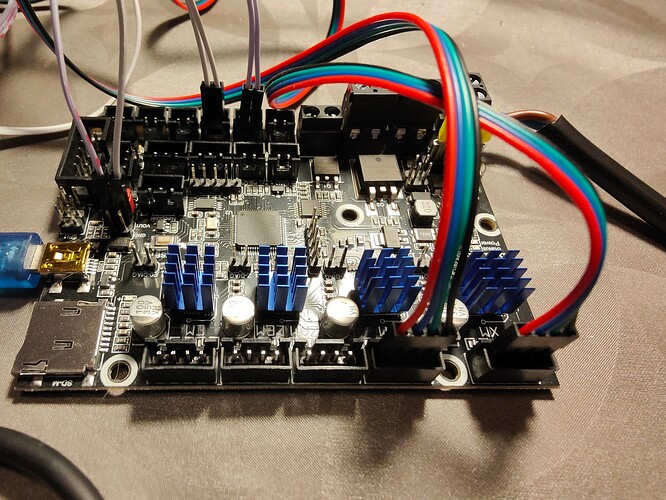

I have a small problem when I make a home, the motor shakes but does not turn.

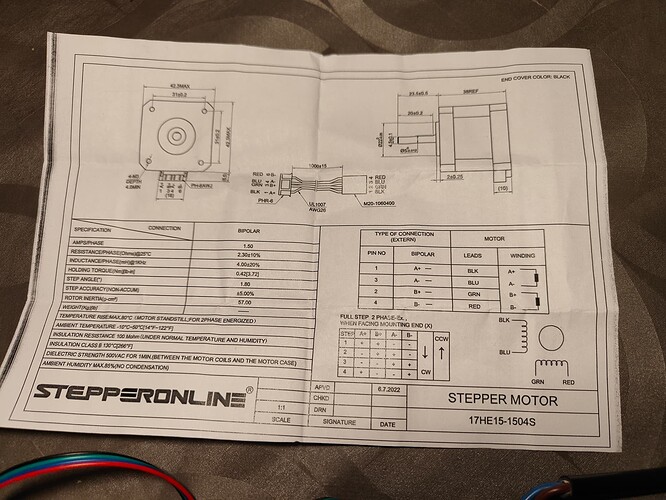

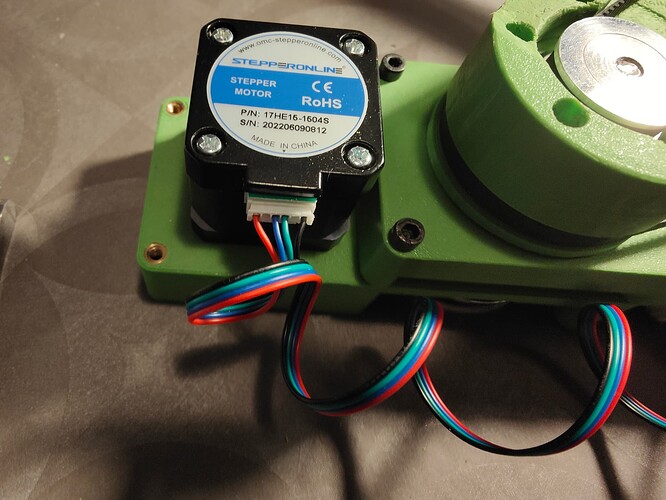

the motor wiring on the board is not clear to me, 2B/1B and 2A/1A on the board corresponds to +B/-B and +A/-A on the motor?

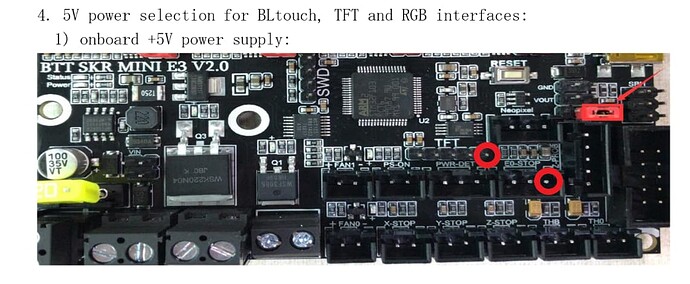

the optical sensors do not light up, bad connection? 3.3v or 5v or Klipper config?

