I think that I understand this issue, but I wanted to post here just in case someone has a solution that I have not yet found.

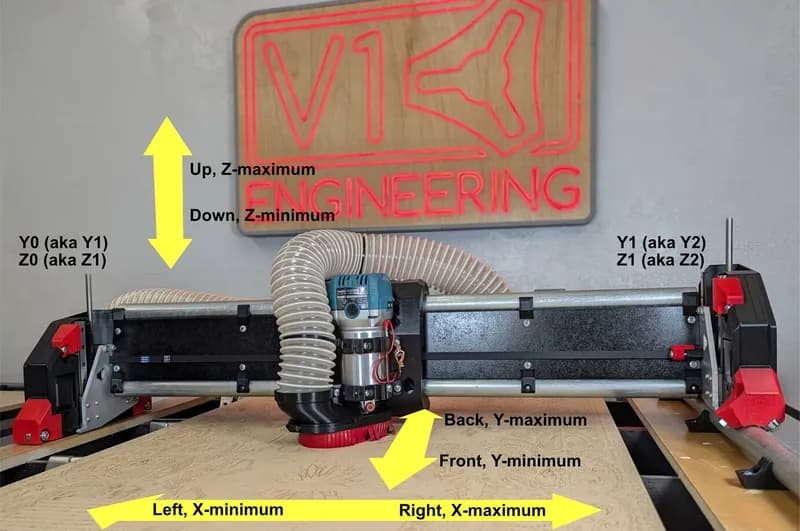

I’m about to embark on a project in which a bunch of pieces will be cut from 18mm baltic birch plywood using the LR4. I’ve decided to try to use the “Badger” bit which is a 1/8" diameter rough cutting bit that supposedly allows for more aggressive cutting than is usually possible. Initial testing suggests that this may, in fact, be the case.

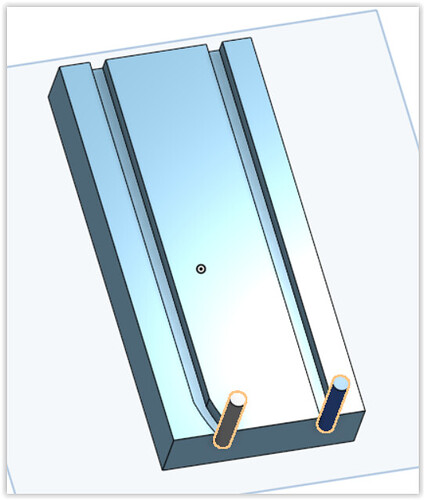

However, I’ve run into a problem during the testing. In particular, with DOC of say 3mm, the whole gantry shifts to the left as the bit enters the plywood from the edge. It kinda looks like this:

The right side is what I want to happen, but the left side is what actually happens. The shift is around 5-10mm. I assume that is occurring because of the rotation of the bit is exerting strong forces causing it to drift to the left.

Also, the toolpath for this test is directly along X, so the shift is in the +Y direction.

I’ve tried a couple of things, including reducing the DOC and slowing the feed rate (which was initially about 1500mm/min I think.) I also tightened the Y belts and increased the current on the y motors since they were running at only about 42° C.

I’ve only done “quick and dirty” testing, but so far, nothing has reliably solved the problem, although reducing the DOC would probably work.

And, just to be clear, it’s definitely the gantry that is moving, not the workpiece.

So, my question is whether someone knows a reliable approach to resolving this that won’t slow down the cutting too much. To cut out all the pieces from this 4’x8’ pattern is going to take 6-8 hours even using very aggressive conditions. I’d like to not extend the time too much.

And, for those interested, here’s the scoop on the “Badger”: