I’m new here!! I wish I found this website sooner it would’ve saved me ALOT of time.

I’ve read the wikis, forums and stuff I’m still confused.

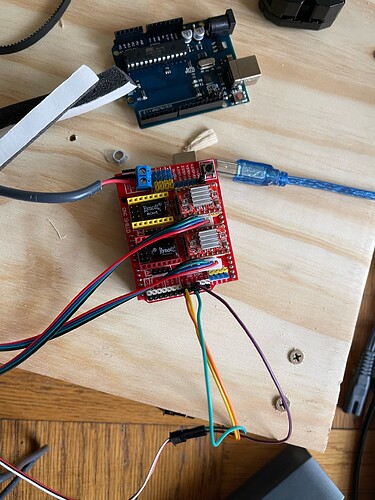

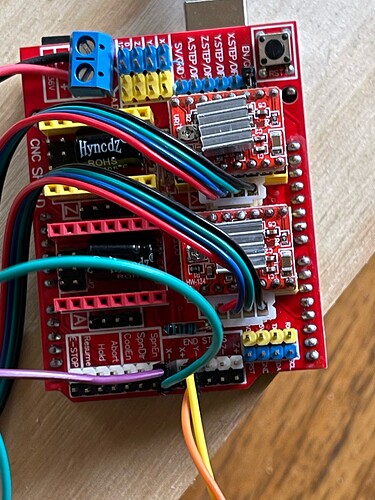

I’m using an Arduino uno with a cnc shield and two nema 17 stepper motors in a scara config. I also have two optical end stops.

I’ve flashed 1.1 GRBL to my arduino. ( I was trying to get the GRBL scara working. GitHub - jared-hughes/grbl-scara: Modification of grbl that computes motor steps based on a SCARA coordinate system. Grbl is open source, embedded, high performance g-code-parser and CNC milling controller written in optimized C that will run on a straight Arduino I flash it and my board won’t connect to my gcode sender)

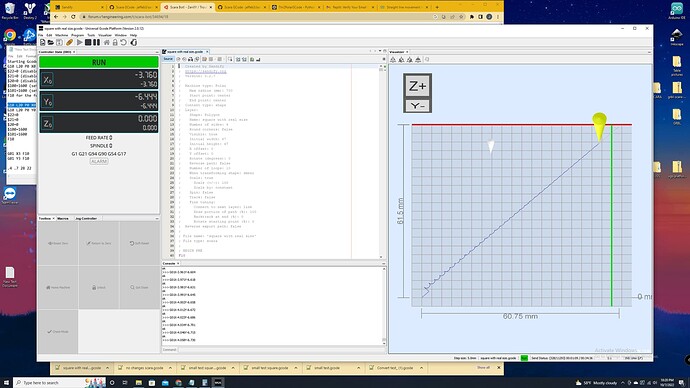

I’m using sandify to get gcode and send that to my bot with the google g code sender I’m also attempting to use UGS. With varying results.

