Tom Traband & Jeffeb3,

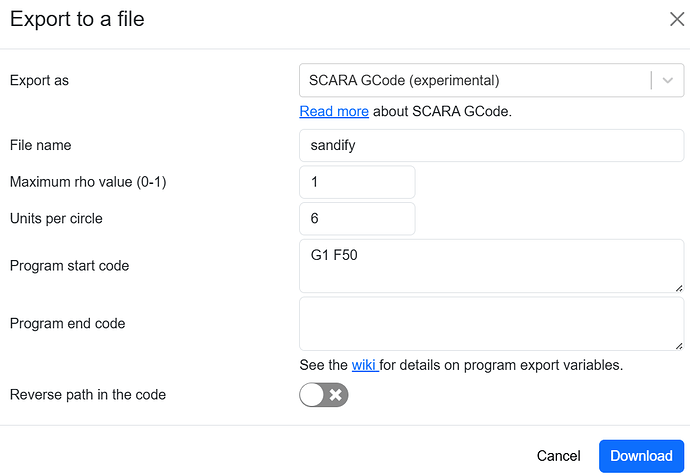

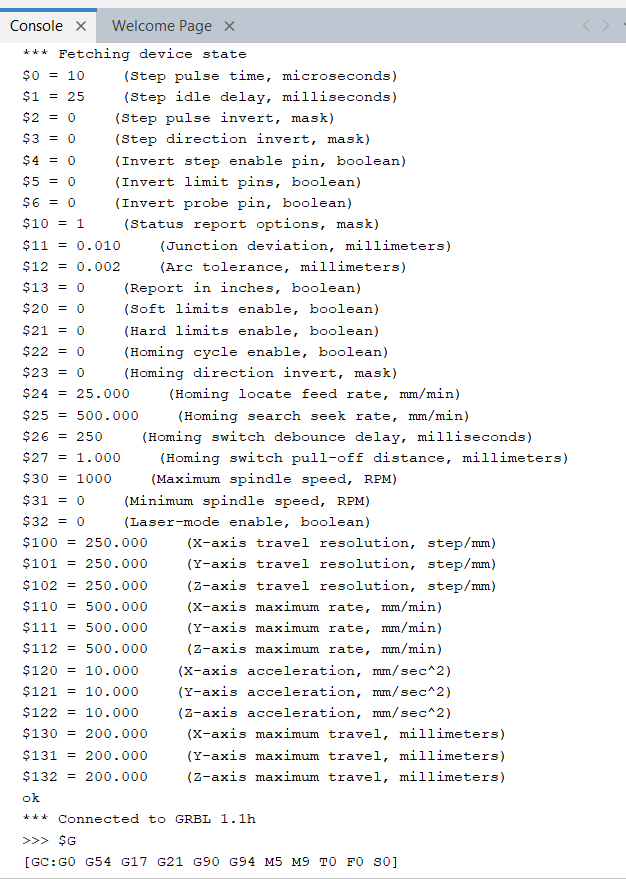

I followed the instructions you gave exactly. But I still couldn’t control the robot properly when I was given a design. If you can, please provide me with a G-code that you know.

to check whether the GRBL parameters I am using are correct or not, I will add that to this message as well.

$0=10 (Step pulse time, microseconds)

$1=25 (Step idle delay, milliseconds)

$2=0 (Step pulse invert, mask)

$3=0 (Step direction invert, mask)

$4=0 (Invert step enable pin, boolean)

$5=0 (Invert limit pins, boolean)

$6=0 (Invert probe pin, boolean)

$10=1 (Status report options, mask)

$11=0.010 (Junction deviation, millimeters)

$12=0.002 (Arc tolerance, millimeters)

$13=0 (Report in inches, boolean)

$20=0 (Soft limits enable, boolean)

$21=0 (Hard limits enable, boolean)

$22=0 (Homing cycle enable, boolean)

$23=0 (Homing direction invert, mask)

$24=25.000 (Homing locate feed rate, mm/min)

$25=500.000 (Homing search seek rate, mm/min)

$26=250 (Homing switch debounce delay, milliseconds)

$27=1.000 (Homing switch pull-off distance, millimeters)

$30=1000 (Maximum spindle speed, RPM)

$31=0 (Minimum spindle speed, RPM)

$32=0 (Laser-mode enable, boolean)

$100=800.000 (X-axis travel resolution, step/mm)

$101=800.000 (Y-axis travel resolution, step/mm)

$102=250.000 (Z-axis travel resolution, step/mm)

$110=100.000 (X-axis maximum rate, mm/min)

$111=100.000 (Y-axis maximum rate, mm/min)

$112=500.000 (Z-axis maximum rate, mm/min)

$120=10.000 (X-axis acceleration, mm/sec^2)

$121=10.000 (Y-axis acceleration, mm/sec^2)

$122=10.000 (Z-axis acceleration, mm/sec^2)

