New guy around.

I’m in Edmonton, AB Canada. I have designed and built a few 3D printers for myself, and was looking at designing a CNC router as well when I found the MPCNC.

I have designed and built a few 3D printers. I started with an I3 clone kit several years ago that was terrible, and now have a couple of decent ones. One prints exclusively ABS and one PETg. It’s been long time since I’ve bought a spool of PLA. I think I have a couple of half spools in dry storage, but I would certainly need to buy at least a couple of new ones in order to print all of the parts. It is of course less expensive than buying the parts, but I am considering just buying printed parts. (If any parts end up bright yellow in my finished build, it’s probably because I broke something and had to reprint.) I would consider printing in PETg, as this is my most used medium, but want a robust building area, and rigidity is indeed key.

I am an avid DIYer, I build DIY audio electronics, analog signal processors and amplifiers and the like. I have built a couple of DIY video projectors, and am working on one now, for which a CNC router would be extremely useful. I built the engine in my car up from a bare block, and have some ideas for parts that I would like to be able to mill from aluminum, including some instrumentation panels. (I 3D printed a panel, but it doesn’t do well in the summer sun, of course.)

I have very limited experience in CAD. I am trying to learn Fusion360, but have done most of my work in Tinkercad. I believe that I have stretched that tool to its limits, but have managed to do some good work with it.

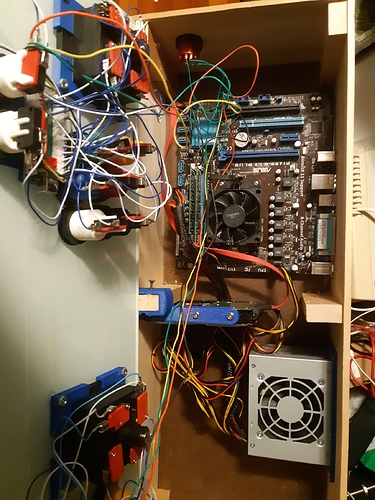

I have several electronics boards around from experiments and some tinkering, including a spare Duet WiFi, which I would like to use. I am reasonably comfortable with the firmware to configure the drivers and axes. I’ve seen topics where people intended to use a Duet, but haven’t seen any completed builds that way.

What will probably take me longer is figuring out the chain from drawing to Gcode. I’ve only looked very briefly into this. I modified an old 3D printer with a 50mm spindle, and have so far managed not much of much for getting usable Gcode. I’m sure that once I catch on, I’ll be okay with it.

I’m sure that I’ll have questions once I start building, but for now…

So… Some good primers for Fusion360? What kind of path calculators should I be looking at to be able to do some reasonable milling?