I do not have a raspberry pi. If I wanted to do it this way do I have to get a raspberry pi?

I will try and download that sketch you linked. I could not find a sketch that would just load onto my board.

I think we have the same ratio for our gears actually. My micro steps are very similar. I also got 1600 with the math and then I fine tuned it and found 1618 to give me exactly the right rotation.

so I copied the setting you had exactly on my computer at work and sandify worked here. I checked the gcode and it is extacly the same as the file you uploaded…

I am almost 100% sure I did the same procedure at home but maybe not?

I am off in a few hours and I will try the gcode at home again and see what kind of result I get now.

WE GOT IT!!!

That is so exciting

So I am not sure if this is a thing or not?

One of my motors points up and the other one points down.

So the wiring for each axis is different I guess?

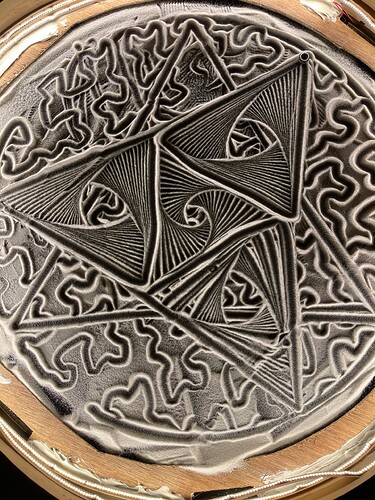

And for sandify i needed to export as Scara and have a value of 1 for RHO.

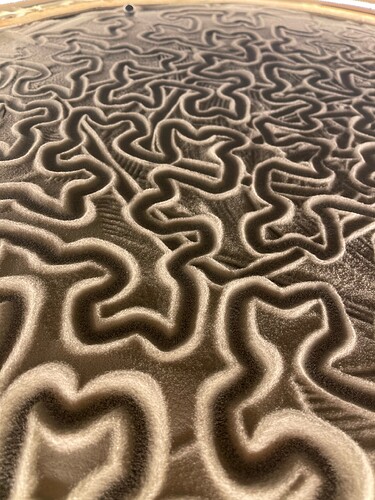

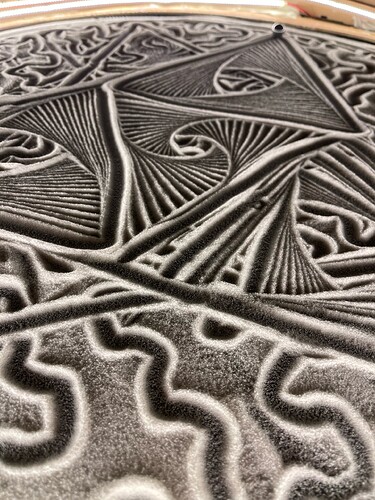

CHECK IT OUT GUYS

Thankyou so much everyone

Now to finish the table up and get end stops working and a way to talk to the bot without plugging it into my computer

That looks an awful lot like a square!

Two things I noticed:

- Is that scale about right? Try increasing the initial size of the shape so it fills the preview and make sure that ends up with a full size on your machine.

- I think both motors are reversed. The square should drive clockwise 1/8 and then drive counter clockwise through the square.

scale seems right to me. These other ones I did filled the area the bot could reach.

the image might be mirrored but I will double check on this.

You guys are literally the best thankyou so much for all the help. I am not sure what did it in the end. I did a fresh install of google chrome. Fresh install of Arduino ide. Fresh install of GRBL and UGS. I found the motors plug into the CNC shield in opposite directions ( at least with my build)

I still have a few things to work out here! I have to make the felt I have underneath the sand have 0 overlaps ( the ball gets stuck on the little ridges). I have to adjust the voltage for the drivers. I have to finish the wood working for the rest of the table and find something to put on top of this for a lid. I have to tidy up the LEDS and put them on a relay with a switch. I have to get something that will allow me to connect wirelessly to the table. I only want one power cord coming out of it.

Those sound like good problems to have. Congratulations. Have fun.

That’s compensating for the one pointing up and the other pointing down. Generally “flipping” the plug reverses the direction of the motor. Reminder to power down the whole system before changing any motor wiring.

Yep i learn slow and it cost me 4 drivers. If my memory was 1 second faster i would save tons of time and monies. Take the time to think out the moves before you start. I wish i did😡

Hi Guys, This thread has been very helpful for me. I’ve managed to get from little to no movement of my machine up to being able to run Gcode from sandify, so thank you for all the information posted thus far. my machine is a SCARA bot very similar to the one posted here by Codoje

I’m currently having issues going from one file to another as I’d like to home the machine first, however because the motors can spin infinitely, G28 commands amount to the machine spinning repeatedly for long amounts of time until it counts its coordinates back down to “0” . Does anyone have any ideas how to avoid this? thanks in advance and again thanks for the help getting my bot up and running.

If you’re using Marlin as the firmware, G92 can force reset the coordinates.

In at least one of my scripts, I added gcode to reset the angle coordinates to reduce the angle to the remainder of 2pi.

If the shoulder was at 630 radians, then you could subtract 1002pi (about 628 radians) and reset the shoulder with G92 X2. If you then commanded G1 X0, it would only rotate 2 radians.

This is an example of how I think about it. But there are still the tricks for units and you need to know where you ended up to be able to do that quick math. At the very least, you could open the text file and do the math yourself at the end.

If you need more details, tell me what you didn’t understand and I will explain in more detail. Communicating geometry in text is hard, especially if you don’t know the audience.

Thanks for the quick reply.

My apologies I neglected to specify that I’m using an Arduino with Running GRBL1.1, being controlled by a Raspberry Pi running Octoprint with Better GRBL Support Plugin. I was trying to zero my coordinates at the end of every gcode file with a G92 command but it was causing the starting position to be a little off center or a little off the perimeter which made the designs not centered

If you do the math with three decimal places, it shouldn’t be noticable.

I can’t remember if grbl has G92. But there is a similar command. G10 or something.

Okay will give it a try. Thanks!

just an update, in case you’re interested. I used the built in script keywords on Sandify to set the zero point at the beginning of each file with the files first coordinates.

(G10 L20 P1 X{startx} Y{starty}) this way each file starts where the previous one ended.

This has been working very well with a few minor tweaks to a few lines at the end of each file