)

stepping:

engine: I2S_STATIC

idle_ms: 255

pulse_us: 4

dir_delay_us: 1

disable_delay_us: 0

I think the only thing to change is the ‘idle_ms.’ If I understood correctly, a value of 255 implies that the motors are always powered, which is better for precision in movements.

I don’t know about the others. I believe they are fine and shouldn’t be modified, even if I don’t fully understand them.

d) The serious stuff begins here:

axes:

shared_stepper_disable_pin: I2SO.0

x:

steps_per_mm: 100

max_rate_mm_per_min: 16000

acceleration_mm_per_sec2: 1500

max_travel_mm: 895

soft_limits: true

homing:

cycle: 0

positive_direction: false

mpos_mm: 0.000

feed_mm_per_min: 300.000

seek_mm_per_min: 8000.000

settle_ms: 500

seek_scaler: 1.100

feed_scaler: 1.100

motor0:

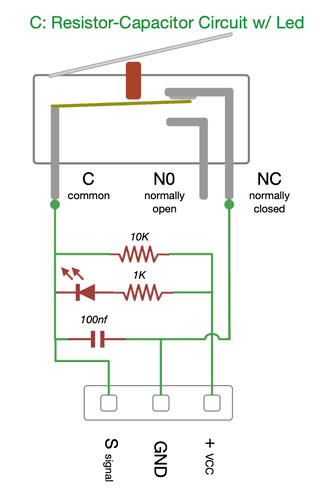

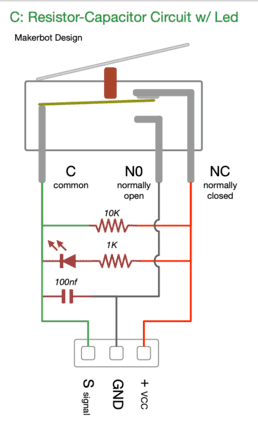

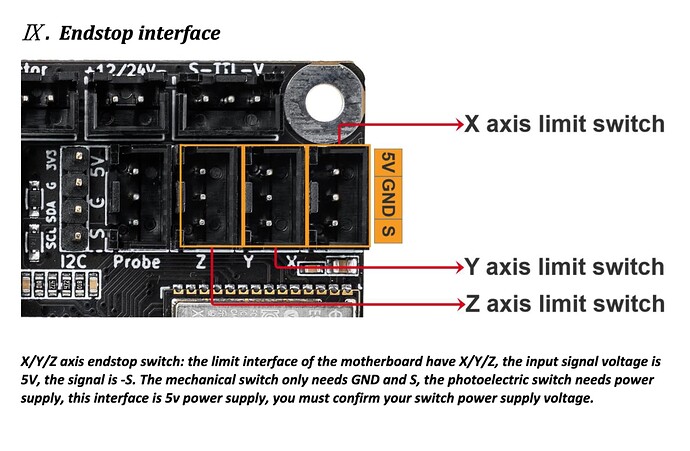

limit_neg_pin: gpio.36:low

hard_limits: false

pulloff_mm: 2.000

stepstick:

step_pin: I2SO.1

direction_pin: I2SO.2:low

So, the “steps_per_mm”… how should I define it? … Also, the “max_rate_mm_per_min” and “acceleration_mm_per_sec2”?

I’ll calculate the “max_travel_mm” precisely once I finish the CNC design (in progress, almost done).

For “soft_limits,” I set it to “true” since I only have two mechanical limits on my CNC. I think it’s interesting.

Now, the “homing” section: is a cycle of 0 correct? What about the other parameters? Are these values correct to start with, or could they potentially harm my machine?

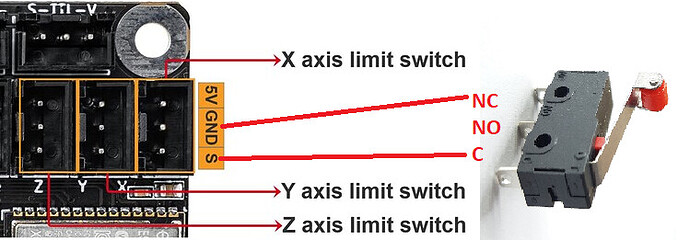

In the “motor0” section, for “limit_neg_pin,” is it “gpio.36” or “gpio.36:low”? And for “hard_limits,” is it false or true?

Alright, my head is already aching. I need to understand this in more detail.

I noticed in some config files there’s an indication of the stepper used. In my case, it’s TMC2208. Should I specify this somewhere in this section?