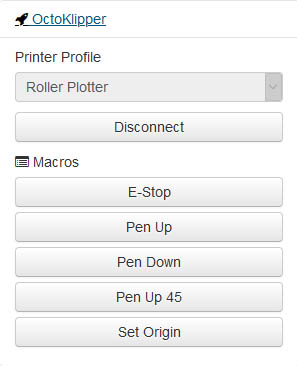

I got the bright idea yesterday to shorten the 3d printed TPU belt by 8mm since it stretches a little & the 2nd test print using it worked the best so far. I found another F695zz flange bearing, so all the idlers work great now. I can tighten the screws all the way down & they still turn nicely. I have 8 of those bearings used now, 2 for each idler. I had a loose grub screw on one the wheel motors which was probably causing part of my problem before. It is still not rolling perfect, but I didn’t see any missed steps this time. I am really liking using the klipper firmware with this machine. There is also a octoprint plugin called octoKlipper that adds a little more flexibility to it like adding button macros for specific code. Here are the buttons I made so far.

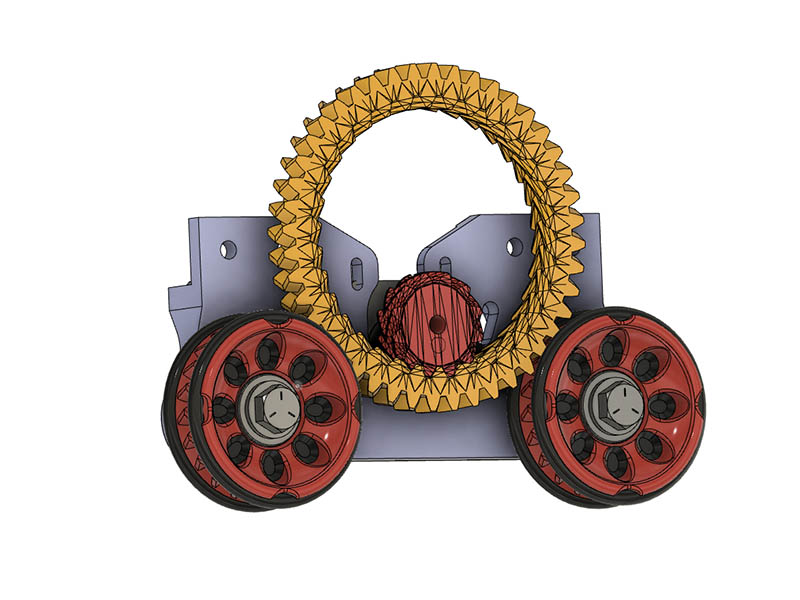

Think I figured out a way to get the correct inner ring gear draw correctly with this Ferris Wheel or I like the term Jeff used for it, a Hamster wheel. I created the drive gear & inner ring with openscad using https://www.thingiverse.com/thing:53451 I then merged that with a 44T double Helical gear for the outer ring which is 105mm outer diameter in fusion 360. I will probably have to use 2 or 3 bearings rolling along the flat part of the ring to keep it from wobbling, but will just print it for now to see how it meshes. Might have to create some sort of tunnel for it also so it doesn’t wobble the other way, but 1st things 1st. Looks like that big ring is going to be a 2 hour print. I was thinking I could put a idler bearing gear on those end V-slot connections, but the distance is too short to get a gear in there with the current specs I am using.

5 Likes