Warning: This is NOT rocket science. If you don’t need this tool, you just don’t need it.

Functional squareness is pretty much requirement for any of the various versions of the MPCNC–Burley, Primo, LR2, LR3, etc. When you rout a circle, you want it to be a circle, not an ellipse.

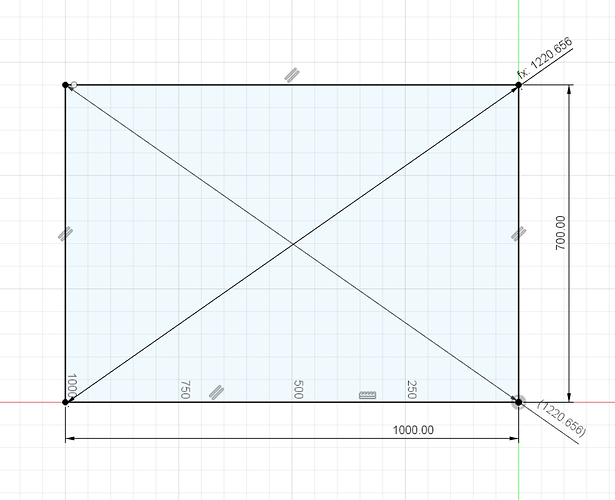

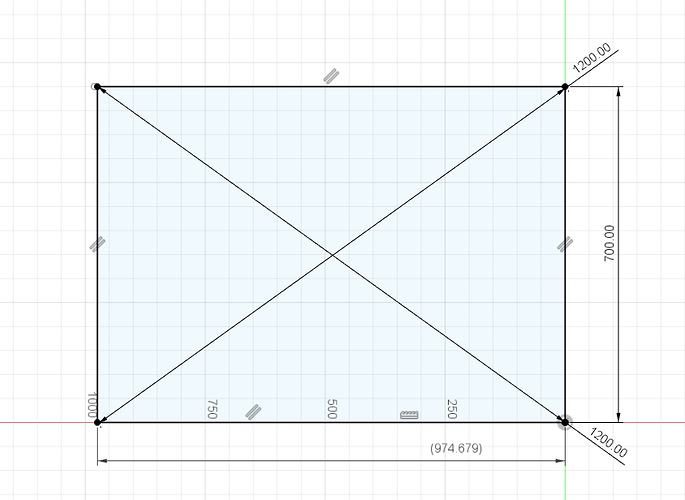

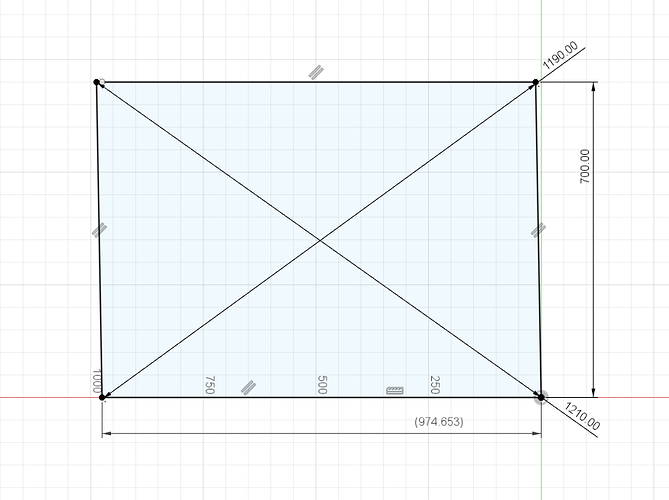

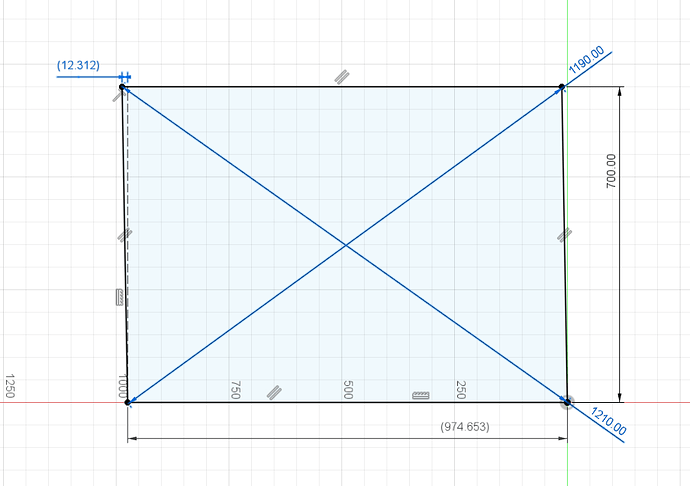

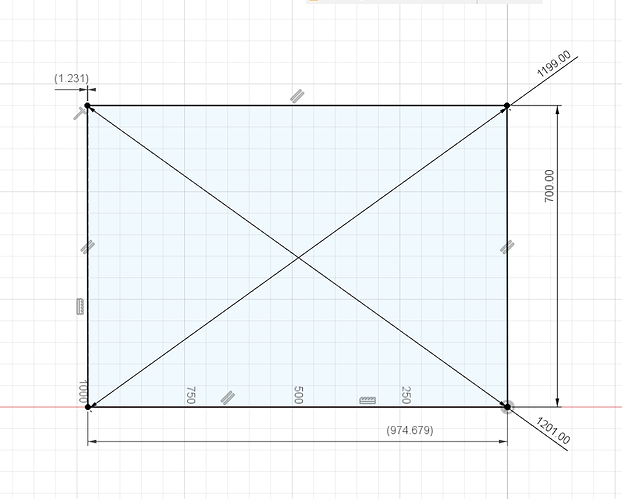

One of the key elements to confirming that your CNC router is operating correctly is the measurement of the diagonals of rectangular patterns. If the machining is square, the diagonals will be identical. For those using dual endstops on x or y, the usual method is to draw something and measure the diagonals, followed by a correction and repeating the process.

For large tables, I have found this difficult to do using a tape measure when I don’t have a helper. While there are various ways to do it, I wanted something that is quick, easy, adjustable and accurate. To that end, I found a yardstick-based trammel point design on Printables ( Printables ), and did a simple re-mix so that the pivots now have a pointer that has a spherical shape, 1/8" in my case.