$130=200.000 (X-axis maximum travel, millimeters)

$131=200.000 (Y-axis maximum travel, millimeters)

$132=200.000 (Z-axis maximum travel, millimeters)

ok

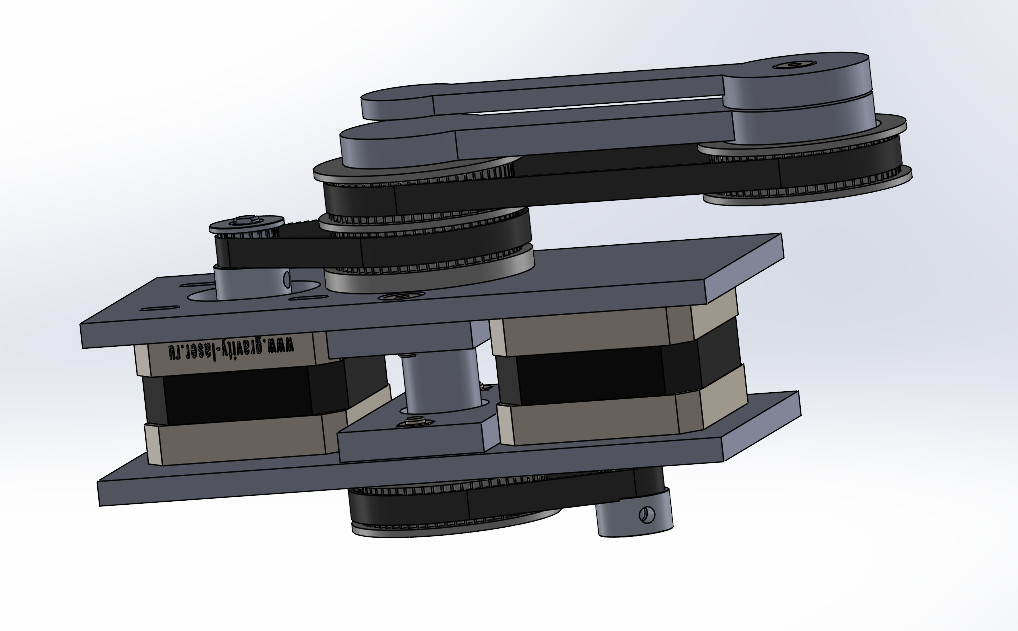

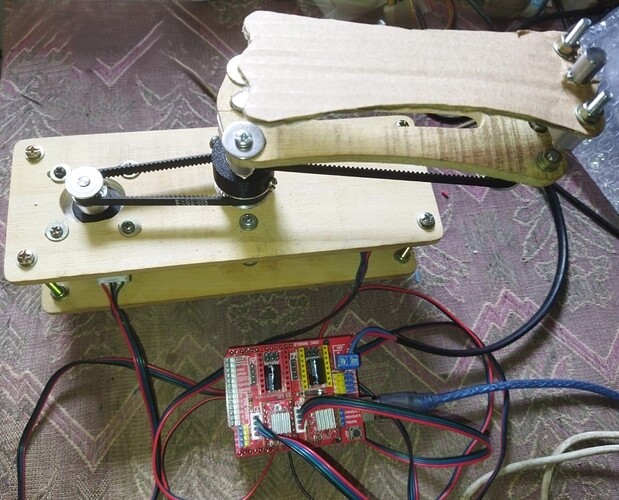

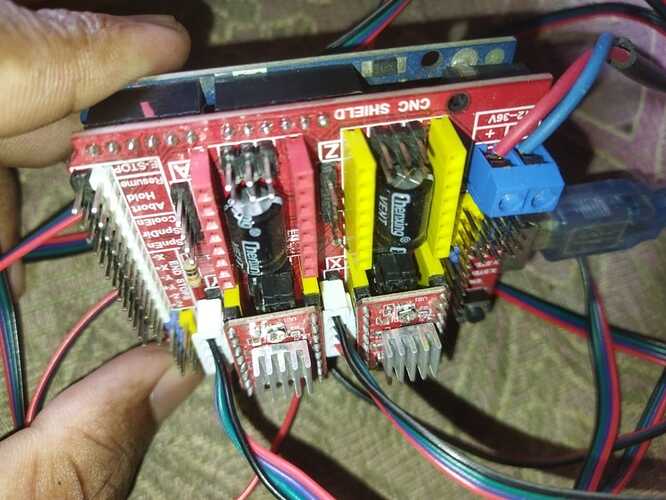

