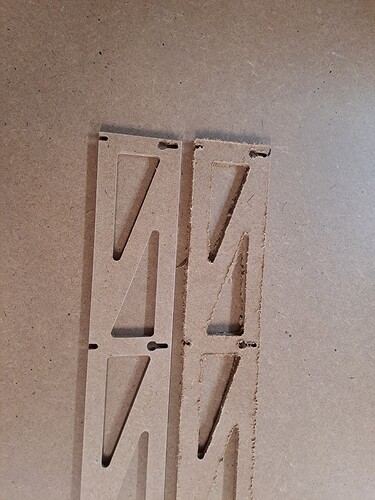

What combination of speeds, feeds, bit, depth of cut, etc. will give a clean cut in 1/8" hardboard? Mine is just tearing like crazy. This is with a 1/8" single O flute upcut bit, speed around 2 on the Makita, feed 762 mm/min, depth 1 mm. Does it matter which side I cut from?

The only way I got anything looking nice in hardboard was to use a downcut bit, and then it depended on if it was down tight to the spoilboard.

I’m thinking of redoing the struts in 1/4" plywood as that should be cleaner and a lot more rigid. I can’t imagine the hardboard adds that much rigidity, it feels practically like cardboard.

It adds a lot. It also should look better. ![]()

More than you would think. Still, the plywood will be better.

I am using 1/4" MDF with a melamine coating. The melamine makes for a pretty good cut edge, though there were still some issues. I’d like to do something with 5.5mm acrylic, but it’s so expensive still.

I might suggest that you look at subfloor material. At the local Agent Orange big box, it’s cheaper than 1/4" plywood. It’s 5mm thickness, so a little thinner but significantly less money.

I had a lot of tear out too. However, just a little bit of sanding knocked that fuzz off.

I started off thinking the same thing you are. I made an X gantry for LR3 using 1/8" hardboard, and then replaced it with 1/4" plywood.

I later found out that Ryan recommends, for the strut plates, use of more rigid materials such as hardboard, OSB, or MDF, all of them preferred over plywood. The 1/8" hardboard may seem flimsy but for its role in this, basically doing the same “skin” type thing that happens on torsion boxes, it works well.

I had saved the first gantry made with hardboard, and I went on to use it to make another LowRider v3 for carrying a plasma cutter.

I got some cheap 2 flute 1/8" straight cut bits and they seem to cut a little cleaner than the upcut. I think with some careful cleanup and installation these will be adequate. I think it’s better to reinstall the screws completely rather than using the keyholes – I damaged my last set of struts by bending them that way.

btw, flipping the hardboard to cut on the other side made no discernible difference in my small test.

what about taping the area where it should cut?

New, sharp downcut or straight bit. Secured stock (double-sided tape or painters tape + super glue). A drum/belt/palm sander. And one of these:

Got myself a random orbital sander, cleaned up the struts carefully and they’re looking pretty decent! Thanks everyone for your help.

I went the harboard route. Yours look to turn out great. Mine did look rough but 320 grit and it cleaned up pretty easy. Like @DougJoseph said, just knock the fuzz off. I used the 1/8" Single Flute Carbide Endmill and happy with the results.