Definitely not as simple as the solder joint, sadly. The tl;dr version is that they’re stuffed and likely not realistically repairable. They’re also designed poorly and will all inevitably fail.

With most LED lighting it’s either a long slow failure over time when the LEDs themselves overheat/age or a rapid failure when the driver goes.

From your description and looking at the LEDs closely, it seems like that’s probably an LED failure. Each string of LEDs has at least one element with some brown/black marks right where the emitter element is:

When they should all look like this:

Usually if it’s a long term overheating failure then the packages and resin fill are more discoloured than that, so I assume these have failed in a relatively short period, run-time wise.

It’s technically possible to repair these by replacing the elements but that’s wildly impractical. Aluminium PCB like that doesn’t like being reworked, you’d want to replace all the LEDs together and the likely overall cost would be more than a new fitting from a known-good supplier. For a single unit with no replacement options, you could potentially do it but you’re still stuck with the fact that these are poorly designed.

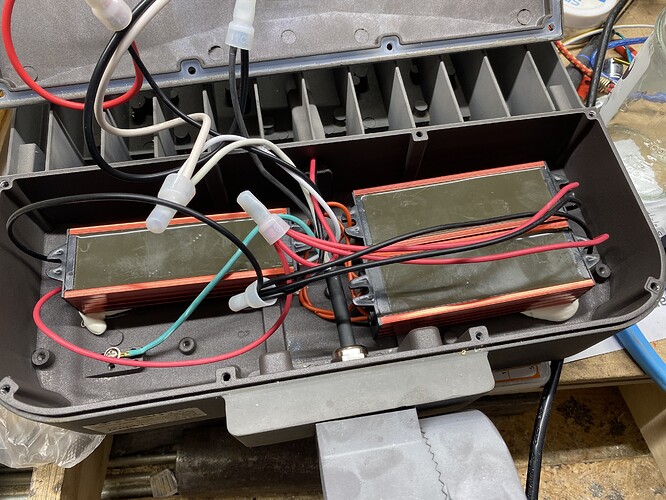

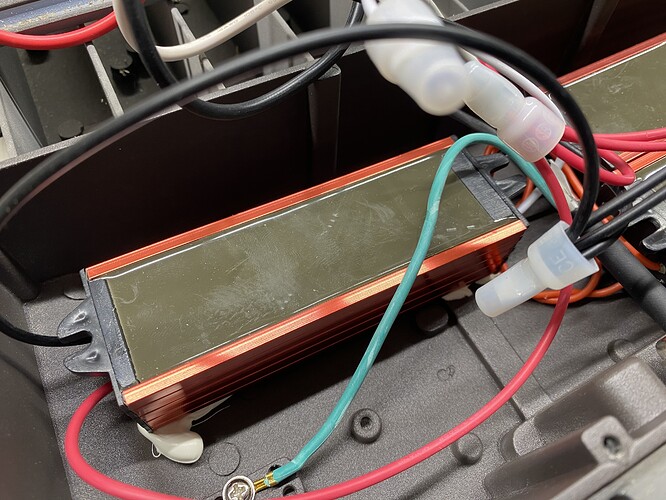

I say poorly designed because this isn’t how you control LEDs effectively. They’re routed as 8 LEDs in series and then 18 strings in parallel. When using LEDs, especially high efficiency white LEDs, their voltage drop depends significantly on the current going through them but also their temperature, age, manufacturing tolerance etc. Typically this isn’t a problem because you either put a resistor in series or you use a constant-current driver.

Putting a resistor in series acts to limit the effect of that voltage swing because in a 12V system you might have 2V on the LED and 10V on the resistor. Even if the LED were 1V or 3V, the current through the resistor wouldn’t change all that much, and it’s the current that’s important. That’s still something that a good design will take into account to avoid issues like differences in indicator brightness when they’re next to each other, for instance. This isn’t normally done in lighting applications because if you’ve got 10V on your resistor and 2V on your LED, you’re wasting 5x as much power in the resistor as heat as you are putting into the LED itself, making it wildly inefficient.

A constant-current driver is the good way to do this. It’s a power supply that instead of putting out a fixed voltage puts out a fixed current. That way if you drive a single string of LEDs from one then you don’t get any variation if the LEDs voltage changes because the current stays the same regardless. The downside of this approach is that it only really works with a single string of LEDs. If you put LEDs in parallel you’re relying on their voltage being matched for them to share current effectively. If it isn’t then the fixed current will still flow, it will just not be balanced, which will cause one string to overheat and drive it further out of balance. That string will eventually fail, go open-circuit and the others will then share the current among fewer strings, eventually overheating and causing them to fail in a domino effect.

The fact that there are multiple strings in parallel and no resistors means that there is no way these LEDs can be controlled effectively enough to last for a long service life.

Sadly, this fitting is garbage and will never last any length of time. LED lighting is one of those things where there simply isn’t a substitute for quality, sadly. It’s very easy to do cheaply and poorly, but remarkably tricky to do right. That leads to a lot of situations where things like this happen, you’ll see a $20 fitting from a box store and then a $50 fitting from a lighting specialist and go ‘pffft, I could replace it twice and still be ahead’… Maybe that works for an occasional use fitting but if it has any amount of hours on it at all, you’ll be replacing the cheap one 10x for the same lifespan.

So, bad news, I’m afraid. Even the ones that are still working are on borrowed time and will not last a significantly longer life.