Possible also just bad connections after being moved

I’ve checked all the connections are seated properly, but it’s worth rechecking. Thanks.

I had this happen with my laser about 5 years ago and dont remember the cause . Gcode error or sender or noise in line its skipping code line and getting shot off but resumes the next line in correct spot not skipping steps just misdirected I dont remember the cause though

Does it happen randomly or same spot? It is not going to x or y 0 is it ?

Different spots when I run the same job, heads down to Y0, then back up to resume the job.

Less frequently it goes to X0. It seems to happen once or twice in each run.

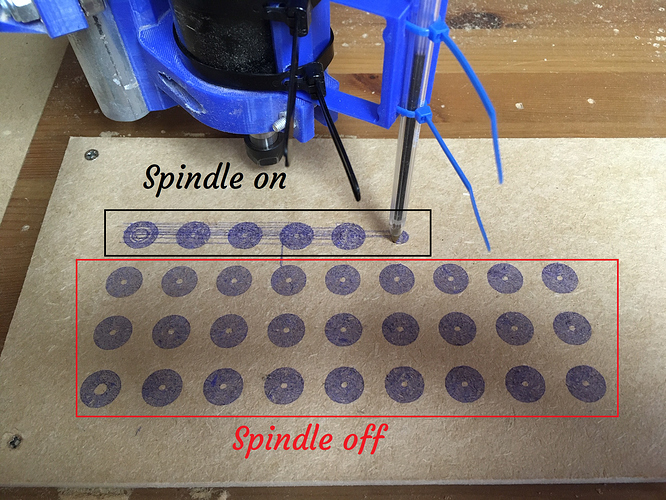

I have pinned down the culprit. It’s my spindle, or the powering of it anyway. A ran a job with a pen crudely attached to the spindle, chose a long one (27 hole array I have failed to make in wood ten times now) to try and give me the best chance of seeing my intermittent fault, and ran it with and without the spindle powered up.

So I’m guessing it’s something like the routing of the power cable (too close to the board?), possibly static (I’ve earthed everything except the spindle body), I’m really not sure. Anyway, I’m mighty relieved, I have a way forward. Thanks for your help all. I will hopefully stop turning proto-signs into definitive and bloody expensive firewood.

Although of course I’ve not actually solved this yet, so any help would be gratefully received!

The power supply for the spindle can be the issue, too close to your board, or try plugging it into a separate circuit.

Thanks Ryan, I can easily reroute the cable so it’s not near the board, but using a different circuit is not possible unless I buy a generator (I’m in a shed at the bottom of the garden). What I would really like is to understand and define precisely the reasons for this problem, but I suspect the electrical explanation is too complicated for me!

It could be electrical interference from the cord affecting the lcd cables. Do you have the long LCD cables? If so, you might try shorter ones. Or you might try shielding them, and grounding the shield.

The other thing it could be is a bad ground. If enough current is going through the spindle. It is leaving the shed on the negative terminal. If it isn’t leaving fast enough, because the connection doesn’t have a ground, or the connection is through a long, small cable, it can affect the level of ground, which can affect the digital logic. I hope this isn’t the case, because I would expect it to cycle power before making mistakes.

Thanks @jeffeb3, I will rearrange to distance other power supplies from the LCD and board, and I suspect I will also shield them. I do have the long LCD cables, so I do need to take precautions. As far as grounding, I am at the end of a reasonably long cable, but suspected this might be a problem so I created a new ground/earth last week with a 6 foot stake. I’ve almost grounded everything, just the spindle case left.

Thanks for your help.

If the outlets in the shed are grounded/earthed to the (I assume) house supply, then you may have created a ground loop by establishing a new ground/earth at the shed. Check for any voltage between your new ground and the original/building ground.

Thanks Tom, I hadn’t thought of that, by which I mean I didn’t even know that was a thing. Makes sense though.

I got round to earthing the spindle case. When powered up but not spinning, there are 200-250mv at 4amps running from it to my newly created earth. That’s not normal is it? When I start it spinning, the voltage drops to 30-40mV then seems to slowly creep back up to 100mV or so, then returns to 250mV when I stop it spinning. Current always at 4 amps or so. Spindle incorrectly wired maybe? Or just a piece of crap?

My electrical knowledge doesn’t go much further than ideal electronics at school, I’ve never analysed ‘real’ electronics.

How are you measuring the 250mV? Depending on where that is, it may be nothing.

I think you can twist the lcd wires to reduce the impact of emi as well. I am trying to decide if they are differential signals or not… Won’t hurt it.

I soldered a connection from the case of the spindle to an earth lead, and stuck my multimeter between it and earth, just out of curiosity really. I have no experience to put the measurement in context though, so it could well be nothing, as you suggest. The LCD is now about 4 feet away from the spindle power supply, but I’m still having problems with errant movements. I know they are caused by having the spindle running, but it has worked with the CNC perfectly in the past, so I’m puzzled. One way or another I’ll work it out, but it’ll come to me in the middle of the night in 2-3 weeks

Thanks for your input Jeffe, it’s much appreciated.

I seem to have solved my problem, I have run three jobs which have completed perfectly. However, there was no single thing I can ascribe this to, and I have a strong suspicion it’s a confluence of two issues.

- I physically separated all cables so none were close and none were co-linear

- I removed all my earthing cables (these made things worse, possibly through the mechanism @ttraband warned about)

- I reformatted (the slow way, the fast way made no difference) my SD card

This made things run much better with just the odd blip. Then yesterday I moved an old laptop into the shed and installed Repetier Host, attached to my board and removed the LCD Display from things completely. Three jobs ran perfectly. Yes!

I’m slightly uncomfortable with a dual cause for all this (spindle power interfering with data from card to board, despite their physical separation), but it seems the only reasonable explanation.

At first I thought this comment from @jeffeb3 was rather unhelpful “The machine is dumb”, but actually it is a fact that I needed to use in all my problem solving. I will not forget this.

Thank you all for your patience, I’ve learnt a lot. I have also learnt that this machine means rather a lot to me which is either weird, or a huge accolade, depending on how you look at it.

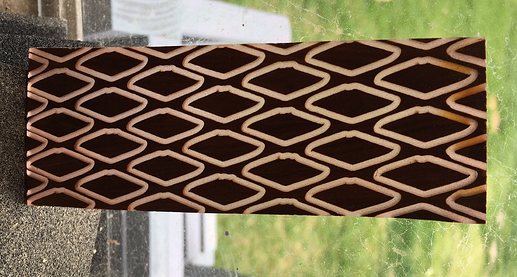

Lastly, I finished off a little practise sample: ignore the imperfections in the shapes, that was my poor execution of the cuts, but I was wondering about creating floating shapes in resin by cutting not quite through the material, filling with resin and then planing of the back. Works well, and I think this could be interesting. No ideas what I could use it for yet though.

Haha. I like that sentiment too. Barry has a sign in his barn that says, “This machine has no brain, use yours”. I also like this silly fake sms message I made for the docs:

https://docs.v1engineering.com/learn/gcode/

Glad it is working for you.

That resin idea is great. There was another user making knife handles with a similar technique (sorry, I forgot the name). I imagine you could make nice pen blanks too. Or, at the scale you have, maybe a lighter color resin could be used for a lamp or wall sconce.

Thanks Jeff, I will be making an appropriate sign soon to that effect!

The resin thing: I just realised it’s not obvious what is wood and what is resin. The parts cut from wood are dark brown, the resin is the light bit inbetween. Now all I can see is floating, hollow white diamond shapes in a sea of brown resin

Oh, now I see it. That actually makes more sense.