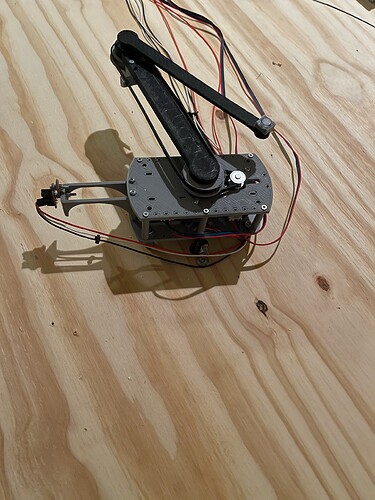

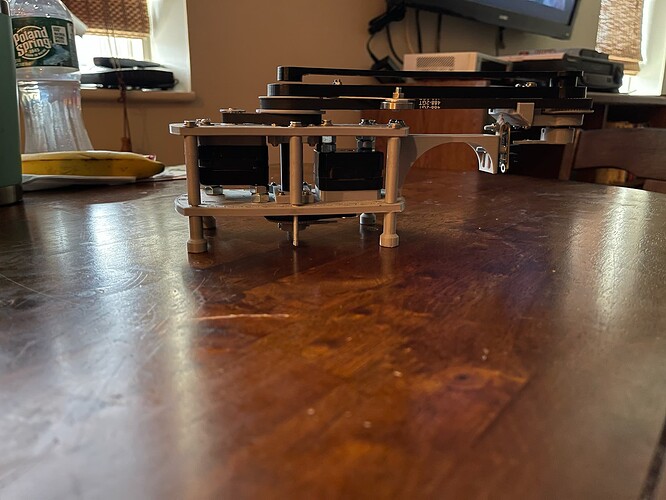

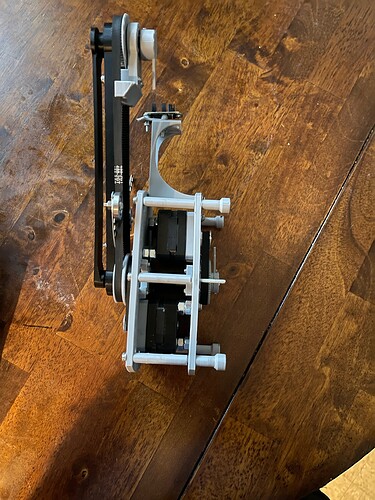

I made this scara bot ( miss mash of parts and stuff this was hard to figure out. I have a google doc with the needed parts for printing if anyone is interested.)

DIY Kinetic Sand Art Table – Always Tinkering

I finally got it moving yesterday!!! It’s been like three weeks of fumbling around trying to figure this out.

I have little to 0 knowledge of coding or programming. This was a big project to take on as the first step into anything robotic at all.

My issues / questions are…

Right now I’m getting like 10 lines of gcode and then it’s not sending anymore gcode. The bot is still moving though. Is the bot working through those lines before it sends more? I have the feed rate set to f1, that still seems really fast though.

The robot is also super loud and I have no idea why.

The long arm has no belt tensioner and I feel that belt is probably too loose. (Working on a fix for this out of erector kit parts lol)

I have two optical end stops. Do I need those for homing or no?

To enter my settings into GRBL or sandify what are the steps I should take to figure out the amount of steps per rotation? How do I enter those settings? My arms are both 184mm long and I have a 20 tooth pulley with a gt2 belt.

I recently just bought a raspberry pi maker 2040. Could I use this in the build in anyway? My intention was to get rid of the Arduino but the maker can only do one stepper motor.

I know that’s a lot of questions I’m sorry

If you could just guide me to the next step that would be fantastic.

Im mostly having software issues now

These are my parts

Optical end stops

MakerHawk 6pcs Optical Endstop with 1M Cable Optical Switch Sensor Photoelectric Light Control Optical Limit Switch Module for 3D Printer https://a.co/d/91E0Eq6

Ardunio and cnc shield

kuman CNC Shield Expansion Board V3.0 +UNO R3 Board + A4988 Stepper Motor Driver with Heatsink for Arduino Kits K75 (CNC Shield+UNO R3+Stepper Motor) (K75-CNC-UK), Red Blue https://a.co/d/0dDcRdT

Stepper motors

(These ones are technically too small for what the build called for)

Twotrees Nema17 Stepper Motor Bipolar 42 Motor 4-Lead Wire with 1m Cable 23mm 42BYGH 23MM 1.5A Motor for CNC XYZ 3D Printer (Pack of 5) https://a.co/d/2Dlv4qH

(These ones are way too big but I have both of these and I’m using the smaller ones)

STEPPERONLINE 5PCS Nema 17 Stepper Motor 1.5A 12V 45Ncm (63.74oz.in) 4-Lead 39mm Body W/ 1m Cable and Connector for DIY CNC/ 3D Printer/Extruder https://a.co/d/2sYUNgg

Belts

I have two 158 mm ones and one 488 mm one

BEMONOC 2GT Timing Belt L=158mm W=6mm 79 Teeth in Closed Loop Rubber Belt 158-2GT-6 for 3D Printer Pack of 10pcs https://a.co/d/88SGRXB

Led strip

LED Strip Lights, SMD 2835 LED Strip Warm White 3000K , DC12V 1200LEDs 16.4Ft 26000LM High Density LED Light Strips Non-Waterproof, 3 Times Brightness Than SMD3528 LED Strip https://a.co/d/indTQnu

Power supply

LightingWill LED Driver 100 Watts Waterproof IP67 Power Supply Transformer, 90-265V AC to 12V DC Low Voltage Output, Adapter with 3-Prong Plug 3.3 Feet Cable for Outdoor Use, Computer Project https://a.co/d/cv76DjS

Distro block for power

20Amp 2x10 Position Barrier Terminal Block Distribution Module for AC DC https://a.co/d/7STe1vE

Raspberry pi

Not sure if I can use this in any way