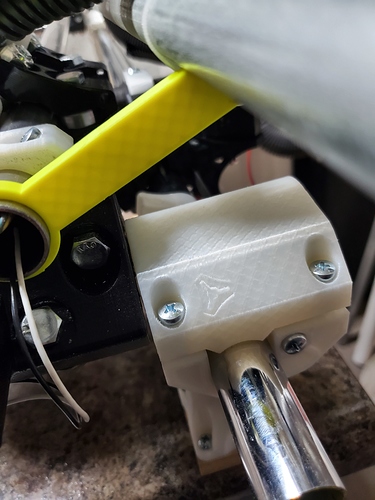

Guess I never updated that, lol. Got the dual endstops on!

Also got tired of cutting into the spoilboard in one corner and not even through the stock towards the middle. Left me with a lot of trimming and sanding to do, and wifey has started selling some of the stuff I make, so ain’t nobody got time for that! Some places it was a good 1/16in or so.

I went back and forth on surfacing the spoilboard. I read every thread I could find here. I think I have a handle on the issues it MAY introduce. And it seemed kinda like a lot of cutting to solve this one problem. Indeed, I spent about a half hour creating the toolpaths (took 3 go’s to get it just right) and probably 6 hours cutting (multiple depths/attempts, several starts on each of the 2nd and 3 attempts). In the end, i took off a lot more than I wanted to. BUT…

I got the dreaded ridges with my 3/4in router bit. Primo core, and I’m mostly sure my printer prints square in the z. I did run the V1 test after I printed my core (which is when it was released). My legs are all short enough that the corner pieces were all collapsed and touching.

But I figured the old desk I’m using is slightly wonky. I know it is for sure. Weighs about 200 pounds and I rolled it home down the street on end using a hand truck. Then I moved it next door (where I’m now renting) on a couple dollies. And the primo feet are mounted on top of mdf. And I glued/screwed a demoed laminate countertop onto it to get more area. So, lots of things to go wrong.

I tweaked the legs a bunch during the second run bendy it was the only way I could think of to tilt the core, and a few times before the last run.

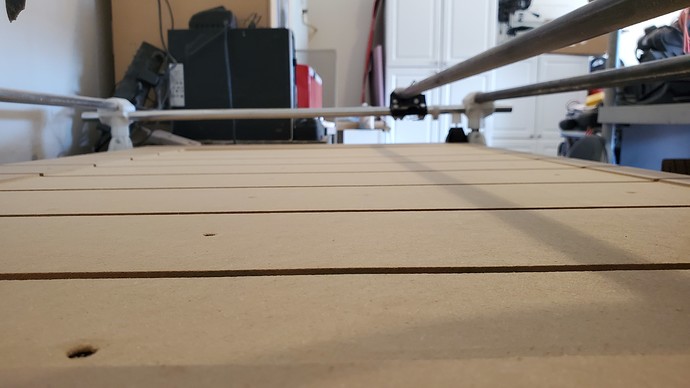

Ended up with this :

You can see the front right leg there on the right. Came up a bit. The front left is out of view, but also to the right. It came up about half that much. Both rear legs on the left remained unadjusted.

I don’t really understand how anything I did during construction could bring the leg mountings that far out of the plane, but thinking about it, 3 points define the plane and maybe that corner is just too low relative to the other 3. Actually, that makes a lot of sense. Probably could have shimmed under the desk right there. I’ll have to go see if it’s missing the foot.

Now, 1) when I send it to zero anywhere on the surface, it’s actually at zero, so that’s good and 2)since there are no ridges, I presume the tool is perpendicular to the surface in both directions. If 1 and 2 are actually true, then I really don’t care about anything else, I think.

Since the work area is so large (2x4) I only have one or two jobs that tile, and those aren’t through cuts, so I’ll raise them up to cut. Everything else fits easily (so far). I’ll probably lift up anything that through cuts on some mdf. The stuff I’ve measured all seems to be +/- 0.02in.