Check your wiring.

The motor phases seem wrong.

According to the Motor datasheet, your motors are wired ABAB on the 4-pole connector but it should be AABB. Swap either the two outer or the two inner pins with each other.

The polarity is not really important, that just defines the motor direction.

Check the endstop wires as well, the marking on the Wires you connected to VOUT looks more like GND to me. Although wire markings on the cheap optical endstops dont have to be right. check the markings on the PCB to be sure.

thank you, yes it should as you say BB-AA and the non-name sensors are well in 5v, i checked

check the jumper next to VOUT, looks like you have it configured for external power supply - move it one over.

I use the 5V pins from the TFT and E0-STOP connectors to power the Endstops. Cant remember why but there was probably a reason i didnt use VOUT

Did you change the wiring since those pictures? Because from the pictures, it looks wrong. Swap the middle two pins.

Any AABB, BBAA will work. The consequence of wiring one coil backwards is the motor will drive the other way. The consequence of swapping the coils is it will drive the wrong way. If you wire them ABAB, then you will get nothing but stuttering.

I also don’t usually trust the colors. If you want to make sure two wires from a stepper are part of the same coil, you can disconnect it from the skr, short two motor wires, and (like magic), the motor will be (significantly) harder to spin. The first coil is AA, the second is BB.

I would not start with home, if you can avoid it. Just jog the machine first, and check your endstop state (M119 in Marlin) is correct before going to home.

Thank you very much for your help, my machine is operational.

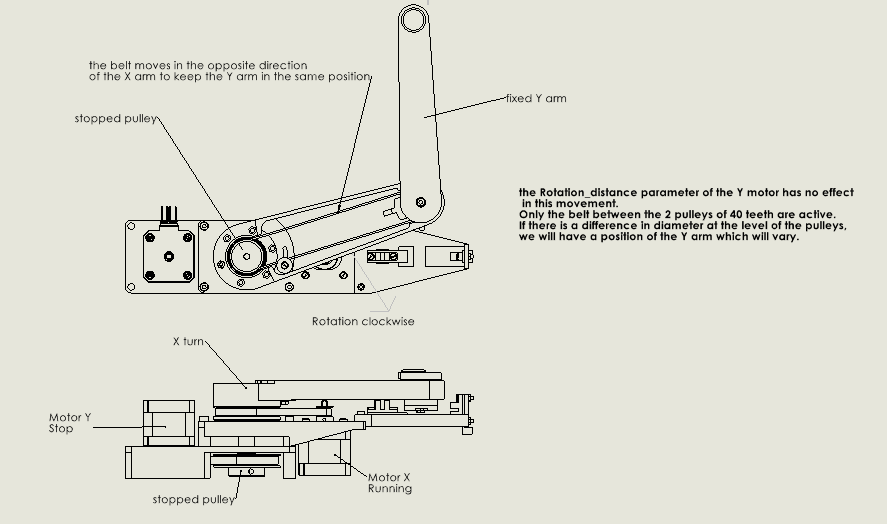

I note that I have a difference in position between X turning and Y blocked, this is surely due to the dimensions of the toothed pulleys (machined > printed)

Either I try to put machined toothed pulleys everywhere, or I redo the printed wheels, to see.

The X axis it does not matter because we can compensate it with Rotation_distance in klipper, you just have to see the pulley printed on the Y axis, a small modification to make.

Hallo maxxou89

cooles Design der Mechanik, gefällt mir sehr gut.

Freue mich schon dein fertiges Projekt zu sehen.

servus

Klaus

So the Y-arm does not return to the same position after one full rotation of X? I am not sure if I understand you right here.

If the printed pulley on the Y axis has a different number of teeth than the machined pulley in the center, the Y will not be independent from X-movements.