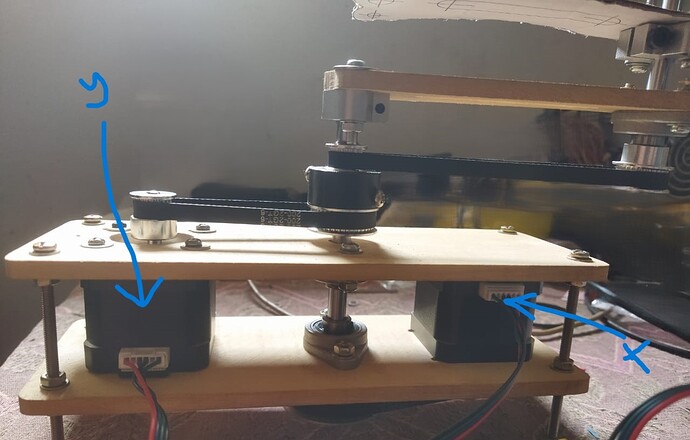

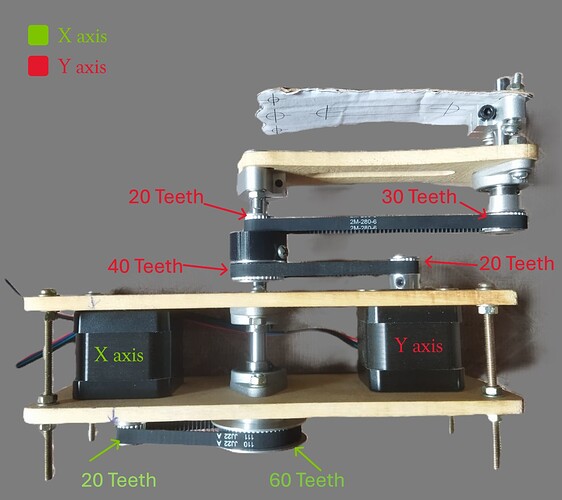

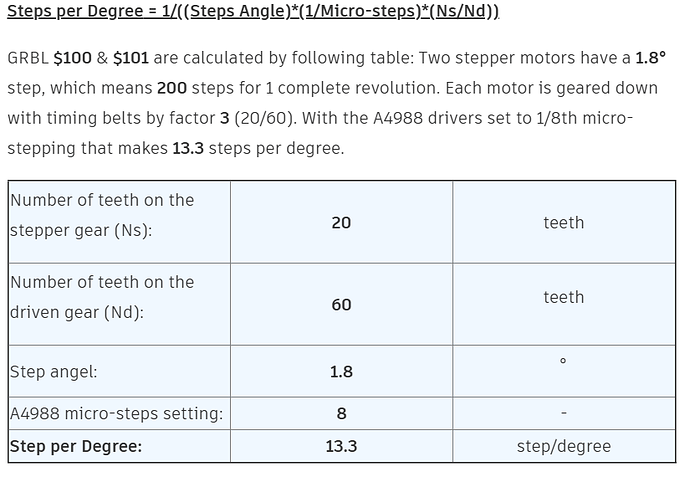

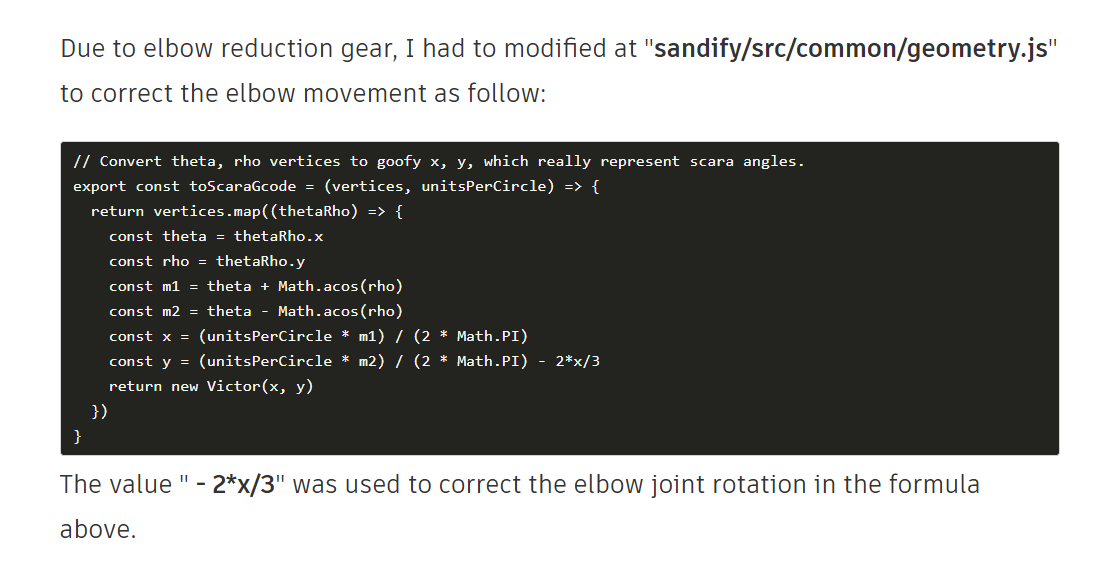

and images of the robot (arm length=115mm, cnc shield microstep resolution = 1/8, Gear ratio of both axis 1:3)