By using a 1/8" ball nose router bit, and routing shallow dimples at the corners of what is supposed to be a rectangle, you can check the diagonals by yourself since the tip of the pivot forms a sort of kinematic connection to the routed dimple. And, since the beam can be a simple wooden yard stick, the fabrication is very low cost. Or, if you need a longer beam, it’s simple to fabricate. Of course, you could still use a nail and mark the corners with a smaller probe or with a pen. But, with no assistance, I don’t find those methods as accurate.

Some pics may help.

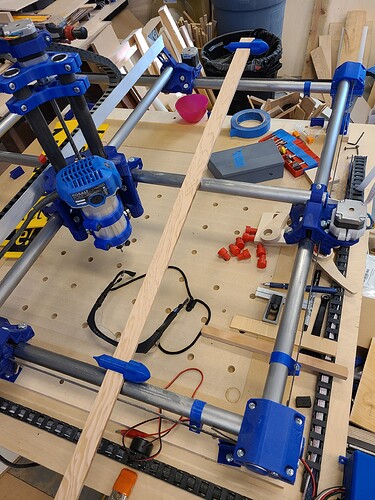

Overview of Story Trammel (ignore the clutter)

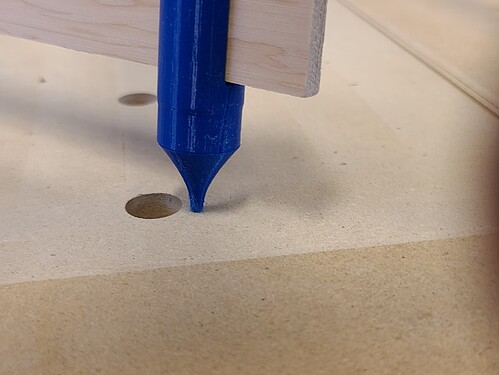

Shows the pivot and the dimple (circled). This was about 1mm deep.

The pivot point placed into the dimple. There is no detectable “slop”, which suggests the accuracy must be better than 0.1mm. Maybe a lot better.

I actually got lucky and after only 1 adjustment of the dual endstop, had a perfect fit on both diagonals. I think #Primo.new is ready to go…

Here’s a link to my remixed pivot ends.

https://www.printables.com/model/880548-story-stick-version-of-yardstick-trammel