Or the belt may just slip if there is no tention on it.

thank you Klaus, your model is also very cool

When the X-arm rotates 90° with Y-arm at a fixed angle of 90° and then I rotate 90° the Y-arm, I don’t have the same position if the 2 arms rotate together?

I need some advice on the size of the ball.

I currently have a ball of diameter 10, 12.3 and 15.

I suppose that the ball of 15 is more appropriate for my surface diameter 650 maxi.

I disassembled a hard drive and the magnet is fine, but there is a large contact surface.

Try the magnets with some test assembly. Get a plate with the same thickness as the one you want to use in the table and test if you can slide the ball around with some resistance from sand.

Bigger surface area tends to make the ball more “spring”, meaning it will easyer be deflected. That may give you some wobbly lines. In general, I would reccomend to use a round magnet to have the same amount of wobble in all directions.

The size of the balls is mainly personal preference I tried ball sizes from 6 to 20mm on my Table with drawing diameter ~540mm. Now I use 8mm. Try the ball sizes when you draw your first patterns.

Huh?

The order of operations should be irrelevant.

Maybe some sketches would be helpful to better describe your issues.

OK thanks

I will do some tests

Hallo

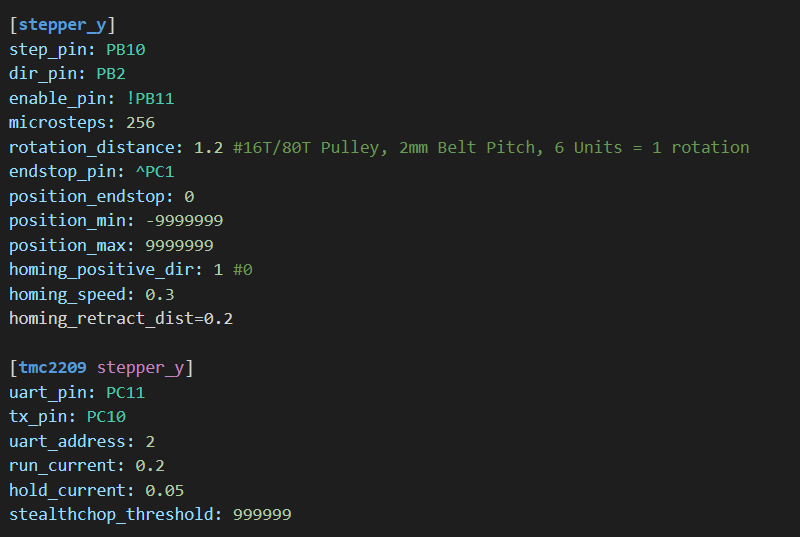

Kann es sein dass dein Haltestrom zu gering ist?

Deswegen dreht sich dein 2.Arm ein bischen mit.

Oder du wartest zu lange mit einem Befehl und der Haltestrom ist abgeschalten.

Ich habe den Motorstrom oder besser gesagt die Haltezeit mit M84 auf 340 (sek) in Marlin verlängert.

Da du Klipper Verwendest sind deine Einstellungen ein wenig anderst.

Was hast du in “hold_current” in der config?

servus KlausThe adjustment to have a perfect rotation of the arm of 6 units.

I do it by eye by iteration with indexes on my machine but I guess we can do it precisely with Gcode commands?

Bonjour Klaus,

oui j’ai cette commande dans Klipper.

Mon alimentation du RPI est un peu faible, Klipper m’informe quelques fois que la tension chute à 4.65V (j’ai pourtant une alim 5V3A )

Sure - here is an example:

G91

G1 X6

G1 Y6

G1 X6 Y6

G90

What does it do?

G91: puts the coordinates to relative coordinates

G1 X6: rotates the x-arm by 6 units or one complete rotation

G1 Y6: same for the Y-arm

G1 X6 Y6: both at the same time

G90: puts the coordinates back to absolute cooridnates

you can increase the motor currents and see if it helps

e.g.:

run_current: 0.5

hold_current: 0.2