Cut the tubes and beginning the prints. Need to order parts soon

How high do people make the feet for their MPCNC? Is the 70mm minimum height (57mm feet) recommended by the Jcalc too short?

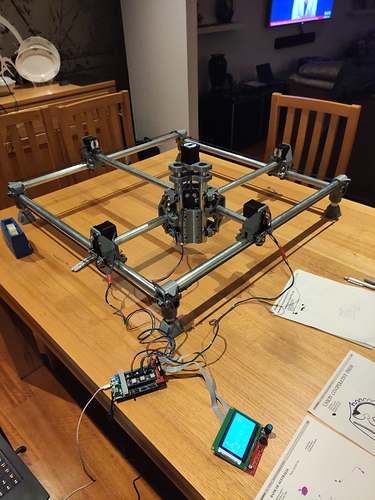

I’m no expert but I made mine the minimum height for extra rigidity. My cut area is 600mmx900mm. So far it is solid, but at some time in the future I will replace those tubes to get a little more z height. I just started experimenting with cutting reliefs and realized how limiting a minimum z height is.

If you plan on cutting hardwoods or aluminum shorter legs are recommended.

Jake

Great project. I’m in the early stages of investigating to build one too. Which supplier did you use for the tubing? I’m looking for stainless here in QLD, but could only find one supplier in WA, but that one was very expensive. Did you go for galv steel or stainless?

Just got the Metal Mate galvanised steel ones from Bunnings like Teaching Tech did. Then I just cut with the drop saw and bench grinded and filed the ends to make them relatively smooth. Hope you weren’t affected by the floods bud. Stay safe

Little update: I’m about halfway done printing the parts and have just placed an order for all nuts and bolts from Accu Group. Came to around $80 AUD for all nuts and bolts shipped to Australia from UK. Was about $50 cheaper than AliExpress and they had it all in one place. Final Price for the whole MPCNC is $420 ( I know ) AUD

Does it matter if some of the bolts are full thread, or do some need to be half thread?

nope.

Most of the bolts are only going to just barely engage the nylon, and even so, the bearings should fit over the threads just fine. I’m sure there’s some micro-optimization to be had by having full-shank inside the bearings, but I doubt 99.9%+ of MPCNC users would be able to measure, much less care about it. If anything, it might decrease the life of the bearing by some amount. Much like living on a continent where everything is trying to kill you…

Stay safe!

All prints done (unless I accidentally missed a part, which I’ll soon find out). Going to order my electronics now. Super psyched.

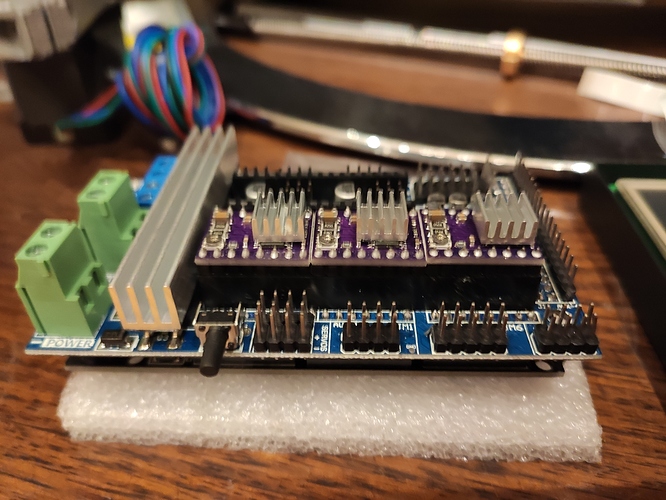

Electronics ordered. Final build cost is $380 AUD shipped for electronics and hardware, $80 for nuts and bolts, and $40 for printed parts. I went with an 800W spindle in the end, Ramps 1.6, LCD Display, no endstops for now until I learn the machine how it is, and a 12V 6A power supply.

So with my 800w spindle, it comes with all the collets for attaching the (end mills?) I think. Can someone please recommend a good kit with some different types I could try?

Would these sets work?

https://www.amazon.com.au/4-Flute-0-08-0-47-Straight-Aluminum-Titanium/dp/B07DQL66VF/ref=asc_df_B07DQL66VF/?tag=googleshopmob-22&linkCode=df0&hvadid=341745064557&hvpos=1o1&hvnetw=g&hvrand=7378254519695635495&hvpone=&hvptwo=&hvqmt=&hvdev=m&hvdvcmdl=&hvlocint=&hvlocphy=1000567&hvtargid=pla-474624134793&psc=1

https://www.amazon.com.au/mcwdoit-Cutting-Milling-Including-Engraving/dp/B07ZCN4CLR/ref=asc_df_B07ZCN4CLR/?tag=googleshopmob-22&linkCode=df0&hvadid=408012334022&hvpos=1o2&hvnetw=g&hvrand=7378254519695635495&hvpone=&hvptwo=&hvqmt=&hvdev=m&hvdvcmdl=&hvlocint=&hvlocphy=1000567&hvtargid=pla-860242062635&psc=1

Single flute upcut bit is recommended to start. It evacuates chips better for a pocket. Two flutes change the whole dynamic of cutting load. I’ve had good success with mine (single flutes) that I got from Ryan. I got a few of them and have pretty much stuck with them, other than the 60 degree vbit. Haven’t tried the ball mill yet.

Sent some cash Ryan’s way. Still waiting on an LED display to arrive and then I’ll hopefully be building these school holidays.

Looks great!

Any tips on what to do with the Z-axis cable? I’ve also ordered my end mills just now. Got single flute as suggested, 3.175mm shank and some 4mm shank just in case one doesn’t work. How does length play a role in these? Cheers