Not sure what happened but I now have a lot of play in my Z axis. I happen to notice the router twisting as it made cuts. I am pretty sure it wasn’t like this before but don’t know what could’ve happened. You can see that there is a considerable gap between the bearings and the conduit? Is there any way to move the bearings closer? Click on the links to see video of the wobble.

That is a huge amount of play. A few times with similar issues it was found that the core clamps in the back of the core were cracked or broken. I had this happen to me, though my movement was not as severe as you have.

Wow that is mms! Like it is the wrong size to emt!!

Is it both top and bottom or just top

No, it’s both

Why would the core clamps affect the space between the bearings and the conduit on the Z axis rails? I just checked the clamps and no cracks and seem tight.

You are right as I think about it, the core clamps would not cause your problem. They have been source of play, but on the gantry tubes, not where you are having problems. The one thing we cannot see in your video are the two bearings that sit behind the tubing. Have you pulled the Z axis and checked to make sure they are still correctly bolted in and that the holes for the bolt have not been elongated? If it worked at first, I probably don’t need to ask this, but are you 100% sure you 3D printed the Primo version for the 23.5mm tubing?

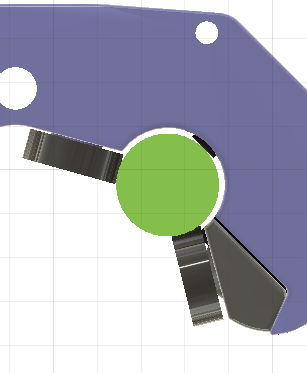

I’m puzzled by your issue, so I took a few minutes and brought the core into Fusion 360. I already had bearings modeled for another project, so I assembled the bearings, “wedges” and the core. I did it by eye, so I’m sure it is off a bit. This is what it looked like:

As you can see, there is no extra room. All the bearings are fixed with no adjustment, and 23.5 conduit model just fits between the bearings. This leaves a list of possibilities, but none make sense with respect to having a tight and working machine earlier:

- You printed the wrong core. Your core should have a ‘C’ on the back.

- The conduit is not 23.5mm

- Problem with the bearing behind the tubing like missing, or not bolted, or the bolt hole has become elongated so that the bearing sits further back.

- Calibration issues with your 3D printer

- Wrong bearings

None of these fits what you describe very well.

Did something crack? I think you need to take it apart and look at it.

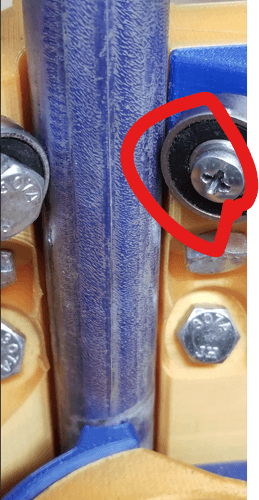

The screw holding that top bearing in looks suspiciously small compared to the bolts. If it doesn’t fill up the bearing, maybe the bearing moved. I can imagine a scenario where the screw held it down by friction, but it slid a little as it saw force.

This is definitely part of the problem. Do you have more in there? That is not the same diameter of the bearing and is allowing the bearing to move outward from the conduit!

I believe that is on purpose to allow for adjustment. The holes in the core are also smaller than the ones with bolts. I did loosen and re adjust but there is still alot of play. It seems as if the bearings behind the tubes are not even touching and I don’t think there is any way to adjust those. I also measured my tubes one is 23.5 the other is 23.3.

The holes through the core and the “wedges” are modeled at 8mm. If you find them smaller, you need to drill them out. Holes on vertical faces of 3D printed objects are sometimes deformed depending on the PLA and your printer settings. The bolts used to attach the bearings to the core should be 5/16 (which is just a bit under 8mm) or 8mm bolts. The diameter of the hole in the bearing is 8mm. Using bolts that are too small seems to be at the root of your issue. There should be little or no play by the bearings…no adjustment. You should also check to make sure the raised rings the bearings ride on are not damaged.

To quote Forest Gump “I’m not a smart man”, Tony and Riley you guys were absolutely right! I looked at the assembly guide and those were supposed to be bolts not screws. Looked in my box of barts and wouldn’t you know I had 4 bolts and 4 locknuts still in the bag. Can’t believed I missed that. The bolts had to be threaded into the wedges so maybe I originally thought the holes were smaller for screws?  I don’t know but now there is zero play, actually seems tight but it goes up and down real smooth. Thanks to everybody who responded! This forum and community is fantastic.

I don’t know but now there is zero play, actually seems tight but it goes up and down real smooth. Thanks to everybody who responded! This forum and community is fantastic.

I really love this place! Glad you got sorted!