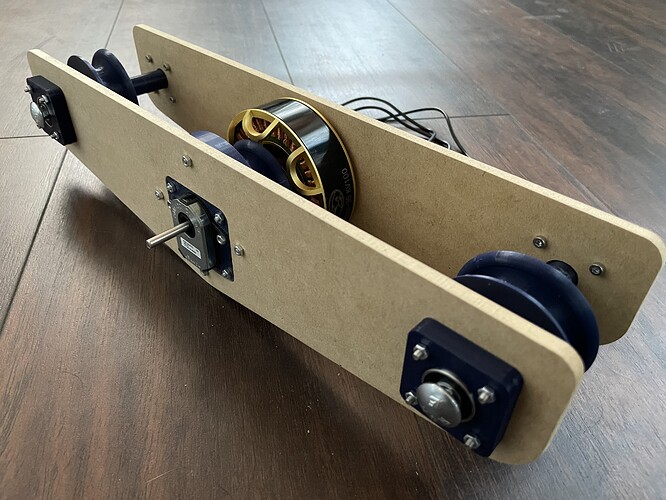

This is a prototype trolley system that drives itself along a cable stretched between two points. It’s designed to hang a commercial gimbal system and camera below the gantry in order to create cinematic camera movement over areas that would be challenging to do so with conventional methods.

The CNC cut parts are simply the two side plates. However, this is precisely what I built the LR3 for - to do precision subtractive manufacturing to complement additive manufacturing using 3d printing.

The entire prototype is designed in Fusion 360. The CNC gives me that sub mm accuracy to drill and cut the plate material so the 3d printed parts are perfectly aligned and fit.

Some parts like the 3d printed encoder plate fit snugly into the plate cutout to provide radial support. The outer bearing blocks will eventually sit in a recess to give sheer relief from the mechanical fasteners.

The axels are heavily influenced by the mpcnc design by using 5/16 bolt hardware through 608 bearings held in place with 3D printed material. The sheet cut material gives strength and practicality across the larger spans.

This is not its final form. It’s a prototype to demonstrate functionality and uncover any necessary mechanical changes. It will be driven by an odrive controller and hang a zhiyun gimbal carrying a BlackMagic camera.